Teslabolt

Members-

Posts

80 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Teslabolt

-

-

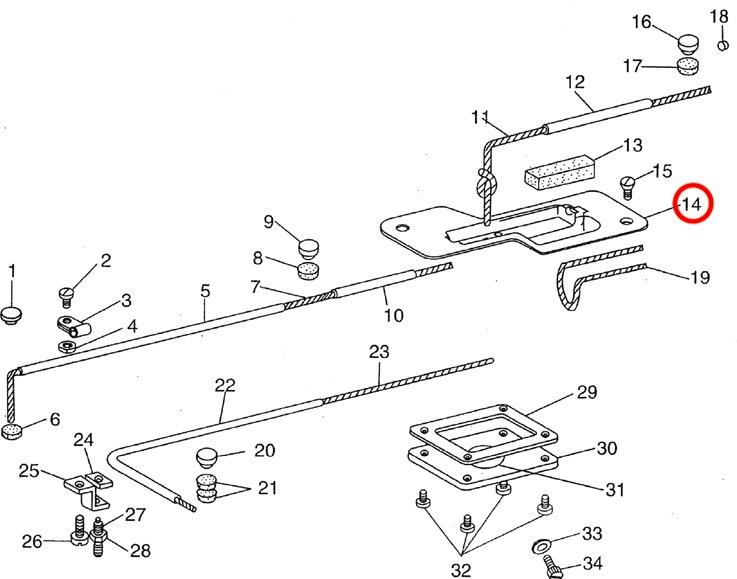

I will check... Great article, RussellJohn. I have checked everything in that article and I have the pin (not sure if the length is correct -- can some cross-check pretty please??) My tension release slide is not broken or bent. seems like either the pin is not long enough or there is some issue with the thread controller disc. part #26

-

Sorry, forgot to mention that I tightened it to the max, and it did not even come close to touching it.

-

Yes, the pin is inside there and it moves. Here's another video. I am manually applying pressure to part #13. When it moves, the plates move out like they should. Second part of the video, when the foot lift is up, the pin moves about 3mm, but clearly that is not far enough to engage the plate.

-

-

-

-

Will do! Will that resolve the issue of the pin?

-

I am having a myriad of issues threading my new to me used Consew 206RB-1 - the Lower thread is very loose. See pics. Watching other videos on how to thread the machine, there is one where the YouTuber states that when the foot lever is up, it will release the tension on the discs. Well, mine does not and I can't figure out why. See video.

-

My oil reservoir is missing. Is it necessary on the 206RB-1? This parts list is for a -5 so I wasn't sure if the -1 even has it. Thanks!

-

206 RB-1 Knee Lift/Presser Foot Pressure

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

I was able to adjust the lifting shaft that runs from the top spring bar down to the bottom. I also moved the knee lift over and re-positioned the hardware on the knee lifter assembly. -

206 RB-1 Knee Lift/Presser Foot Pressure

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Here is a video of the backside. Is the spring bar supposed to be hitting the large black screw? You can see me struggling to lift it. Very stiff. -

Getting ready to install my knee lift. The knee lift bell crank is very difficult to move up by hand. Is there an adjustment for this? Or is it normal? It does seem like the feet are leaving too much of an impression on the leather (4oz) Am I correct that the knee lift bar needs to contact at this point in the photo?

-

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Perfect. Thanks, Gregg! The takeup lever isn't quite at its highest position when the dots are lined up. It seems to be about an inch off on the wheel if I hand turn it until it is at top dead center, so to speak. Do you by chance have info on how to adjust the presser foot pressure for the -1? -

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

-

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

I have not installed the pedal linkage or the knee lift yet. How do I adjust the height with the bumpers? -

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Great, thanks so much for the response, nylonRigging. Is there supposed to be an oil pan on mine? Also, there is no "head post" sticking out of my table to rest the unit on when tipped over. Does anyone have an idea what I can use? Wondering if the missing oil pan is the reason that this thing doesn't sit flush with the table. -

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

-

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Finally got it out but sliding the spring mechanism one way. Isn't there supposed to be a spring inside to provide tension on the spool? -

How to remove bobbin case from Consew 206RB-2

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Good question. I had the needle in the upmost position. Thanks for the link. I have seen that one. That video just shows putting it back in. Can't find any that show how to take it out. -

Newbie here. Just took delivery of my first sewing machine. 206RB-2 Can anyone point me to some decent videos on how to thread a Consew and how to remove and thread the bobbin? Several videos, but they are all telling me something different or not getting in close enough to where I can actually see what the heck they are doing. Thread kept fraying and snapping as I was moving slowly through some 4 oz leather. I broke an "ear" off of the front of the bobbin trying to remove it so I also need a recommendation on where to get a new bobbin case. Ugh - the trials of learning something new. Good times. Jeremy

-

They sell 12.5mm dies for $12 with shipping

-

Has anyone had any luck with these? Tough to believe that they are as good as the $120-$190 one sold at Tandy and Buckleguy. https://www.ebay.com/itm/Universal-Manual-Press-Machine-Stud-Rivet-Setter-Dies-Tool-Hand-Press-Grommet/264541050596?hash=item3d97e016e4:g:NY8AAOSwcydc8Mp-

-

Hey everybody. I could use some assistance figuring this out. If I want to be able to consistently stamp these coasters, for example, what would you guys do? Assuming some sort of jig. It seems like it would be nice to be able to attach my brass stamps (threaded) to a modified ram for the 1 ton HF arbor press. Thoughts?

-

Deciding between 206RB-1 VS 206RB-5

Teslabolt replied to Teslabolt's topic in Leather Sewing Machines

Will I be okay sewing 3/8'' occasionally? I saw that the Thor, in the same class, has a dial on top that allows for extra room in between the needle and work.

.thumb.jpeg.673330fbe3a9ca67548c106b72eeb1bc.jpeg)

.thumb.jpeg.d2cd37d3a46cd7e891baadb11d024bde.jpeg)

.thumb.jpeg.19dcb650b842cc331af2908687e544f5.jpeg)