jrprottas

Members-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jrprottas

-

I'm not finding the free ebooks on tandy's site. do you have the url? thank you so much

-

Thanks for your input. How did the cobra 4 compare to the newer cowboy3200?

-

great lead. thanks. I'll check them out tonight

-

That's partly why I'm asking for feedback- unfortunately I havnt seen any of these up close.

-

Mostly backpacks and bags from vegtan. Multiple layers of 6 oz leather. So I have narrowed it down to a cylinder arm, and if new, to one of the clones: cowboy 3200, techsew 2700, cobra-4, Artisan Toro 3200, etc capable of 1/2" to 7/8" thickness. For reasons of space, noise and cost I'm considering one of these manual machines. I would prefer spending $1600 for a manual rather than $2350 if a manual can meet my needs Really asking opinions from users as to how these manuals compare to the electric clone machines. thanks

-

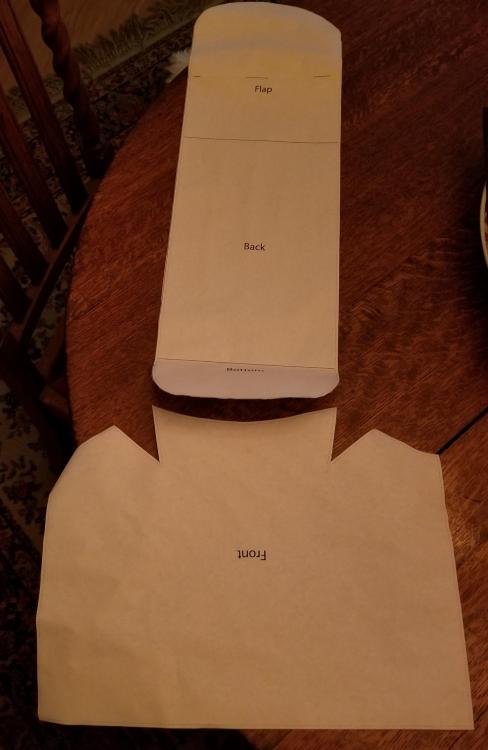

Below are a couple of photos of a Saddleback Mtn. backpack that is said to be made from only 2pcs of leather. The flap, back and bottom in one piece; and the front and sides from a second piece of leather. A friend created the template on a CAD program the dimensions of which don't work. Does the template design reflect the correct approach? Is there a formula for creating the darts? viz width and depth measurements? Or a straightforward explanation of how to tinker with pattern to make the pcs fit together?

-

Looking for feedback about MANUAL sewing machines like the Tippman Boss, the Outlaw and my current favorite choice: (solely because I would still have the option of adding a motor, table, pedestal stand down the road) the Cowboy 3200 HC portable. Apparently, all are capable of 1/2" thickness of vegtan leather and are capable of a corresponding thread weight for this type of sewing. This would be my first machine. Can folks having experience with these machines offer your input? Did you buy it new or used? How reliable has it been? Would you buy it again? Are there patchers (?) or other machines to consider? Should I wait until I can buy an electric clone instead? Thanks in advance for your time and opinions. Jeff

-

wow. thanks blue duck for your time in explaining this. So if I understand, the folds are a design element accomplished by making the front width a little greater and gathering the extra length at matching anchor points. BTW, you're right, the back doesnt have the folds. Further, the rivetted bands on the sides may, or may not have a pocket behind them, as they may simply be a design for attaching different sections of the gusset? Honestly, you have cured the many obsessed sleepless hours with your single post, and I'm indebted to you. Lacking the actual construction experience it's difficult to conceptualize some of the bags I see, and would want to emulate. And obviously, most bags do not show photos of the bottom. Would you consider solving my only other riddle causing my lack of sleep? I'll post the question and photos after my old man nap. thanks again mr duck. Jeff

-

Here are photos of a couple of my favorite maker's messenger bags, used as examples of my bag construction questions. Newbie who has so far only made prototypes out of thin pleather. I'm still trying to figure out my design for a "turned" construction, 6 oz vegtan, small (8"w x 14" tall) sling bag. Can you see how these were constructed from these pics? I see a front and back, with a single side piece??? Perhaps a second side piece that only creeps up from the bottom 6" creating the side pocket with the banded, riveted edge and reinforcing the bottom. My main question, since I have no actual experience: These bags appear to have the same design but in the first photo it was necessary to have the puckered folds; and in the last photo it was unnecessary. WHY??? What design principle would eliminate the need for puckers, folds and/or darts? Does the first design have a larger, rounded corner. Would that explain the need for the folds? How would one "anchor" the folds so that they look the same on both sides? Stuck, Jeff

-

Hi folks. I'm not sure what caused this staining on my Hartman overnight bag. Guesses range from water to sun tan oil. I'd prefer removing the stain and returning the area to closer to the rest of the bag. Any suggestions? Is there a treatment or approach that would make the stain blend in, possibly adding other dark areas that would make this stain appear planned, with an overall mottled look? Otherwise, I'm open to darkening the entire bag to match the stain. Do you have ideas for this approach? Sorry to be so wordy for a post that could have read: how do I restore this?

-

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

Click to Enlarge HERES WHAT THE ARTISAN WEBSITE CLAIMS. Seems to cover a broader range of thin to thick applications. Again, anyone have experience with the TORO ARTISAN 3200? Heavy Dutyartisan® TORO-3200 Stitchers with a 12 1⁄2" working area cylinder bed are known as Compound Needle Feed, Walking Foot (Unison Feed) Lockstitch Sewing Machine and include a very large size Bobbin and Oscillating Shuttle Hook system designed to stitch from as light as 2 to 3 sheets of paper, up to as heavy as 9⁄10 inch or 24.1 mm thick. Some features of theartisan® TORO-3200 include a lever type stitch regulator with Reverse feed and a built-in bobbin winder mechanism. The machines stitch using threads manufactured using bonded twisted Nylon or Poly Threads from light weight sizes such as z-69 (tex 70) up to as heavy as size z-415 (tex 410) industrial threads. We recommend genuine SCHMETZ brand Needles from diameters as light as 794 NM110, (#18) up to NM250 (#27) including leather point needles 794 S #21 to #26 and 794 D #23 to #25.artisan® is the direct distributor of Schmetz brand, German manufactured highest quality needles and carries all of the various sizes. -

Thanks. I didnt know that Tandy had a press for fasteners that would also do logos.

-

How do you execute your Maker's Mark on leather? I will be using 90% Horween leathers. No foils at this time. Just consistent crisp logos. Will a simple arbor press produce decent results? Does an adjustable heated arbor press produce far superior results ie is it worth the investment in your opinion? If you're be so kind show us a photo.

-

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

Wiz mentioned the Toro Artisan in one of his stickies and I finally studied the website. They're located in ca which is great. Anyone with experience with the 3200 they offer? They claim its proficient with thinner leathers also. For example wallets. -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

thank you. Its not just the weight...also the space it takes up and to a lesser extent, the noise. At 70, I can still wrestle around 100 pounds myself. Also the entry level price that doesnt preclude adding things in the future as I get a better sense of this new hobby. Sure seems to be a more flexible choice than a Tippman or Outlaw. what are barney handles? Would they make any machine hand-operable? -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

Wiz. You're right the Cowboy 3200 seems to meet my needs best and your info hasnt steered me wrong yet. Are you familiar with the CB 3200 HC portable. It would save me a few dollars upfront, and address the weight issue. It would seem it wouldnt preclude getting the standing pro-stand and servo down the line....on the surface no downside. What do you think of this idea? Thanks Jeff -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

Thread/needle sizes for industrial machines are theoretical at this point, as I've learned theres not a direct correlation between saddlestitch needles/threads. What would you recommend for small backpacks? Is #207/#25 a safe bet? -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

You guys are awesome. I've learned so much from your stickies and posts. I'm new to leather machines. Expect to be a hobbyist more than a retailer and will not use the machine daily. I think I'm looking for: walking foot - triple feed cylinder arm with optional table #25/#207 capable M bobbin 3/8 to 1/2" vegtan penetration Would like to have a machine weighing far less than 200 pounds with the above specs. Am I dreaming? -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

As a newbie I had just figured out that Maine poly thread sizes .035 to .045 with John James Harness needles sizes Size 01 and Size 00 (also known as 2/0) would pair nicely for my turned backpacks. I'm totally lost on your thread/needle chart as to how to find equivalent pairings? How does the lockstitch compare to a traditional saddlestitch in terms of strength? -

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

I had thought these brands (CB, Cobra, Techsew, Consew) were the best of the best. Can you provide specific cylinder arm models of Juki, Adler, Seiko, etc for straight stitch sewing for 1/2"+ layered leather sewing? If really 2 to 3 times more expensive these may not be in my future, but would appreciate learning about them. -

Beautiful work! How wide is the strap?

-

Best Sewing Machines- New vs Used/Antique

jrprottas replied to jrprottas's topic in Leather Sewing Machines

Wanting some recommendations in these categories: I'm new to leatherworking wanting a machine to do heavy duty (10+oz) straight stitches for backpacks. NEW:. Are there other top contenders beyond Adler, Cobra, Cowboy, Techsew, Sailrite, Juki? Are decent new machines necessarily in the $2500-5000 range? Are there industrial machines that dont require daily oiling? USED/ANTIQUE: It seems very difficult to find used Adlers, Cobras or Cowboys. Are there some "sleepers" in the used market worth searching out that may be more available? Singers for one seem quite abundant: are there series 201, 301, etc to look for for my purpose. Any models to stay away from? Are there older classics worth seeking out? -

Thanks Fred for your input. Which of these holds the shape better? I'm afraid the #1 3pc would sag. Are the side gussets enough to hold a squarish shape? With a continuous front/back do you have to crease the front and back edges to square it off? Or add a rectangular bottom piece inside the bag? Thanks again

.jpg.08ec196edf69bf31b2617ffbc3419698.jpg)