CalypsoReCreations

-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CalypsoReCreations

-

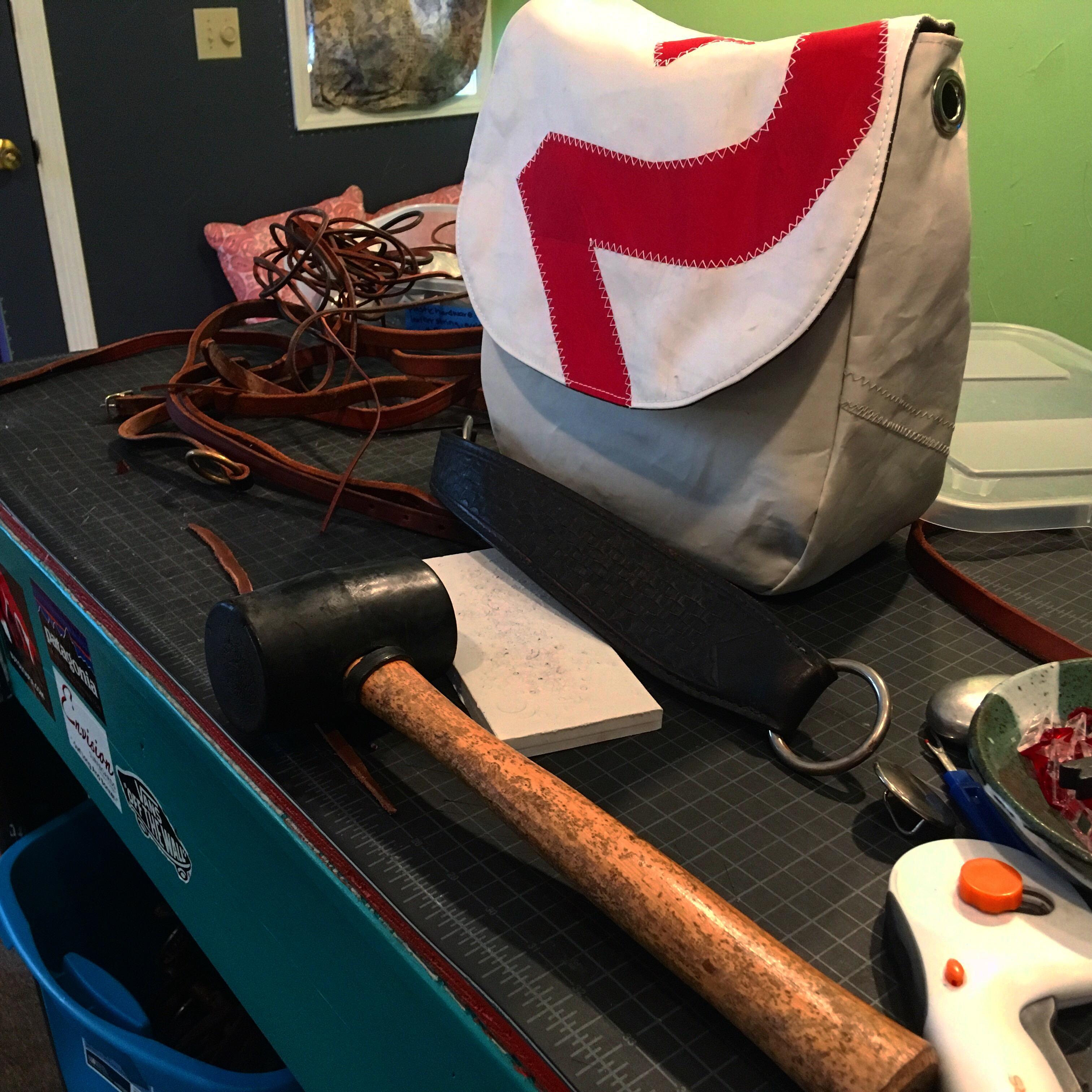

I am currently hunting for the best cylinder arm industrial machine to help me make handbags and the like. I sew with sails, waxed canvas, marine vinyl, and salvaged horsetack. I’ve looked at many machines, and am feeling a bit overwhelmed. I like the Cowboy CC2B7R, The Sewline SL-335, the Singer 153 B8B, and the Pfaff 353. I’ve also researched a few TechSew machines. I’m worried about overkill! Lol! But, I want a machine that will hold layers of mixed fabrics as it sews, and one that can sew through up to 1/2” of fabric. It only need sew through one layer of 10 oz leather, but with one layer of 6oz Dacron also. I currently have a Viking 6270 and a Sailrite LSZ-1. I push both these machines to their limits. I push the Sailrite a bit too far. Help?!