mmason

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

Colorado

-

Interests

Sheridan

LW Info

-

Interested in learning about

different styles of tooling

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

mmason's Achievements

Member (2/4)

-

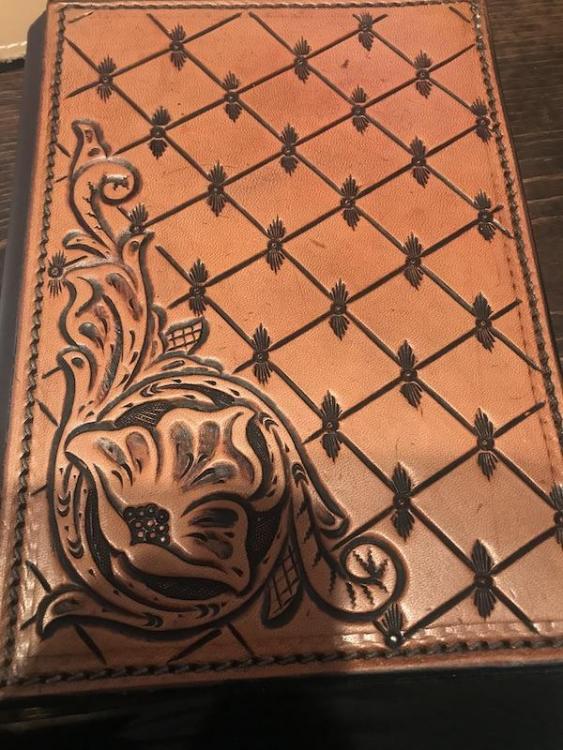

I had a money clip from patriot (the electric cattle fence company) that was a wallet on the inside with horizontal card holders but was also a money clip. I never made a money clip I would always make roper wallets because I could hold a bunch of cards. But I liked the look so I took a stab at trying to make one with some tooling on the outside pocket.

-

I’d love to use brass but it was expensive compared to metal. But a lot of people use brass and aluminum, I kept melting the ring before it could get hot enough so I switched to steel. The whole thing is static and the only part that swivels is the ring on top. Wich I Drilled and tapped a 3mm hole in the 1/4 rod that goes into the ring. Then I used a small flat head screw To hold the bearing and turned it flush with the lathe. Then used lock-tite to glue it into the ring .

-

the barrel is 5/8, (I made one in 1/2 in also works the same) and the hole drilled through it was 1/4. the rod that goes inside the barrel is 1/4 and the bearings I picked up a long time ago on amazon they are called mini bearings (I think the size was 3mmx6mmx2.5mm the bearings where just a hair bigger than the 1/4 rod). the saddle I used a 1 1/4 rod and drilled it out till I can get a lathe tool to increase the hole diameter. the tube that holds the bearings is 3/8 rod drilled for the bearings I believe i used a 1/8 drill bit. the set screws I picked up where 10-32 but I would probably use 6-32. I used oxy-acetylene torch and bronze brazing rod with flux to braze the tube for the bearings and the saddle together. If I forgot any measurements let me know -Matthew

-

Hi, I made a purse using a saddle bag style template i had and was wondering how much i should price this at? any suggestions?

-

-

I enjoy the ring more, especially since its hard to find a knife that fits my finger. I did think of TIG but its a little pricey to convert my welder.

-

I finished another swivel knife and I am starting to get the hang of things. this one spins a whole bunch better than the last, it spins for a pretty good while. I tried bronze brazing this time and I like it better than mig welding and melting the saddle and warping things. I made a 5/8 barrel since my hands are not small at all.

-

for the swivel I press fitted a bearing into that tube then welded the tube to the saddle( inside the loop is where I welded it, I drilled hole all the way through) then turned the inside till it was flush.

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

-

some mini metric sized bearing from amazon i think it was around 2.5-4mm. the blade is one I borrowed off another knife to see if it the saddle spins smooth when carving.

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

-

yeah its steel, its pretty heavy which pushed me to try aluminum, Also the aluminum will cut a lot smoother.

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

-

its adjustable there is a set screw on the other side of the knife.

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

-

fixed it.

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

-

HI, I made a swivel knife on a mini lathe I bought a long time ago. It need a better finish but I am happy with how it turned out and works. I have some aluminum lying around I want to try this on, any suggestions? -Matt

- 18 replies

-

- swivel knife

- homemade

-

(and 1 more)

Tagged with:

.jpg.d60258221c476480a6e073a8805645bb.jpg)