-

Posts

21 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

United Kingdom

LW Info

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

machineage's Achievements

Member (2/4)

-

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

SOLD 🙂 -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

Now £225! £200 less than my initial asking price. Surely it has to be worth that? -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

£250! -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

Bumping - surely this has to be worth £275? -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

£275! 😃 -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

Now £300 😃 -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

£325 - going on eBay this weekend -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

Now £350! Is there any interest? Am I asking too much? -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

machineage replied to machineage's topic in Old/Sold

Reduced to £375! -

Wimsew W-0618-1 Walking Foot Sewing Machine - Staffordshire UK

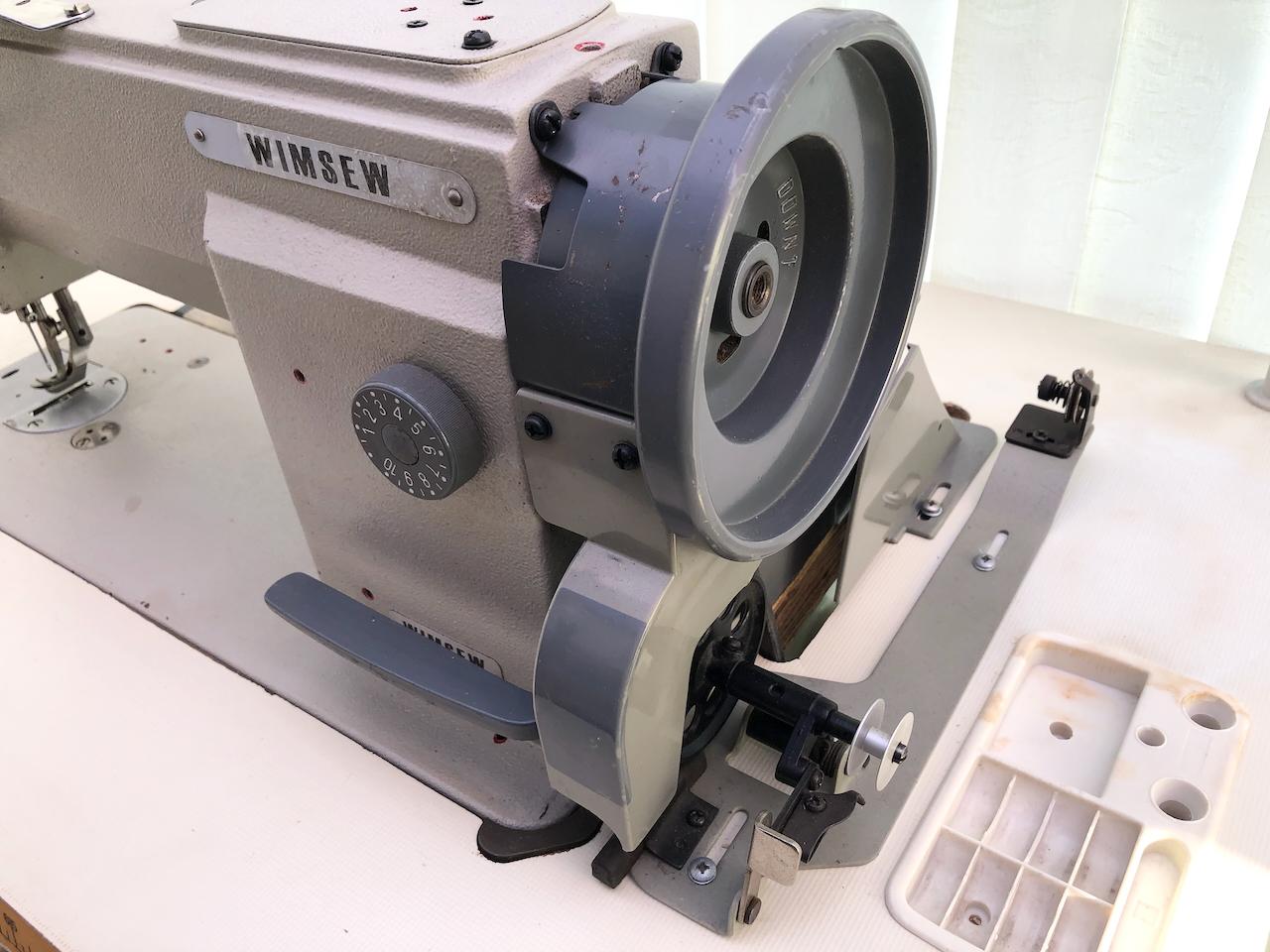

machineage posted a topic in Old/Sold

Hi all! Well, it's been a while since I posted... I bought three machines a few years ago - see: https://leatherworker.net/forum/topic/88720-newby-bought-three-compound-feed-machines-which-one-to-keep/ Much has happened since, suffice to say I've not had a chance to sort the Singer or Durkopp 🙁 Anyway, space is now an issue, so I'm letting the Wimsew go. It's a walking foot / compound feed machine. I'm sure it's the same model as the one Matt sold: https://leatherworker.net/forum/topic/84816-used-wimsew-0618-1-sewing-machine-uk/ It's working, and in fairly good condition, but may need a service. It's on a Wimsew top, but with an older set of legs without castors (can castors be added I wonder 🤔). I thought I would offer it here to see if there's any interest, before popping it on eBay. I'm located in North Staffordshire, UK. I know a personal courier who could deliver it to the south coast (Bournemouth across to Chichester), and up north to Manchester / Sheffield / Leeds, possibly York, and most places en-route to these destinations. No idea what to ask for it - advice welcome! UPDATE: Price needed as per mod. requirement. £425? Thanks! -

Durkopp Adler 239-125 Missing Oil Pan / Timing?

machineage replied to machineage's topic in Leather Sewing Machines

Thanks @Constabulary I’m drawing up my list of parts to buy for this machine from College Sewing, which include a new belt, bobbin winder and cotton stand. They looked at a Durkopp parts list to check availability & pricing, and a number of parts are not stocked or have very long lead times, if indeed they are still made. I did suggest this machine was very similar to Singer machines, but they wouldn’t guarantee any of the Singer parts fitted, and didn’t offer them. So I’ll take my chances I guess. I tried the feed dog screw from my Singer 211G166 and that fits, so I guess part #200106 from College sewing will be correct. The presser foot screw is also missing, but again the screw from my Singer fits, so I will order #201031 One of the screws that’s missing and causing problems is the bobbin case tension spring fixing screw. Whilst the bobbin case on my Singer looks almost identical, the tension spring fixing screw won’t fit the Durkopp bobbin case. It’s slightly too large in diameter. The other is the rear throat plate screw. This is the same size thread as the feed dog screws which fit, but obviously a different type of screw. Thanks again -

Durkopp Adler 239-125 Missing Oil Pan / Timing?

machineage replied to machineage's topic in Leather Sewing Machines

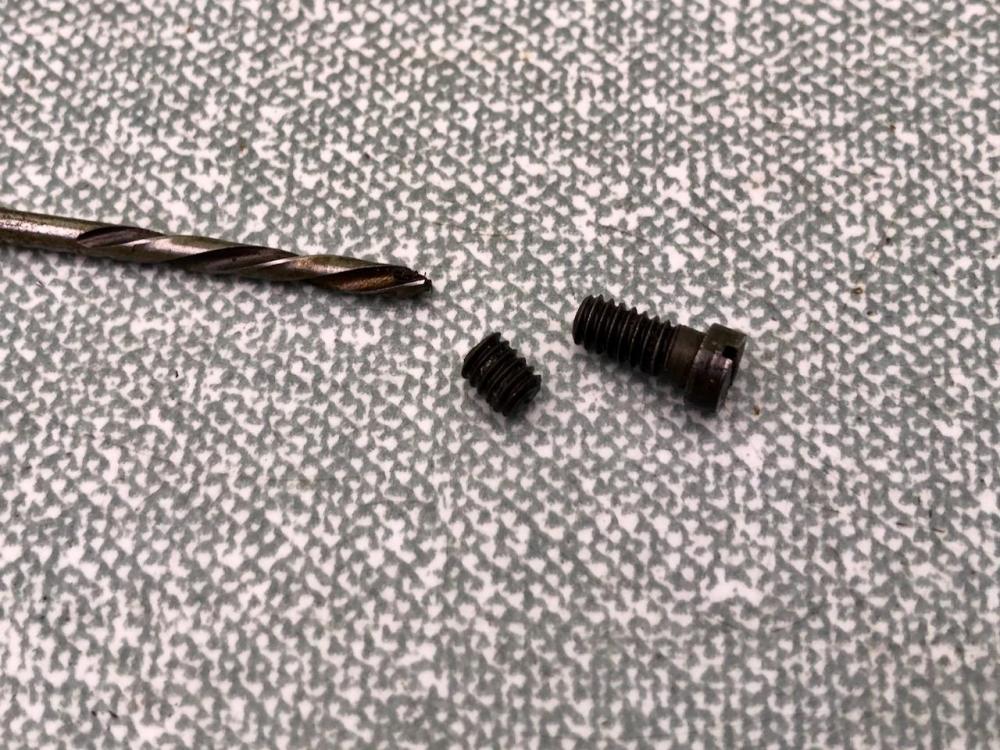

The 1mm & 2mm left hand bits arrived today. I drilled a short pilot first into the snapped thread, then went at it with the 2mm bit, and hoorah These left hand bits have gotten me out of a fair few sticks in the past, and they saved the day again! I'll source a replacement screw for the feed dog, and the bobbin, then start the process of timing the machine. -

Durkopp Adler 239-125 Missing Oil Pan / Timing?

machineage replied to machineage's topic in Leather Sewing Machines

The smallest I had was 3mm, which was too big, so I ordered some 1mm & 2mm bits yesterday. I've had good results with L/H bits before, so fingers crossed they work again! -

Durkopp Adler 239-125 Missing Oil Pan / Timing?

machineage replied to machineage's topic in Leather Sewing Machines

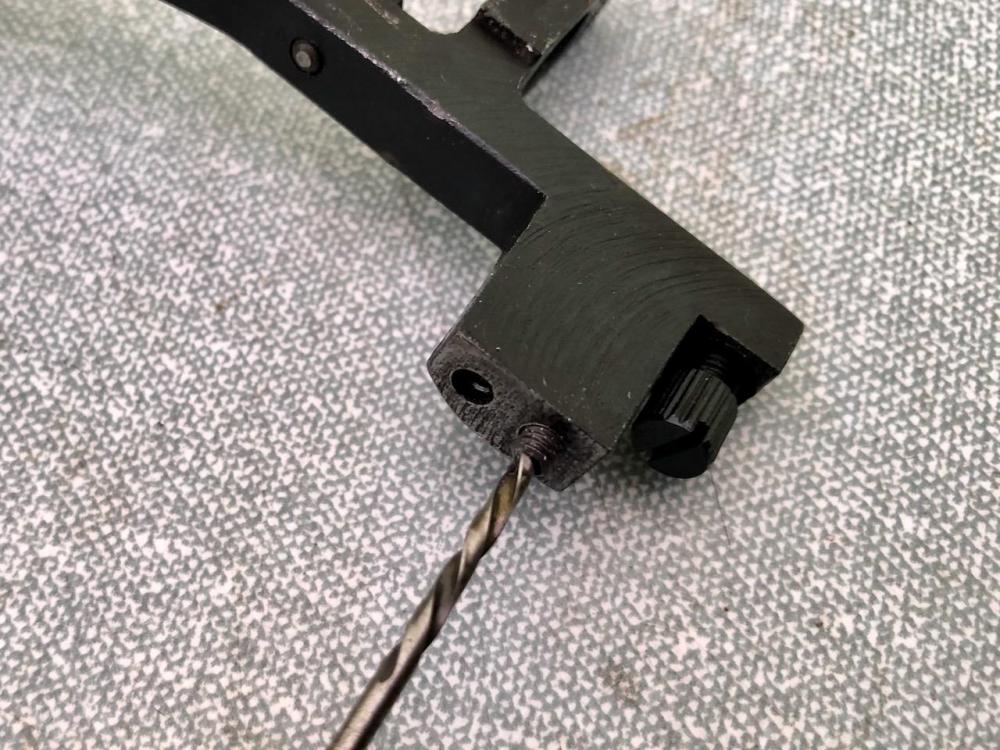

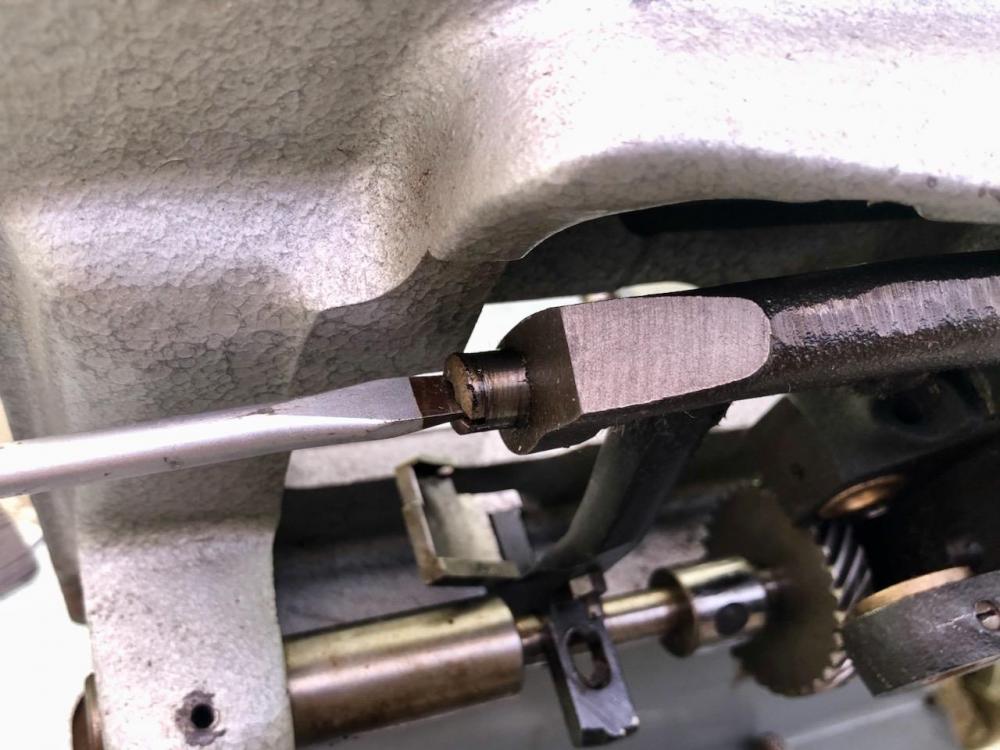

Thanks @DonInReno Some good ideas there! I really needed to get this feed bar out, it's just impossible to get decent access to the stuck thread with the feed bar in situ. So.... I removed the feed fork, simple enough. I then marked the feed drive rocking shaft for both rotation & lateral positioning where it is clamped. I then loosened the shaft clamp screws, and the grub screws for the two stop collars. I was then able to move the shaft to the left, and rotate it to gain access to the feed bar hinge screw and nut. Removing this screw released the feed bar. So now I need to contemplate removing the stuck thread! I will see if I have a small enough left-hand drill bit first! -

Durkopp Adler 239-125 Missing Oil Pan / Timing?

machineage replied to machineage's topic in Leather Sewing Machines

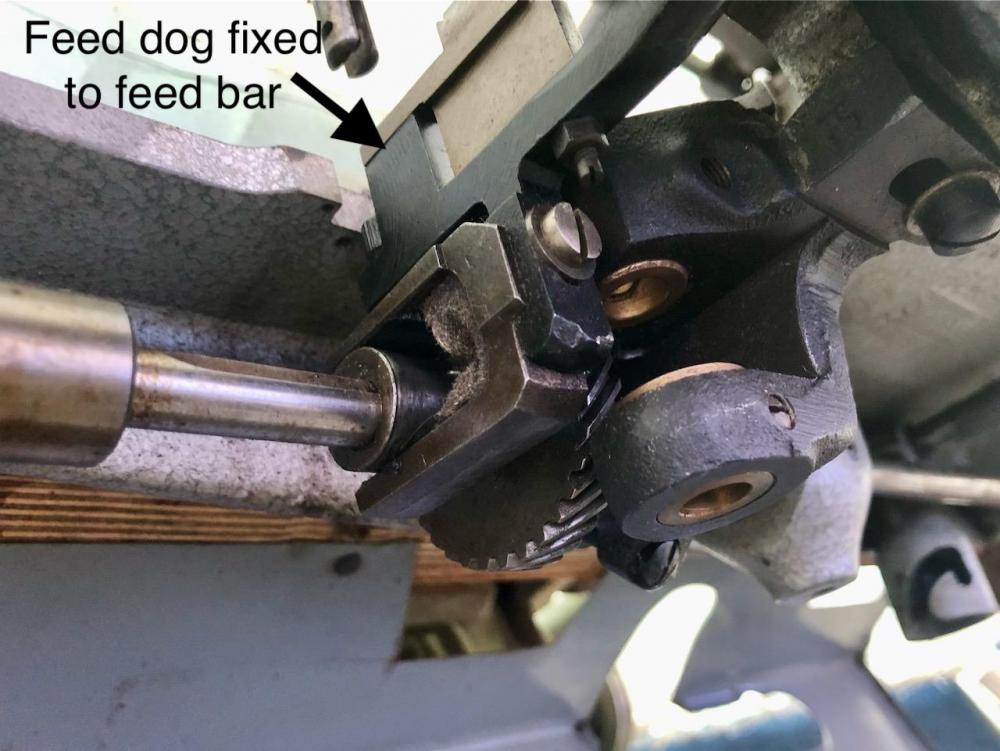

Thanks @Constabulary The top part of the hook looks OK I think, would there be a reason to replace it? A replacement through is very cheap, thanks for that! I checked for play between the fork & the cam, and there is hardly any play. I can't get a sheet of paper between the fork & the cam, so I guess this is some good news? The fork has the oil soaked felt to keep the two lubricated. As for the feed dog, I used an incorrect description above, I meant to say the feed dog is secured to the feed bar, not the feed fork. I can see the bar is secured with the feed bar hinge screw, one side of which is just accessible with a slotted head, but the other side (hexagonal nut head) is inaccessible. I tried to unscrew the hinge screw, without success so far. But now I see another problem... There isn't enough room to remove the hinge screw, either to the left or the right side, because it will hit the base casting before it can be removed given its length The only way I can see to remove the feed bar, is to remove the feed driving rock shaft first. Has anyone removed one of these feed bars? Thanks again