-

Posts

8 -

Joined

-

Last visited

Profile Information

-

Location

Miami, Florida USA

-

Interests

Computers

LW Info

-

Leatherwork Specialty

Novice

-

Interested in learning about

Basics

-

How did you find leatherworker.net?

Google

JoelM's Achievements

New Member (1/4)

-

- 18 replies

-

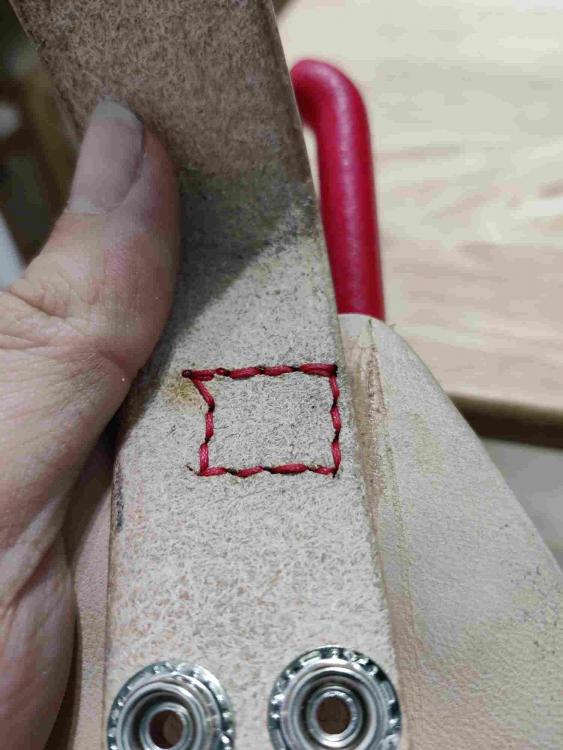

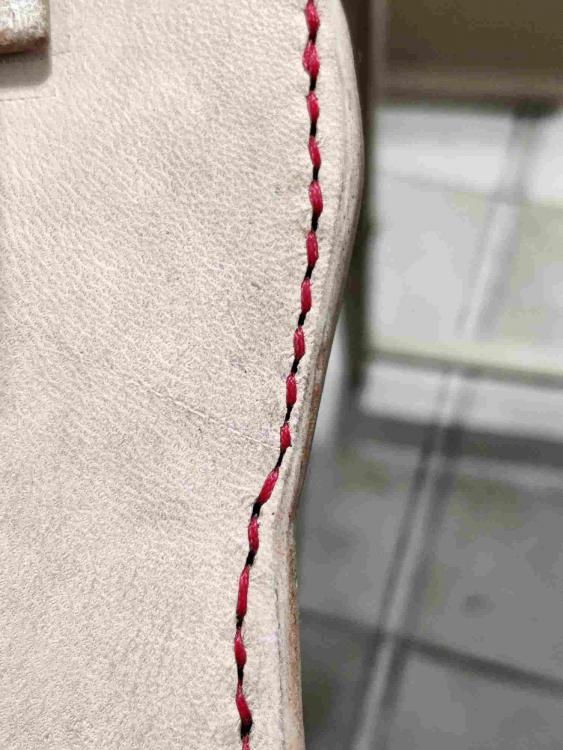

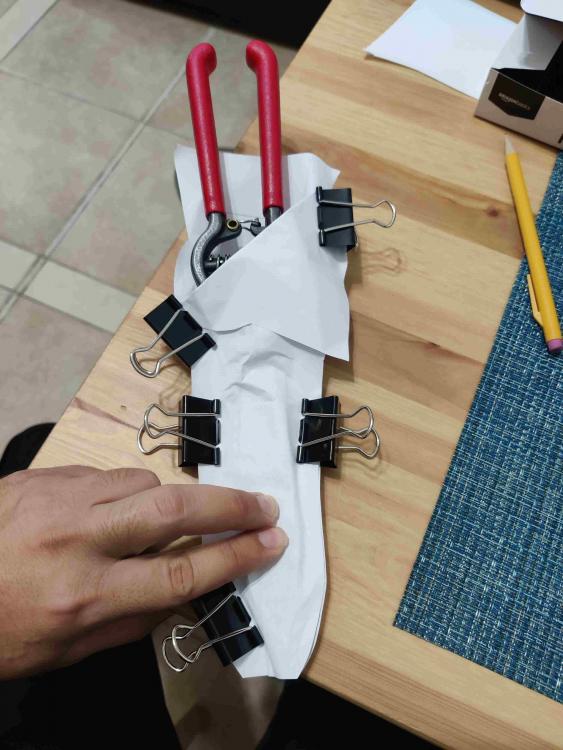

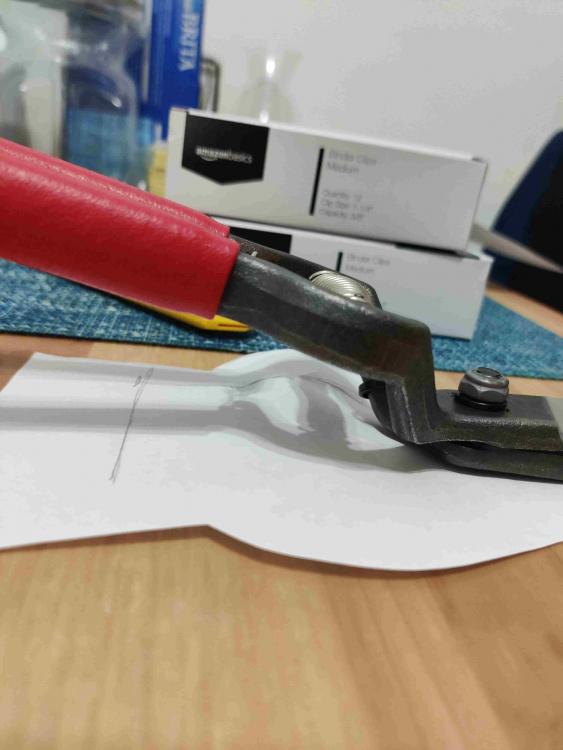

Hello everyone! I finished my project tonight. Let me share the project with you. The images are very compressed in order to get them uploaded on one post that's why the color looks wonky and patchy. I received the belly from weaver on Thursday. The first think I did was to cut out the template I had made with cardboard. Then I drew a much thicker version to account for the molding of the handles. I had no idea if it was going to work but I figured I had a whole belly to try again with so just went with my gut feeling. I went ahead and wrapped the scissors and started to mold the tool by hand and with a slicker. I didn't staple it down or anything. Just kept molding it and eventually it kept it shape over night. This is what I ended up with on Friday morning. I wish I would have wrapped the scissors better. Some water got in through the tip and now I have surface rust stains the scissors. I'm not sure if the reason I got the nipples on my caps is because I hit it too hard or if the setters are cheap. I used Realeather Crafts Snap Setter Kit, 24-Litter, Nickel from Amazon. Would love to hear feed back on this since I prefer nice round caps. I'm happy that I wet molding the scissors. It's not very pretty but sure holds well! This was not how I originally wanted to put the strap but it was getting late and I was excited that the project was coming along and I stitched the two halves together before putting in the straps I wanted. Opps.. Also I didn't let the white glue dry all the way which caused the strap to move while punching the holes. I'm going to lay down some more stitching on this area since this is probably where most wear is going to be at. Also got a bit too close to the edge on one side.. Over all I'm happy with my sheath. It's not very good looking but it's mine.

- 18 replies

-

What weight would be good for this project? I was thinking 6-7 oz leather, the Weaver Leather Supply has a belly strip for 20 bucks.

- 18 replies

-

Didn't know Kydex existed. Looks interesting but for this project I think I'm going to stick to leather since I have a few hours of research and a few more of day dreaming of this project. haha Thanks for the share, Kydex might be a good fit for a machete sheath with a leather strap or something like that.

- 18 replies

-

For this project, weight and comfort is defiantly high on priorities. I cut laws with my father-in-law in South Florida (it's really hot at humid) for about eight hours and I'll have this strapped to my belt for a few hours at a time if not the whole time. I'm aiming for something light and also something that will avoid getting snagged on branches when I use a line trimmer. I'm exploring the idea of using a strap that wraps around between the handles and snaps to the body OR a flap that has the contours of the handles so to keep dirt from collecting inside of the wide mouthed holster... Leaving a small opening at the bottom would probably have the same effect as the flap since dirt would fall out the bottom but.... I'm a sucker for over designing things just for the fun of it. lol

- 18 replies

-

Soon I'll be buying everything I'll need for the project. I'll be back before I buy everything to make sure I'm not missing or getting the wrong things.

- 18 replies

-

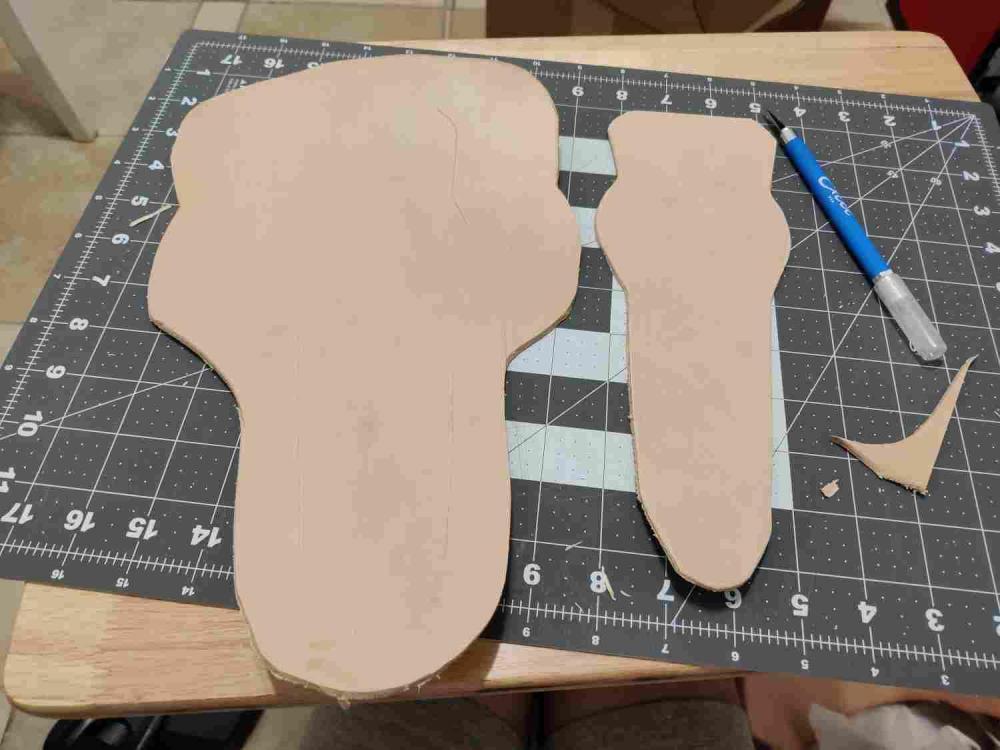

I'm not sure if I understand. Do you mean have the handles slightly angled forward towards my navel? edit: I cut a simple design for the top of the hostler that I plan on wet molding. Would something like this work or is would this cause some kind of problem down the road?

- 18 replies

-

Hello everyone! I have come for advice. I have never worked with leather before and started looking into leather craft when I bought a grass shear (The Corona GS 6750) but did not come with a sheath/hostler, making it next to useless for me. I have watched a few hours of Youtube videos of folks designing templates and wet forming. I took a crack at drawing a design for a belt hostler that I would like to make for my shears. My question: The shears won't sit flat in the holster due to an angle between the cutting end and the handles. Is there a way I can make a better fit when I wet mold? Also, any tips/tricks for building a belt holster for a tool with this kind of shape would be greatly appreciated.

- 18 replies