sportycliff

-

Content Count

30 -

Joined

-

Last visited

Posts posted by sportycliff

-

-

Thanks,

Still looking.

Converting to 60mm didn't work.

Funny, as many of these things that are out there, you'd think ebay and Amazon would be loaded with replacement belts.

-

Good morning,

Does anyone know where I can get sanding drums/belts/sleeves for the cheap Chinese sander/burnisher machines?

Approx 2 3/8" diameter x 2" wide?

I've searched ebay/Amazon/search engine and can't find any other than Tandy, and they're priced out of sight.

I'd hate to have them made if someone is already carrying them in multiple grits.

TIA

Cliff

-

6 minutes ago, CowboyBob said:16x2

Thanks!!

-

The leather point equivalent to these needles?

-

On 2/13/2023 at 1:16 PM, CowboyBob said:Ok ,Is there any play in the gears that drive the hook? And have you tried timing it @ 2.2 rise?

I'll check for play tomorrow. I timed it with 2.5 (factory spec)?

Packed up and heading to the tech early tomorrow, bit of a ride, but hopefully it'll get straightened out...

-

8 hours ago, CowboyBob said:Ok ,Is there any play in the gears that drive the hook? And have you tried timing it @ 2.2 rise?

I'll check for play tomorrow. I timed it with 2.5 (factory spec)?

-

Just now, CowboyBob said:You might want to check the small finger that keeps the inside of the bobbincase from turning,if it is set too close to the hook it can pinch the thread & prevent it from passing through.Run the machine by hand & watch it as the thread passes through this part.

checked it and it'll run 207 easily and cleanly.

-

1 minute ago, CowboyBob said:Try size #92,138 might be too large for this machine.

Same problem with #92...

-

Found a repair shop only a couple of hours away, going in next Monday.

-

On 2/4/2023 at 7:29 AM, sportycliff said:I never considered that the closer the hook to the needle the tighter the notch clearance as well, I'll play with the gap some more...Thanks

No difference.

-

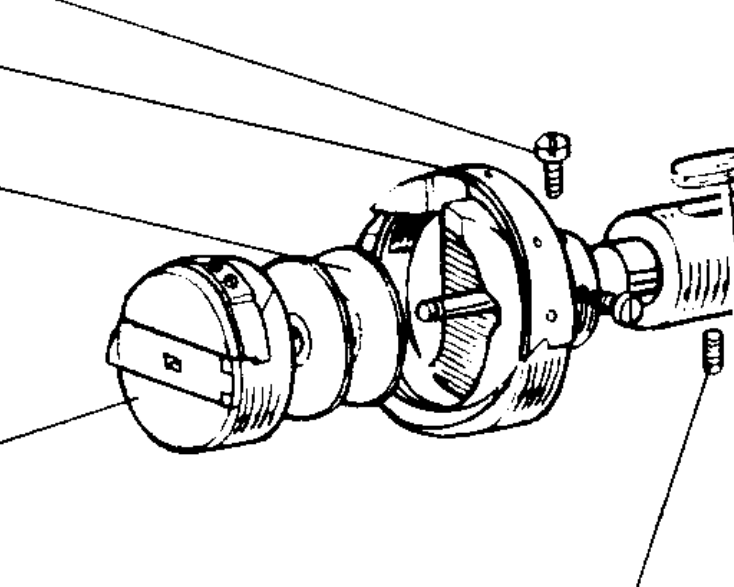

On 2/4/2023 at 12:22 PM, DonInReno said:I’d suggest taking off the end cap so you can watch the thread as it goes through a stitch - modifying something that doesn’t need to be modified is just guessing.

Everything seems perfect. Can easily slide 207 through the notch no hangups anywhere, tried multiple gap hook/needle gap and timing changes, it does seem that sewing speed changes quality from maybe ok on some stitches to loops on others, no consistency at all. I'm down to size 92 and still having the same issues. I don't think it's a tension issue any longer, this machine (by feel) is running MUCH higher tension on 92 than my other is running with 138 or 207 and still loops on the bottom, with shitty stitches all the way around. I'm waiting on slow boat for another feed dog, but now I'm playings part replacer instead of proper diagnosing and doing it right. #Frustration

-

2 hours ago, kgg said:I would keep it simple with a mechanical connection (wire / wire rope or chain) to a foot pedal and do the re-routing. The two problems I see with the linear solenoids are you have to spec the length of stroke and it is an all or nothing movement where with power on you get full stroke. If you need to turn the item like when doing a 90 degree turn you need to be able to lift the presser foot up slightly so you are probably going to have to force the presser foot level up by hand.

A picture of your setup may help to get some suggestions.

kgg

There would have to be a pulley attached alongside the existing chain hole (I'd use small cable for flexibility)

I'd also have to fab up a couple of smaller pedals as there is not enough room even for a single width pedal.

All doable of course, but a solenoid and electric momentary pedal would be easier, you do make a point about the full stroke, but isn't that how the pneumatic setups work as well? I will look into pulleys as well.

-

Mitsubishi CU-865 22

Originally (before I owned) had pneumatic lift. Was removed prior to my ownership.

I wouldn't want to deal with a compressor, and mechanical is a no go without some type of pulley re-routing due to the install of a box type speed reducer.

With the original Mitsu servo and controller, there is little room down there.

I'ver been researching 120v high force linear solenoids such as this... but figure I'd ask if anyone had gone this route or any other thoughts?

-

On 2/4/2023 at 4:28 AM, Constabulary said:maybe its just the hook that is a bit close to the needle so the gap between hook notch and position finger is too tight. You can move the hook a tiny bit (maybe 0.5mm or so) to the right (if not already flush with the machine arm) by loosening the 2 or 3 set screws on the hook body. Better check the needle hook timing after doing this.

I never considered that the closer the hook to the needle the tighter the notch clearance as well, I'll play with the gap some more...Thanks

-

9 hours ago, DonInReno said:I’m out of ideas - it appears that there is roughly enough top tension to mostly pull the knot up, but that lower thread looks crazy and appears to have varying amounts of tension. I’d guess it’s partially whatever brand and type of thread and partially something underneath it’s hanging up on giving the inconsistent bottom tension.

The finger that keeps the bobbin case in alignment has to have enough clearance for thicker thread to pass around easily. There is no bobbin case opener to adjust, but clearance is adjusted with careful metal removal and polishing.

If this machine was made to only sew thinner thread, in addition to a tight area at the bobbin alignment notch, there may also be resistance from a tight spot somewhere else around the bobbin case that would have to be clearanced.

Thats about all I’ve got.

I've tried two different types of bonded nylon. Both run fine on my other machine.

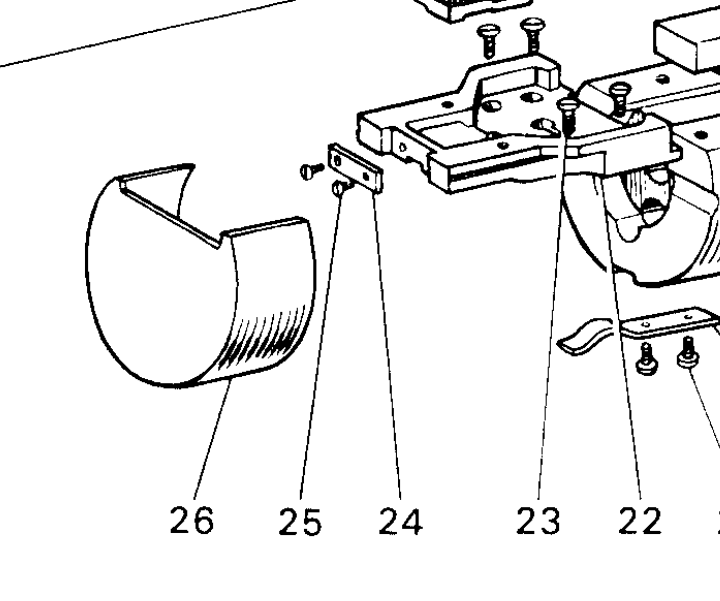

Number 24 has a finger on the bottom side which fits a notch in the hook assembly

which stops the center section of the hook from spinning, is that what you mean?

I don't mind a little mod work, just want to mod the correct items.

9 hours ago, DonInReno said:

9 hours ago, DonInReno said: -

On 1/31/2023 at 12:27 PM, kgg said:If I'm not mistaken this machine has the same capabilities as the PFAFF 335 and similar clone machines. Most of the 335 machines are really only capable of sewing with V92.

It shares the same bobbin case, bobbins, and looks like the same hook as my Sailrite Fabricator.

That machine has zero problems with 138, nothing is shredding, so I assume clearances are ok, I'm going to try adding a pre-tensioner.

-

6 hours ago, Burkhardt said:Now you're sewing on a single piece of leather that might not be thick enough to hide the knot. Another thing I see is how the top stitches have a descent stitch length but are tight on the bottom. How firm is the leather you're using? Does the leather lift at all off the arm when stitching?

I've got both feet maxed out...doesn't seem to lift at all.

57 minutes ago, Constabulary said:I still would assume you need a larger needle or a thinner bottom thread and / or try a heavier beehive spring on the tension unit. If the former owner sewed fabric then the spring may be too weak.

This is from College Sewing in the UK but you will find them on your end as well:

https://www.college-sewing.co.uk/b3114-232-000-beehive-spring-heavy-juki-genuine.html

When you haven lowered the foot on the material do the tension discs feel kinda loose or wiggly?

I'm looking into adding a pre-tensioner, I didn't realize heavier duty springs were available too, I'll look for both. Thanks.

-

Any other thoughts?

-

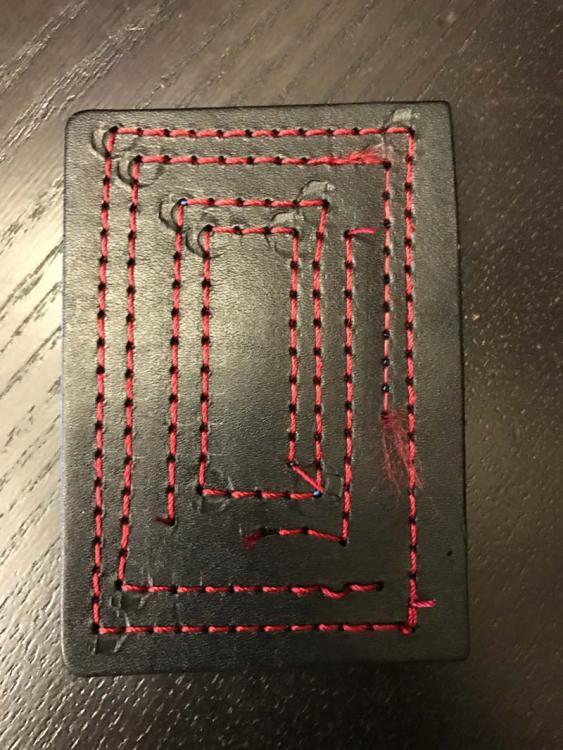

Ok, just noticed this, not sure if it's relevant.

The guy who owned this before me apparently ground the teeth down to almost nothing on the feed dog.

I just noticed it was at and/or below the surface of the plate.

That may explain the crappy stitching, but would it cause the looping? I tried maxing both foot pressures, and it doesn't change anything...

The feet on the machine are smooth, so my guess is that the only thing feeding is the needle. I tried my serrated outside foot from my other machine, maybe a lttle more consistent stitch(?) Maybe wishful thinking. I've ordered a binding set but it's smooth, and apparently the only style on ebay or amazon. Anyone know where to get a serrated dog for one of these?

-

-

17 hours ago, DonInReno said:There are definitely some skipped stitches on the bottom side, so that may be another issue.

it sounds like you’ve had one heck of a day chasing this thing around - you’re really close to getting it, so tomorrow should be a good day

Not a better day at all.

Replaced tensioning system, and adjusted

Re-timed hook to factory specs Needle bar 2.4 mm up from bottom .5 mm needle gap, 1-1.5 mm above eye

Best I can do on ONE layer of 2.4 mm veg tan...Knots on top And occasional loops on bottom, and a crappy stitch.

-

3 hours ago, Wizcrafts said:Try to cop a boo at the thread as it goes around the bobbin case and comes up to see if it is snagging on something. Also, check the hook timing to see if it is retarded and too close to the eye. If it is close, advance the timing a bit so the hook is about 1/16 inch above the eye at pickoff time. Also, make sure the hook isn't hitting the needle and that the needle easily clears the hole in the feed dog..

Q: Are you using a leather point or round point needle?

8 minutes ago, DonInReno said:Those are definitely twists in the thread or the thread is untwisting as it forms the knot - not a tension issue. Sorry to drag you through all the tension stuff - I should have asked for a picture.

What brand and type of thread is it? To be honest, if I don’t know anything about the bottom problems I’d still think your thread doesn’t look right on top - like it’s not bonded and a loose twist - not the normal dense bonded nylon we usually use. The good news is, a different spool of thread will probably solve the issue.

I’ve attached a random picture of 138 size thread - look at how twisted your top thread is compared to how it lays down flat in the pic.

While I guess anything's possible, it sews perfectly on my other machine, and on lighter bag leathers. I'll swap it out with something different first thing.

I think @wiz may be onto something with the timing. I've changed the timing twice since he posted and had worse results, and slightly better results. I'll try again tomorrow as my arthritis is telling me it's time to quit.

I also receive a new tensioner in the mail today, I'll put the timing back to where it was and try that tomorrow just to rule it out, then go back to the timing...will post back.

-

30 minutes ago, Wizcrafts said:Try to cop a boo at the thread as it goes around the bobbin case and comes up to see if it is snagging on something. Also, check the hook timing to see if it is retarded and too close to the eye. If it is close, advance the timing a bit so the hook is about 1/16 inch above the eye at pickoff time. Also, make sure the hook isn't hitting the needle and that the needle easily clears the hole in the feed dog..

Q: Are you using a leather point or round point needle?

Leatherpoint, brand new. I will chk the timing.

-

.thumb.jpg.3e64ed7cef7adfdf382a99fc5824838f.jpg)

.thumb.jpg.1ad9991c49aeb807823a70c14fdc7929.jpg)

Chinese burnisher and sander

in Suppliers

Posted · Report reply

Still looking...