-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by sportycliff

-

.thumb.jpeg.2101477021e843ad8ab0d716dd841942.jpeg)

Accurately cutting "stretchy" leather.

sportycliff replied to Shadders's topic in Leatherwork Conversation

Instead of cork backing, try using 220-400 grit adhesive backed sandpaper on your rules. Right to the edge, as long as you're slightly careful it shouldn't scratch the leather, and it will minimize stretch. I like the rotary cutters as well, but it's another tool to keep sharp. Just another option... -

I would try something like at least an 8/9 oz latigo. Latigo is one of the strongest leathers, and of course the thicker the better.

-

.thumb.jpeg.2101477021e843ad8ab0d716dd841942.jpeg)

Table Top Questions for Cylinder Arm Machines

sportycliff replied to kgg's topic in Leather Sewing Machines

Well I received my large table and swing down guide adapters for my CB4500 from @Patrick1. Damn, I'm impressed! The fit and finish of the table is perfect. I'm actually shocked that the tolerances were so good considering it's a Chinese made casting that it fits. Call that a win for Patrick and the Chinese factory. It' great with the factory round needle plate and one of Patrick's own flat narrow needle plate. (a previous purchase) The swing down guide adapters and the recommended Chinese guide are also flawless. This will be a perfect "2nd" heavy stitcher, now I have a flatbed to go with the cylinder arm. Thanks Patrick! -

Great job! Thanks for the story, my timing finding it was perfect. I got to read and see it all at once.

-

.thumb.jpeg.2101477021e843ad8ab0d716dd841942.jpeg)

Table Top Questions for Cylinder Arm Machines

sportycliff replied to kgg's topic in Leather Sewing Machines

Can't wait until this is available!! I'm in! -

Still looking...

-

Thanks, Still looking. Converting to 60mm didn't work. Funny, as many of these things that are out there, you'd think ebay and Amazon would be loaded with replacement belts.

-

Good morning, Does anyone know where I can get sanding drums/belts/sleeves for the cheap Chinese sander/burnisher machines? Approx 2 3/8" diameter x 2" wide? I've searched ebay/Amazon/search engine and can't find any other than Tandy, and they're priced out of sight. I'd hate to have them made if someone is already carrying them in multiple grits. TIA Cliff

-

Thanks!!

-

-

I'll check for play tomorrow. I timed it with 2.5 (factory spec)? Packed up and heading to the tech early tomorrow, bit of a ride, but hopefully it'll get straightened out...

-

I'll check for play tomorrow. I timed it with 2.5 (factory spec)?

-

checked it and it'll run 207 easily and cleanly.

-

Same problem with #92...

-

Found a repair shop only a couple of hours away, going in next Monday.

-

No difference.

-

Everything seems perfect. Can easily slide 207 through the notch no hangups anywhere, tried multiple gap hook/needle gap and timing changes, it does seem that sewing speed changes quality from maybe ok on some stitches to loops on others, no consistency at all. I'm down to size 92 and still having the same issues. I don't think it's a tension issue any longer, this machine (by feel) is running MUCH higher tension on 92 than my other is running with 138 or 207 and still loops on the bottom, with shitty stitches all the way around. I'm waiting on slow boat for another feed dog, but now I'm playings part replacer instead of proper diagnosing and doing it right. #Frustration

-

.thumb.jpeg.2101477021e843ad8ab0d716dd841942.jpeg)

Foot lift Actuator...electric, pneumatic, mechanical?

sportycliff replied to sportycliff's topic in Leather Sewing Machines

There would have to be a pulley attached alongside the existing chain hole (I'd use small cable for flexibility) I'd also have to fab up a couple of smaller pedals as there is not enough room even for a single width pedal. All doable of course, but a solenoid and electric momentary pedal would be easier, you do make a point about the full stroke, but isn't that how the pneumatic setups work as well? I will look into pulleys as well. -

Mitsubishi CU-865 22 Originally (before I owned) had pneumatic lift. Was removed prior to my ownership. I wouldn't want to deal with a compressor, and mechanical is a no go without some type of pulley re-routing due to the install of a box type speed reducer. With the original Mitsu servo and controller, there is little room down there. I'ver been researching 120v high force linear solenoids such as this... but figure I'd ask if anyone had gone this route or any other thoughts?

-

I never considered that the closer the hook to the needle the tighter the notch clearance as well, I'll play with the gap some more...Thanks

-

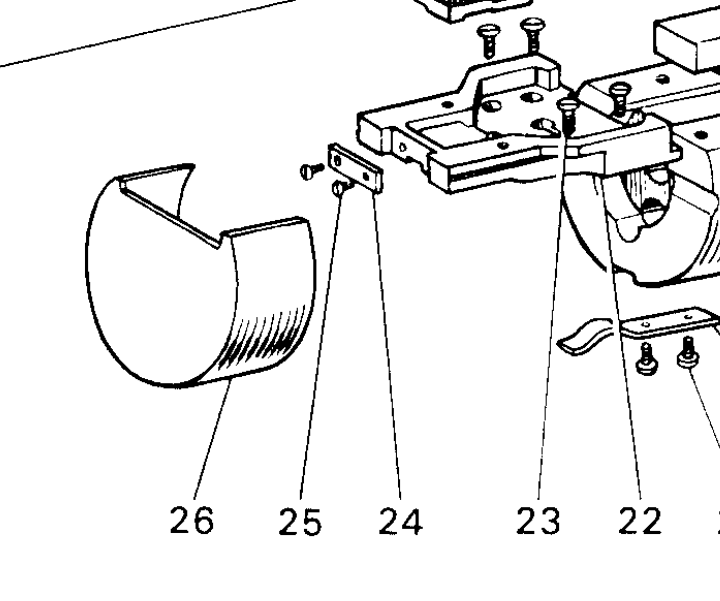

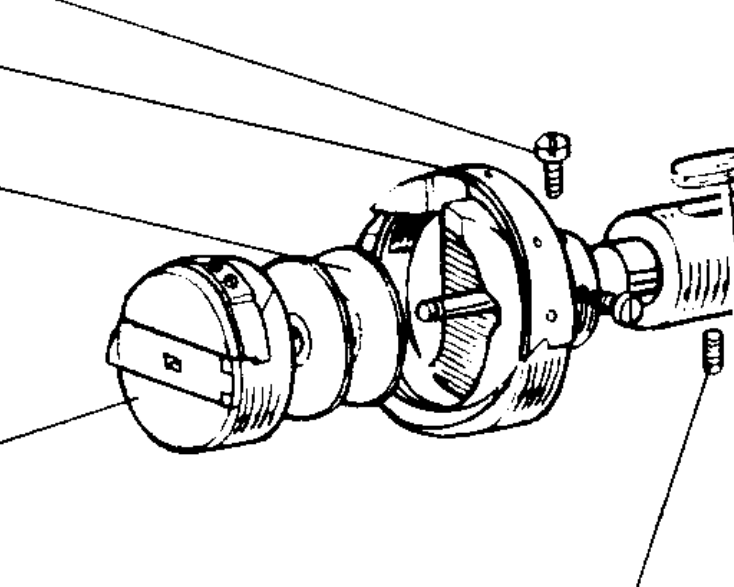

I've tried two different types of bonded nylon. Both run fine on my other machine. Number 24 has a finger on the bottom side which fits a notch in the hook assembly which stops the center section of the hook from spinning, is that what you mean? I don't mind a little mod work, just want to mod the correct items.

-

-

I've got both feet maxed out...doesn't seem to lift at all. I'm looking into adding a pre-tensioner, I didn't realize heavier duty springs were available too, I'll look for both. Thanks.

-

Any other thoughts?

.thumb.jpeg.e8e1181fed283d255799825a11dd3c70.jpeg)

.thumb.jpeg.b2590c818917d3ad03d7e4d4933f191a.jpeg)

.thumb.jpeg.e5f4d7799166b8661770badbe430ded7.jpeg)