Chris623

Members-

Posts

243 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chris623

-

I imagine it does a pretty good job. The one I was looking at was the 3790-00. I think it would do a good job..............but even at $200 on sale I can't afford it. I saw enough of it I feel reasonably comfortable that I can make one.

-

I have violin maker's planes...........................used to be a repairman. But not so sure they would give me the precision thickness's I'd need. I'm going to look into making a splitter...............or an attachment to put on my 2x72 grinder to "surface" the leather down to a desired thickness.

-

Just got back from Tandy. Went to Tandy to look at their #3790-00 High Tech Leather Splitter to test it out. What a waste of time. Looked like a good piece of equipment, but the clerk showing it to me took my 8-9 oz leather and tried to cut it down to 2-3 oz in one cut. Of course, it wouldn't work. I tried, politely, to get him to take it down about a 1/16" at a time but he huffily said "That would take far too long!" After he walked away, I decided to try it myself and he came up and said "I told you it would take too much time" and took my piece out of the cutter and handed it to me. I walked out of the store. If I had the $200 to spare, I'd buy their splitter. Well made and looks as if it would do a nice job. I'll make my own. I've found a good one to copy on Youtube. I just don't get the "I know it all" attitude of some people.

-

Would be nice to have either one of those tools, fredk. But I'm wanting it to occasionally adjust the thickness of a welt for a sheath. May end up having to make my own splitter.

-

How can I skive long strips of Veg-Tan uniformly? I've never used any kind of "fixed" tool, so I'm not quite convinced how well it would go.

-

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Sorry I'm just now responding, blueduck. We lost power last Tuesday morning due to the severe ice storm that hit Norman, OK. Just got it back on. Tell you what, 4 days without heat, lights and water make a feller worry a mite about our future if some nefarious Country decides to hit us with am EMP! Thank you for your response. Don't know why I didn't think about the multiple layer "thing" for the thread computer. Makes sense. Thanks. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Oh, I know what a "taco" or folded sheath is. I thought you were suggesting the next time I try and make a stacked sheath to think "taco". I'm sure I'll make plenty of folded sheaths in the future. I just decided to make the stacked sheath for my first one because a folded sheath wasn't a suitable choice for the Buck 119. I like folded sheaths. They make logical sense to me both aesthetically and mechanically. I'm making a knife as my own EDC at the moment that I think might be a good choice for a folded sheath...........or maybe pancake sheath. Haven't decided which. Anyway, battlemunky, thanks for the splain'n. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Thanks. (says the sponge!) You're going to have to 'splain that one, battlemunky. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Ha-ha. That's exactly what my shoe repairman friend said when I mentioned I wanted to dye the edges of my sheath Black. Due to not knowing how to make a sheath like this, I ended up with 4 layers between the front and back faces. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

So you sand your edges and dye them. (or not) Then you rub glycerine bar on them and slick with a stick or heavy canvas? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Okay, thanks. Bar it is. I saw Gonzales using one of those in a video I think. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

I originally had Brown Fiebing's Edge Kote on it. By "paint" do you mean like their Black Edge Kote? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

battlemunky, did you mean liquid glycerin saddle soap, or the bar type glycerine saddle soap? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Now that's a neat trick. Felt dye brush. Would never have thought of that............but it makes sense. So many little tricks to learn. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Stopped by my buddies shop, (local shoe repair) and even though I bought some Pro Black Dye, he recommended I leave it as is. Said he'd be very afraid it would bleed into the dye of the face or back of the sheath. Hmmmmmm. As a newbie, he has me concerned. Should I be? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Thanks, battlemunky. I've got saddle soap, Fiebings Black dye and canvas on my shopping list for today after I finish working out at the gym. I used some denim material yesterday and it did a pretty decent job on the slicking. Since I've already slicked the edges, should I re-sand so the dye will penetrate? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Well, if it makes any difference, I used very little Mink Oil. But thanks for the Fiebing's dye recommendation. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

"it" being the oil, or "it" being the Black Sharpie? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

I have a question: I just put "slick job" on the edges of the sheath. I dyed the edges the same color I did the sheath. Then I applied water and slicked to a shine. I didn't have any saddle soap, so when I lightly Mink Oiled the sheath, I did the same to the edges. I originally wanted to dye the edges Black...............and would still like to if I've not gone too far to do that. I saw a fellow on Youtube actually coat the edges of a holster with Black, permanent Sharpie. Would that work now that I've oiled the sheath, or would it not stick? -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Thanks for the accolades, battlemunky. I've been an artist all my life in one venue or another. I can't live if I don't create. Just who I am. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

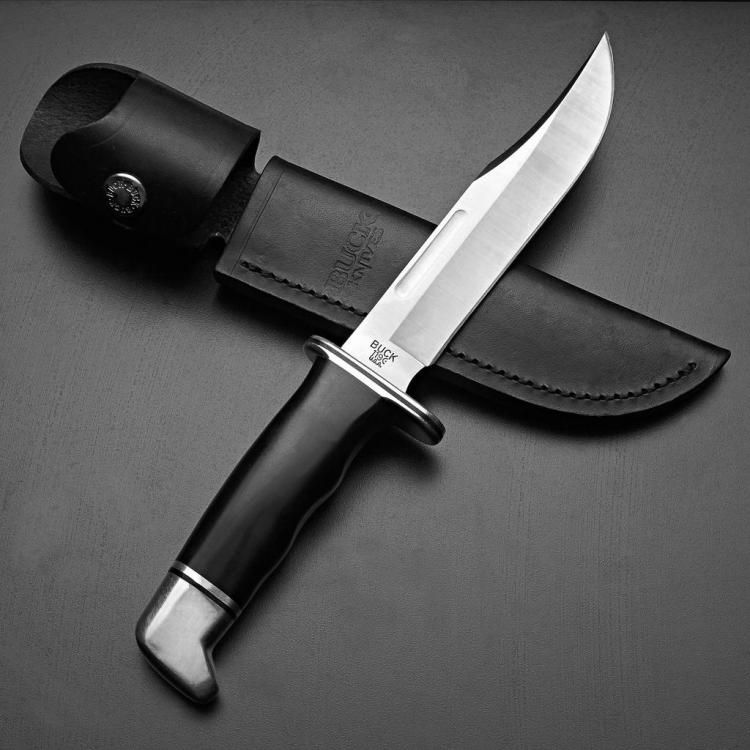

Oh, I didn't make the knife..................it's just a Buck 119. Had mentioned that in the thread and figured everyone had seen one. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

WHEW! Glad I didn't post larger pics! Thanks, battlemunky. Like I said, I'm a perfectionist.......literally. I'm a retired custom furniture builder.............probably one of the few in the country who used a vernier dial caliper more than a tape measure. ( www.chrischristenberry.com ) I'm super critical about anything I make with my hands. I guarantee you, if you held that sheath in your hands you'd have much to speak about in negative terms.........as have I. I'm going to work real hard to make the next sheath one I'll be truly proud to show you guys. There are so many extremely talented leather workers here on this site. I'm just trying to absorb all the information I can from all of you. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Alrighty then, here ya go. I still need to put Black Edge Kote or something similar on the edges. Think it will look a lot better with the Black handled Buck. \ I already know it's not great, but I'd consider it "not bad" for my first attempt. I need to buy (ugh!) some more stamps. I'll sure do a lot of things a lot differently with the next sheath. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Okay. Got this durned thing all stitched up. When I finished, I noticed some of the stitching is the color of the stitching as it's wound on the roll. In other places it's dark...........as if it's dirty. (I liked that..........it matched the color of the sheath) So I tried to clean the stitching with rubbing alcohol. It took some of my Top Kote and antiquing off. So I tried to rub more of the antiquing off so it would be more uniform. While I was at it, I removed the brown Edge Kote I didn't really care for. I think I'd rather have black. Put on a new layer of Pro Resist as a top layer. Will let it dry and do a second coat. Am I happy with my sheath? Hard to say. I'm a gal-darned perfectionist, so from that standpoint I'm totally disappointed. However, I'll seldom carry this knife and no-one but "me-I-my-picky-self" will ever see it, so in this case it'll do. I learned a ton making this sheath. First off I learned I'll never learn! By that I mean I always have to start with a project far beyond my experience. Most of the time I can get away with it..........but this time I didn't. Second, I think it will be a long, long time before I tackle another stacked sheath. (WHEW!) It was a fun project and I thank all of you who contributed input to help me through the process. I'll do my best to absorb all that was shared and apply it toward the next one. I'll post a pic tomorrow after the second coat of Pro Resist dries. -

I'm confused about the purpose of some of these products

Chris623 replied to Chris623's topic in Getting Started

Wish one of you with more experience were sitting beside me while I'm stitching this! My first stitching. What can I say? Well, it'll hold, for sure! Found a neat little app to judge the length of thread I needed to start with from CanadianLeatherCraft.org. The app determined 83". I was concerned about being too short right at the end so I cut it at 90". All I was able to do with that length of thread was the spine side of the sheath. There wasn't any place in the app to enter how thick the sheath is. They had "leather thickness" in ounces, but that couldn't figure how thick my sheath is at the knife's guard vs how much thinner it is at that tip. I couldn't get my stitches to do that fancy diagonal slash. My holes where punched with a diagonal iron. I punched the first layer but had to drill through the others with a 1/16" drill bit. That might have been my problem. Sure have a list of "What to do and what not to do next time" things to remember!!! I'm not worried about the stitching. I picked a thread that so closely matches the color of the sheath, it's hard to see even when I hold it in my hand. No-one looking at it from any distance at all is going to notice any anomaly. This is fun. Uphill journey, but I'll git'er eventually.