hugocrafts

Members-

Posts

18 -

Joined

-

Last visited

Contact Methods

-

Website URL

/

Profile Information

-

Location

Oxford, Connecticut, USA

-

Interests

Leather Work, Rebuilding Sewing Machines, Knive Making

LW Info

-

How did you find leatherworker.net?

Internet

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

hugocrafts's Achievements

Member (2/4)

-

Pfaff 145/545 owners – Little help needed

hugocrafts replied to hugocrafts's topic in Leather Sewing Machines

Gotcha. In that case it seems like I didn't have the second screw in a first place. I'll get them both now. Thanks for that and have a nice day. -

Pfaff 145/545 owners – Little help needed

hugocrafts replied to hugocrafts's topic in Leather Sewing Machines

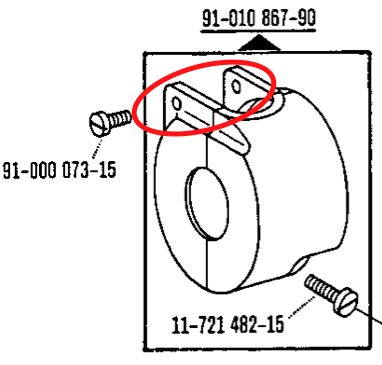

Indeed It says M3.5 x 9mm. Hm...but that's weird because I was expecting to be a little longer maybe, because there's a 2 holes on the cover (see photo) and I thought the screw should go into both holes because If it's indeed only 9 mm long then it should be screwed only into 1 hole on the hook gear cover leaving the second empty? Is someone willing to check this? -

Hello. So, recently I lost this little screw (see on the photo below) that holds the bevel gears cover. I was wondering If any of you guys – owners of Pfaff 545 or Pfaff 145 perhaps would like to take a measure of the length of this screw hopefully? I tried to search it in the Pfaff parts manual that I got but I couldn't find the dimensions. Thanks in advance. Best regards

-

PFAFF - size of balls for bearing

hugocrafts replied to DanishMan's topic in Leather Sewing Machines

Thanks for the reply, @DanishMan. My goal is to replace just the presser bar without having to disassemble other parts If possible. So, I was thinking to pull the old presser bar from the above, If that's possible. Thanks for the warning and letting me know about the little bearing balls, I'll keep that in mind when I'll be doing the procedure. Maybe I'll try to put some grease If possible to keep the balls from jumping off and a small bar with the same thickness in diameter in order to hold them like you suggested. If you have any other advice on that, don't hesitate to share it. Best regards, Hugo -

PFAFF - size of balls for bearing

hugocrafts replied to DanishMan's topic in Leather Sewing Machines

Hello, @DanishMan Can you tell me where this ball bearing part (91-019 657-05) goes? Is it housed inside that bushing part 91-019 656-05? I have to change my presser bar. I still haven't disassembled it yet, but now as it is I can't see this ball bearing part. Do you have any photos of this ball bearing 91-019 657-05? Perhaps when you were installing the little balls for the bearing? Best Regards, Hugo -

Timing Position for Pfaff 545 H3?

hugocrafts replied to hugocrafts's topic in Leather Sewing Machines

Hi, @Johnny. Thanks for the help. You have the exact model 545 with H3 lift? -

Hey, everyone Does any of you guys know what is the timing position for Pfaff 545 H3?

-

Hi, @Uwe. Thanks for the videos. Sorry, I've been off for a while due this pandemic chaos and now, I saw the reply. What is not clear to me, If inside there are 2 springs as shown in the Pfaff diagrams - 1 smaller and 1 larger? On my Pfaff, there's only 1 spring and when I pulled it, it broke in my hands, but the other one was missing?! If there are indeed 2 springs, how they should be sitting inside? The smaller one inside the bigger one or? And btw, now I noticed another problem If I could define it as such. I think the presser bar on my Pfaff is not genuine. I know you are a Pfaff guru, so please check it out the topic below and If you could be able to advise me on what to do, I'll be very thankful. Here's the link: https://leatherworker.net/forum/topic/92953-pfaff-545-cant-fit-a-new-presser-foot-my-presser-bar-probably-not-genuine/

-

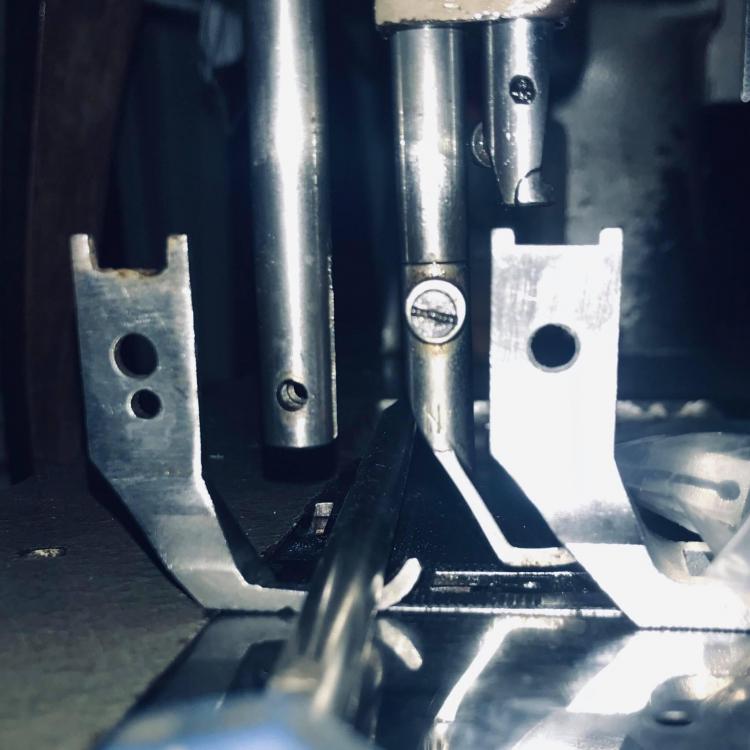

Hello, friends So, recently I bought a new set of walking foot for my Pfaff 545 (right side on the photo). However when I tried to fit the presser foot, I couldn't change it. Then I noticed on the existing old presser foot (left on the photo) there's a small hole drilled under the bigger one (probably the bigger one is the original hole) and also the old presser foot is a little thinner than the new one. So, I guess my presser bar is not OEM or genuine for my 545 model, right? Seems like that, but the problem is I cannot find a presser bar spare part for the 545 models. I only found presser bar for 1245 but I guess they are very different. I was thinking to remove the existing presser bar and maybe drill and tap another hole above it because by using it like this as it is, I'm only limited to use just this one presser foot. What do you think I should do guys?

-

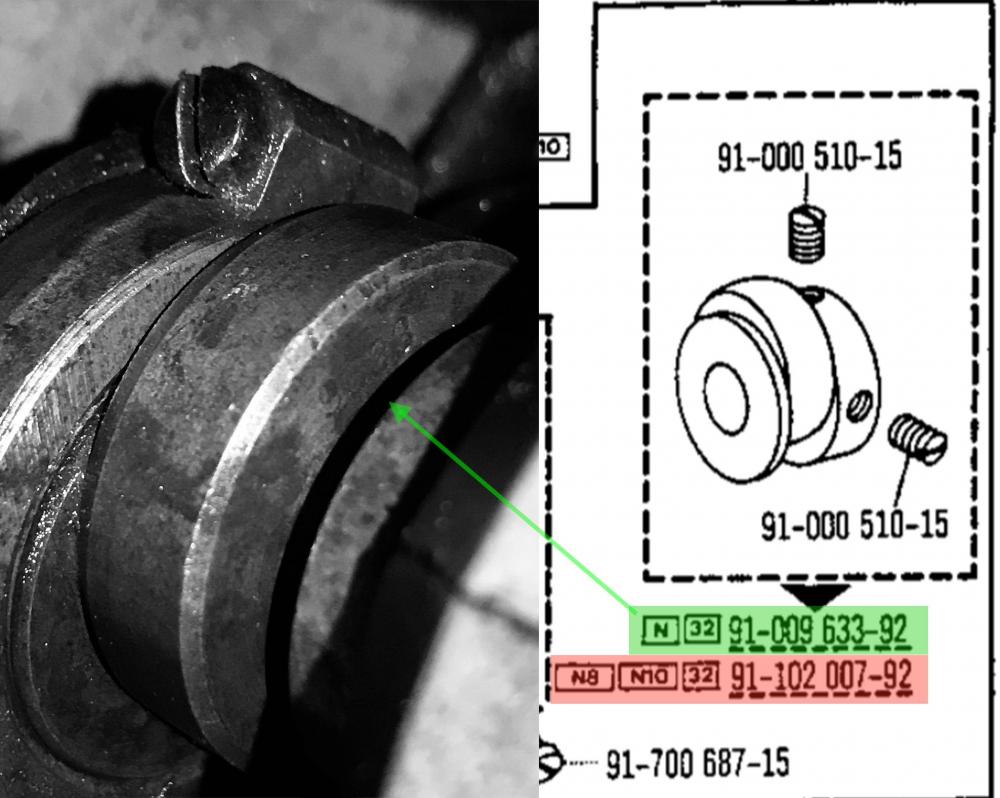

SOLVED! Regarding the maximum stitch length. Brass plate says N8, however I found out that the eccentric wheel has a part no. 91-009 633-92 equivalent to N (which stands for a maximum stitch length of 6 mm) or 9633 for short as it's stamped on the part, instead of part no. 91-102 007-92 or 2007 stamped on that eccentric wheel which is equivalent to N8. So, that's a quick update If anyone in the future will ever experience something like this.

-

@Uwe Back to the other problem. I'm having this other problem with the tension release on this 545. The tension release rod was missing and also a little spring on the back is missing as well. I fabricated the tension release rod that goes from the front through the back of the machine which I found out to be 60.5 mm in some of the Pfaff part books, but It does not work yet, because 1 of the 2 springs on the back is still missing. Now, here's the thing, the problem is, I don't know the exact position of where that little spring sits. I only know the location of the second spring because it's pretty obvious. Here's the mechanism on the back. What do you think @Uwe ?

-

@Uwe Yes. Let's get to Pfaff 545. Regarding the Pfaff, mostly my girlfriend is going to use it generally for re-upholstering some sofa cushions. Probably like 5-6 layers of vinyl or leather, 1 mm each thick or something like that. I guess the lack of the letter 'P' i.e. the '4 motion feed' mechanism won't be that noticeable for this kind of purpose without shifting material as I understood you well in your previous post, right?

-

@Uwe, Well, I'm keeping this Pfaff, but I'm getting another one preferably with reverse, so later on, I could sell one If it does not suit my needs anyway. In that case, Consew 225 is out of the game because it does not have reverse. So, I guess the choice will be made from the class 111G beause 111W seemed they didn't have reverse too? What's the difference between 111W and 111G classes anyway? Are the 111G machines an updated version of 111W with just a reverse lever and the rest is basically the same as 111W? Are their parts interchangeable including the Consew? They seem all the same to me with that bump and in many other aspects, I don't know If there's any difference internally? Also, what is the difference between the models after the letters G or W such as 155 and 156? Is it the bobbin size only? @Wizcrafts Thanks for the feedback. Which one suits the best in the 111G class? 155, 156 or?

-

@Uwe, I just checked again as you suggested for the correct needle position for no movement i.e. between the BDC and the hook timing position and yes, the needle still moves, I measured this movement of the needle dog and It moves about 2 mm. So, If so far the maximum stitch length was 6 mm, I guess this tiny movement of the needle of about 2 mm is that lost maximum stitch length, If I guess right? So, I'll have to play with the eccentric to make it just right. Do you perhaps have a video on how to adjust the feed driving eccentric on some of the Pfaff models? Looking at the photo you attached, yep, that connecting rod on the left is missing on my model. You mentioned also this before that the letter 'P' was missing on this subclass. Now, I'm wondering, how that's gonna affect the performance on this machine? I mean, is the difference so noticeable between CLMN and CPLMN? Will it shift the material badly? And, If It's that noticeable, then maybe I could get another one, I remember the seller also had a Consew 225 and Singers from the 111W and 111G class. Do these (Consew 225, Singers 111W, 111G) have a '4 motion feed' and perform better than this one that I already bought?

-

@Uwe, I think I did not read carefully what you pointed me with your last post so I answered about the position of the needle at BDC instead of the hook in hook-timing position. And If that's the case, then, thanks to you, it seems I found the culprit. When the hook is in hook-timing position moving the reverse lever up IT DOES move the needle in my case. Here below is a close-up video of the situation. Please confirm for sure If that's the main cause, and advise on what steps should I take to remedy this situation, Uwe? My best regards, Hugo