-

Content Count

19 -

Joined

-

Last visited

Posts posted by benfanman

-

-

Hey there,

So, I don't know about you all, but I can only make so many wallets and cardholders before it gets stale. I was just wondering what folks on here have as their top three leather project ideas that they like to make. Would be very interested in possibly making some of the suggestions (especially if you have a pattern handy)!

-

11 hours ago, LatigoAmigo said:I don't use veg tan, only chrome tan and latigo leathers (along with a laser cutter). The reason I selected Hide House's California Latigo for these bags is because the temper is very firm, unlike most latigos, and because the flesh side requires no finishing so I didn't have to line the bags.

Interesting! I'll have to look into the difference between California Latigo and other latigo leathers. Thanks for the information! Do you have any tips for working with latigo? Do you need to apply any conditioner or anything after the bag is finished, or is it pretty much ready to go when you're done? I'm guessing that not all leather suppliers finish the flesh sides of their latigo leathers?

-

On 3/11/2022 at 2:13 PM, stelmackr said:Google says:

Wikipedia says:

Thanks for this, but there was a reason I chose to post on the forum. The information out there isn't quite specific enough to makers' experiences.

7 hours ago, LatigoAmigo said:I have worked with latigo for quite a few years. It comes in many forms, with some hides very supple and others very firm. These days I buy mine from The Hide House in Napa, CA, but have made purchases of latigo from Maverick Leather in Bend, OR.

The Tannery Row has offers this description of latigo on their website:

Latigo is a combination tanned leather with a full vegetable re-tan; well nourished with a rich proprietary blended oil emulsion. Characterized by beautiful tight grain, Latigo has come a long way from its cowboy origins— the old days of saddle straps and hand staining. Modern Latigo retains its toughness while showing a rich look that improves with age and use. This leather blends the durability of a chrome tan base with a heavy veg re-tan to create an unfinished, natural look that’s excellent for molding. It holds embosses well, retains molded shapes and has both full and corrected grain versions.

California Latigo 4/5 ounce from The Hide House.

Wow, those pieces look great! Do you find that it's easier or harder to cut into latigo than veg tan? What makes you choose latigo over other kinds of leather for your pieces?

-

Hey all,

I'm trying to get some more information about latigo leather, such as use cases, history of the leather process (if anyone knows), and any general trivia that people might know. Thanks so much for your help!

-

I recently acquired a Bob Douglas awl haft and blade, and I must say - the awl haft is brilliant. I was dreading installing the blade in the haft on account of not having a vise to hold the blade between two pennies nor having experience with working with epoxy to stick the blade in. To install the blade into the Bob Douglas haft, you simply unscrew the ferrule nut, insert the blade, then tighten the nut. It self-centers, and it's brilliantly simple to swap between blades. Truly a work of functional art.

-

This looks amazing!!! How long did it take? If you’re a hobbyist and not looking to depend on it to support you, I’d actually price it higher (maybe somewhere between $100-$150?) since you’re not in a rush to sell. I could be way off on that though - just my 2c.

-

6 hours ago, Bert03241 said:I make my own delrin stamps and just use a mallets works fine.

Hmm okay! The maker said that using a maul might damage it, so I was worried about that - thanks!

-

4 hours ago, MtlBiker said:I hate to be a wet blanket, but it's very hard to sell and be profitable on Etsy these days. There's just too much competition and much of it is mass produced in a factory somewhere. People have a hard time appreciating the value of hand-crafted one at a time products. I'm planning to make a case like this myself (already bought the pattern and viewed the video before you posted) but I'm under no illusion that I can sell it profitably. Just for example, look at this leather case for the Airpod Pro. And personally I like this style better but making it is well beyond my skill level at the moment. What I like is that it's molded and when you open it, it's one piece rather than having to open the top flap of the case and then the airpod case. And by the way, the one I linked to is only about US$26. So selling one for $60 is going to be tough.

But more power to ya!

Ah, I’ve already got some sales, so hopefully it keeps up!

-

On 2/28/2022 at 8:25 PM, HandyDave said:You say makers mark so im guessing the delrin stamp in question is relatively small in size? If so you probably could get by with some sort of clamp for a small makers mark stamp. A press is the best way to go for sure. I use a 12 ton shop press from northern tool a bigger press like this can be used for alot more then the arbor presses and there about the same cost as a good arbor press. With the bigger press you can set up for bigger delrin stamps and embossing plates along with clicker dies if you plan to advance in the future. Buy once, cry once.

I’m a bit cramped for space, so I won’t be able to get that big of a press. Will look into some smaller arbor presses though!

13 hours ago, PastorBob said:As mentioned above, a cheap arbor press from HF would work great, but you can also sandwich your stamp and leather between a table top and a piece of wood and slowly crank down some C-clamps...leave it for about 15 seconds or so, depending on how wet and thick your leather piece is.

Thanks, PastorBob! I think that wood tip is handy - I’ll keep that in mind.

5 hours ago, bgentle said:I use them with a nylon hammer. Works just fine.

Hm, I think I’d have trouble keep the stamp in place - any suggestions for that?

-

On 2/28/2022 at 8:15 PM, mrwatch said:Delrin is a synthetic material that has been used for pocketknife handles for years. I would suggest an arbor press with a hole for the shaft and many do not come that way. Or maybe a modified large C clamp.

Great! I think that C clamp tip will be handy.

-

17 hours ago, MedusaOblongata said:If you're going to use pliers, wrap the jaws in electrical tape. It adds a little bit of grip and won't scuff the needle. Hopefully you won't need to use them on every stitch, because that would take a long time and be annoying. See if a smaller needle or larger hole is a possibility.

Tbh this is a great suggestion: applying the electrical tape on my Kleins now!

-

1 hour ago, koshkimishki said:Nice case, apple original cases are very expensive

Thanks @koshkimishki! Yeah, they are. With the polishing touches that @MtlBiker suggested above, I’d probably price this on Etsy at $60, which I think is reasonable in comparison to the mass-produced cases that Apple sells.

-

20 hours ago, MtlBiker said:@benfanman - I'm a fine one to talk (being just a beginner with leather myself) but your edges sure could do with some finishing.

They do look a little rough. Maybe (in the future) a little sanding first, followed by some tokinole and a polishing.

They do look a little rough. Maybe (in the future) a little sanding first, followed by some tokinole and a polishing.

Nah definitely, this was the first one I ever made, and it’ll be staying with me at home. Just wanted to see how the pattern fit! Thanks for the recommendations.

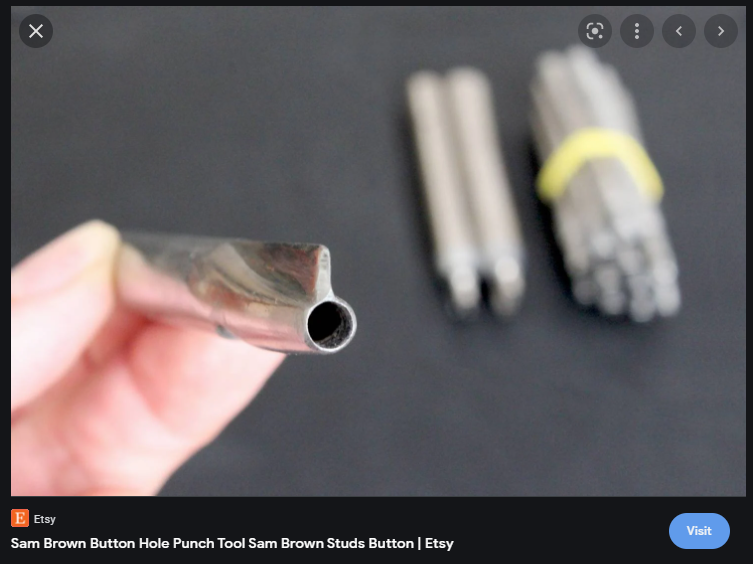

8 hours ago, PastorBob said:Thanks for sharing your work! Always great to see another artisan's work. That closure is referred to as "ball and post" or "Sam Brown". Something you might add to allow it to open a little easier is a tiny slit on the edge of the hole. Place the slit on the opposite side of the direction where there is natural tension when the case is closed (I would guess on the side of the hole farthest away from the edge. Great work!!

Not that you have to purchase a tool for the hole, you can use a blade to slit it, but here is a picture of a tool used to make the Sam Brown hole. This will give you an idea of what I described above.

Hey PastorBob, thanks so much for the encouraging words! That’s an awesome suggestion - I only have one of these (since it was ordered as a mistake), so I haven’t really explored the best practices on how to craft around it. I’ll make sure to try that out tonight!

Thanks again for the information, it was very helpful!

-

I actually use a pair of Kleins (I think they're formally called lineman's pliers) that does the trick beautifully and easily, thanks to the heavy weight of the tool.

-

Hey all,

So, I recently got some delrin stamps from @allgoodleather (on Instagram), but I'm worried about how to manually press them into the leather. I've been using a maul for a custom stamp that I got from Springfield Leather, but that stamp is metal. Anyone have any recommendations for how I should stamp in my maker's mark without buying an arbor press/some kind of machine? Thanks in advance for the help!

Best,

Ben

-

Hey MtlBiker,

Thanks! Yeah, I'd say this is a pretty easy project to do (provided you have the right hardware).

As for the leather, I lack a leather gauge and found this old scrap in the box, so I'd guess it's about 5 oz. I've never bought anything more than 5 oz, so it would be pretty unlikely that it was 6 oz.

-

Hey all, looking forward to meeting you all! I discovered leatherworker.net early 2021 but never made an account until this year. Thankful for all the great information I've found on here, and excited to be a part of the community!

I'm currently doing my PhD in Philosophy at the University of Maryland, College Park, and I have an Instagram account for all my leather-related updates @diffleatherco. Would love to follow you all back! I've attached a picture of the logo my wife designed for me when I first got started.

-

needle keeps getting stuck

in How Do I Do That?

Posted · Report reply

This is actually kinda clever - might use it if I can't find my rubber glove fingers!