WeiFeng

Members-

Posts

16 -

Joined

-

Last visited

WeiFeng's Achievements

Member (2/4)

-

Yeah, see, that’s the thing about shopping for the best tools that you can afford as opposed to purchasing something that will barely get you by just because it’s cheap. As you’ve accurately pointed out, there most likely projects ahead that I may never have seen coming that probably have nothing to do with auto upholstery. See, now those are the words of an experienced voice that will take some time before I am able to express, but in the mean time I can do everything possible to prepare myself with the right type of equipment. I have not seen all of his videos, but I watched quite a few, though, and I too am a big fan. That guy is extremely talented. After discovering that there are a few more things to consider when searching for a double needle machine as opposed to the single needles, the availability between the groups are vastly different. There are a lot less double needle machines on the market then there are single needle machines. This disparity presents a huge problem in terms of searching for any particular model of machine. To make matters worst I find it hard to put faith in most of what can be found on Fleebay. This is starting to feel like finding the right machine may take a lot longer than I had imagined.

-

Accuracy along with my skill level is the whole point of this exercise. Again, this is the point. In my case (at least for now) I am my own customer. I ultimately decided to take on the challenge of reupholstering my own cars interiors primarily because I couldn’t find anyone that I could trust to provide the results that I wanted. Some years back I was referred to a guy in Southern California that was supposedly an expert in recovering the original Recaro seats (Classic C & Ideal C) from the 1980’s. I live in the Midwest and drove the 2,000 miles and hand delivered the two chairs, all of the panels, and the hand selected matching leather that was obtained from the Hide House up in Napa. It took the better part of a year before I was able to get the parts back, and the labor still set me back a big chunk of change. In all fairness at that time the guy was semi retired, but nonetheless he has since then closed up shop. He did a wonderful job, though. Since then I have searched tirelessly trying to find someone else that is able to reupholster these Recaro chairs. Believe it or not, all that I have approached either said they are unable or I’ll see what I can do. Well, rather than seeing what someone else can do (which I find totally unacceptable) I decided to see what I can do myself. The reason being is my own satisfaction level. If I do it and it doesn’t meet my satisfaction there won’t be anyone to blame and I can live with that, but if someone else doesn’t meet expectations I will still have to pay for it. Also, I’d be crazy to go to all this trouble for one set of chairs as I have several other cars to deal with. I expect that at some point through this process my competence level will become satisfactory. In order to do this, I just like all of you will have to brave the gauntlet, and one of the best way to go into battle is to have the best tools for the job, thus the double needle sewing machine.

-

You are 100% correct and aren’t missing anything. The double needle machine is solely sought after to mask my own inexperience. Those parallel stitches are the finishing touches to any upholstery project. The eye is immediately drawn to the visual effect of how well the stitches are laid down. In my mind, if the stitches are well proportioned and evenly spaced then the only thing that I would have to worry about is sewing a straight line once. Of course if I am unable to locate a machine that is able to handle the larger thread sizes at what I may deem a reasonable price, I will obviously be forced to grind out those seams one at a time like you guys are able to.

-

Ah ha, the plot thickens, and all that glitters is truly not gold. It is so true that the more you know, the more you need to know. The double needle will obviously hold down the folded edge (I don’t know the technical term) but the top stitches will be more of a decorative pattern, which brings the thread size to the fore. My guess is a 138 thread size would be considered standard, or maybe a minimum in terms of visual appeal. It seems to me that when pursuing needle feed machines it behooves you to know all of the particular nuances of said machine. That great money saving deal could potentially end up exceeding the cost of the more expensive machine that should have been purchased in the first place. Therein lies one of the main differences between the various material feeding systems, and as I think about it (which now seems foolishly obvious) the material as well as sewing style will pretty much dictate the appropriate type of machine that is needed to accomplish the particular job. In my case material thickness is negligible, sewing speed is a none event, compound feed isn’t exceedingly necessary, but at the end of the day it seems that a machine capable of handling larger thread sizes of say 138 - 207 will likely rule the day. I can only imagine how much more narrow the field of search has shrunk with this new revelation.

-

Would you happen to know the largest thread size that these machines can handle?

-

This is an interesting piece of information. I can see how it will help broaden the search to include these other options that you mention. Although I’d like to have a feature rich machine any day of the week, the reality is a double needle machine will be used as a dedicated single purpose tool for producing French seams, and realistically, it will only see occasional use. I obviously have no way of knowing where this endeavor will lead in terms of mandating a triple feed machine, but depending on which machine I am able to secure at the start of this project, I will cross whatever bridges I come to when I get to them. As far as I have come to know, those automatic oiling machines aren’t necessarily the right tool for the jobs that I want to do. If I’m not mistaken, don’t those automatic oilers have oil pans underneath with some sort of pump that lubricates the machine while it is in use? If indeed that is how they work, then that would seem to make any one of them inappropriate for the style of sewing that I envision for myself. Isn’t the function of the self oilers predicated on high speed of the machines in order for the oil to flow through the system? Contrary to that type of speed, I will be looking to slow the machine down to crawling speeds which would seem to mean that the machine would almost always be running dry, because that pumping action would never be able to do it’s job. I’m of the mindset that a self oiler would be most appropriate. I appreciate the insight, very helpful

-

Awesome, that spells things out very clearly. What an education. Best regards

-

I do have on other question, though, because I don’t see any mention of a walking foot in any of the machines being sold. Is it standard operating procedure to have a walking foot on all double needle machines, or do they have to specifically say walking foot?

-

Ah, ha, I totally did not know that, and was drowning in all of those numbers, good stuff. I do believe that you’ve hit the nail squarely on the head with that sage advise, and guidance. With all things being equal, the inability to source needle spacers kinda renders the machine pretty much useless. I think I’ll move on and continue the search, Thank you

-

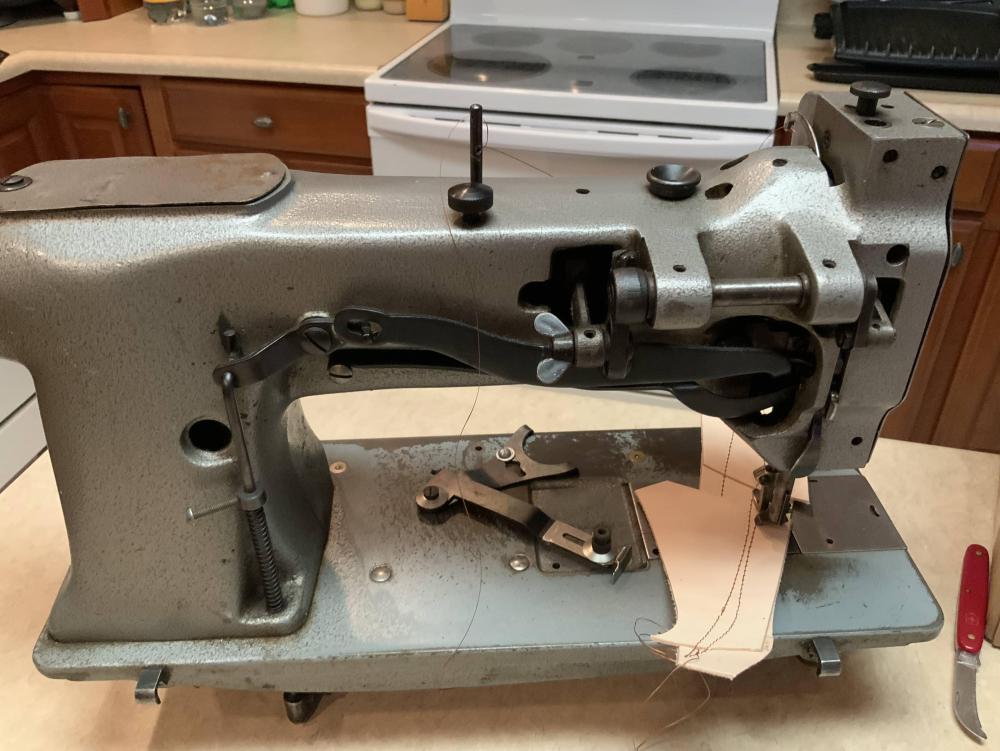

Hello all, I’ve been slowly gathering the tools to redo the upholstery in my cars and with the help of this forum you have helped me successfully identify the first Consew 226 that I picked up a few weeks ago. I am back in the market for a double needle machine and found a Pfaff machine but cannot make heads or tales or find any pertinent information on the machine. It is a Pfaff 442-6101-900/51-BSN double needle machine. I am seeking a double needle machine to be used primarily for sewing French seams. At this point I am not sure how functional the machine is, but as I stated earlier the internet is not providing any information on the machine or any possible needed parts. Any help will be appreciated, Best regards

-

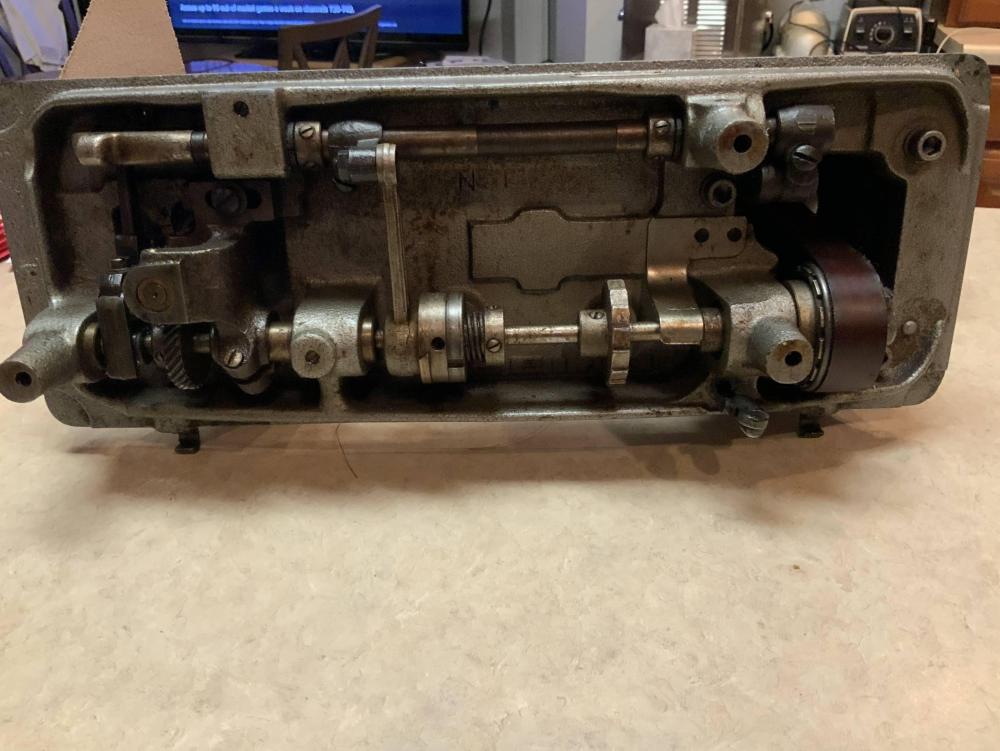

Wow this is precisely the information that I was looking for, so thank you all. I will soon get started on cleaning things up a bit and perhaps change the belts. I’ve seen one of the hook & needle timing videos that another contributor was kind enough to produce, so I will work my way towards checking that out in due course. As I eluded to earlier, the 225 came setup on a table with a clutch motor and a servo. I am thinking of investigating the what it would take to reduce the size of the wheel that is attached to the motor in order to slow down the machine to crawling/walking speeds which should aid in my learning curve. Are there any particular solvent based cleaners that is recommended to cleanup the internal gearing (perhaps Simple Green?) I am not exactly sure about needle sizes as it pertains to different fabrics and threads, but the machine came with two packs of needles, bobbins, and the thread that he was using. Is it true that this machine will sew 138 thread up to ⅜” thickness? I don’t have a clue as to how to tell the thread thickness. I am also unclear as to the numbering system pertaining to needle sizes. I read on hear somewhere that #22 needle is used for leather, but that in and of itself doesn’t mean a whole lot to me. Ignorance is not at all blissful.

-

Thank you. I obviously don’t have a manual. Any idea how to adjust the thread length? And, while I’m at it, are there any recommended suppliers to get quality welting feet and other attachments? Don’t want to buy any old pieces of junk.

-

-

-