LanceR

-

Content Count

35 -

Joined

-

Last visited

Posts posted by LanceR

-

-

-

A quick look at the Winston-Salem CL pages for sewing machines and including nearby (within two hours) shows Brother CB3-B917-1 button machine FOR $800, Brother DB20736-3 FOR $625,Brother DB2-B714-3 $575, three Singer 20U33s from $375 to $750, a Juki 562 and Consew 226R-1 from the same seller for $1K each, a Wilcox & Gibbs serger for $350 and a pair of Reliables for $450 each (model unknown). All are in tables and under power......

As you would expect, I've seen darn few post bed or cylinder arm machines and most of those go far to high for me as any use I'd have for them would be more aspirational that real. That $375 20u33 is really clean and if I didn't already have a nice smaller machine I'd go look at it. It's less than an hour away.

For the Outer Banks you would do well to look at the Eastern NC CL page, Wilmington, NC, Norfolk or Virginia Beach, VA ect depending on where you'll be. We're a half hour north of where I40 passes through Winston-Salem and an hour south of the intersection of I81 and I77 in VA. If you're out this way give me a shout.

Best regards,

Lance

-

Hey, Don

Here in Pinnacle, North Carolina (a half hour north of Winston-Salem) there are literally a few hundred former mills and furniture factories withing 100 miles most of which a now idle. And there are still a bunch working, too. There are an awful lot of industrial machines in the region and 1-1/2 to 2 years ago it was common to see 5-10 on the various Craigslist site in the region. For the last year there have been darn few and although more are showing up it still hasn't gotten back to where it was and most prices are still up.

Best regards,

Lance

-

Thanks, Don

Those are some very well done videos. Both presser feet are missing so I'll whistle up those and maybe a few others while I'm at it. Checking the stitch length without them is tough.

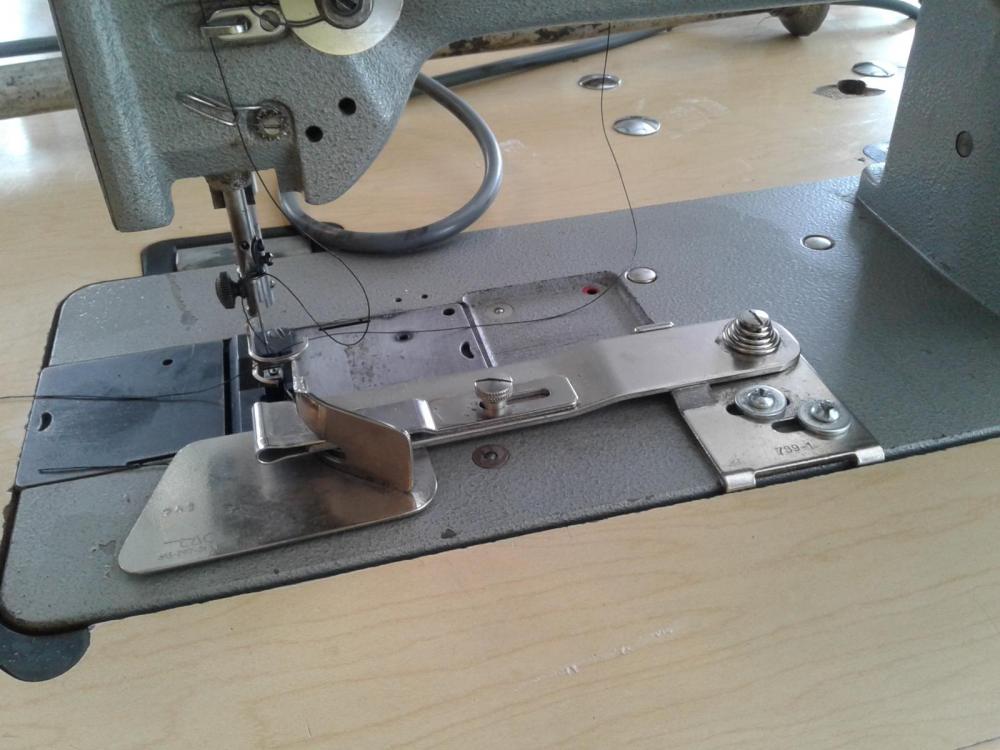

The stitch length adjustment had me baffled as the machine has an index wheel that sits inboard of the handwheel and it was out of index as the picture below shows when it was, in fact at the longest stitch length adjustment. I engaged the adjustment pin and confirmed the setting of the stitch at its longest length and indexed the wheel and tighten the set screw. Using a piece of card stock and trying to hold it down as the needle retracted I came up a little short of an inch with five stitch intervals and the stitch length set at a nominal 5 stitches per inch. It will have to wait for presser feet to do any final adjustments of the forward and reverse stitches.

The timing seems perfect and it's been cleaned and lubed so there's not much left to do until I get a new motor and presser feet.

Again, thanks and best regards,

Lance

-

Whatever the guide is for, it swings away. The underside and inside of the machine is pretty clean but dry as it seems to have been sitting for a while before the auction. At least it had a fabric dust cover over it..... I took the three phase motor off, removed the bobbin case and cleaned and lubed under it and put the case back in and started cleaning and lubing the rest of it.

Upon further research, the Consew 226R-2 seems to be more like the Singer 111W156 than the 111W155 as the 226R and the 111W156 have reverse. The Consew seems to have a 5-24 stitch per inch range. The only manuals I've been able to find are Singer PDFs with blurry pictures that are pretty tough to see any detail in. If anyone has a link to something better, I'd really appreciate it and I'd love to have a shop manual for it.

Can anyone tell me how the stitch length adjusts? I get that the left of the two spring loaded buttons on the base locks the shaft collar but what do I turn then, just the handwheel of the numbered ring on the onboard side of the handwheel and what is the index mark or point?

And what presser feet should I be getting to start out with?

Thanks and best regards,

Lance

-

Thanks for the info, Folks.

Don, having a good relationship with the riggers was always a good thing for being able to better outfit your vehicle with custom stowage, padding, carry bags and covers. One or two dozen doughnuts could go a long way in the rigger's shed.

Best regards,

Lance

-

Greetings to all

I'm pretty new to sewing in general. My initial interest was for sewing canoe spray covers, portage packs, climbing rope bags etc. Some of those, especially the packs, get into several layers of canvas or duck, particularly where seams cross and the packs include leather straps, backing pads etc.

I have a 1950s Necchi BU Mira in an industrial style table for middle and light weight stuff but want to move up to heavier fabrics and leather so I brought home a Consew 226R-2 yesterday from an auction (that came with a Pegasus EXT 3216-03 serger in the same lot). I'm into both machines for less than $200 right now. Both have three phase clutch motors and I'm darned if I want to run my 5-HP rotary phase converter for sewing so I'm in the market for a motor for the Consew.

And although I found the parts manual online for the 226R-2 I can't seem to find a model specific operator's manual or a shop manual for it. Any help in pointing me in the correct direction would be greatly appreciated. It's made in Japan and the serial number is WBA0212590.

The Consew came with an attached guide and any insight into just whether it's worth keeping would be appreciated. It sure doesn't look to be something that can be quickly removed (unless it's some sort of swing away guide?).

So, although I don't yet have plans to sew any heavy leather, what kind of leather should I expect to be able to sew and since that answer may be tied to the motor choice I guess that's the place to start. I'm leaning towards a variable speed servo motor but remain open to suggestions. I'd like to keep the cost to $200-250 or so but if that's not reasonable I can go higher. High speed is definitely not needed. Lower speed, especially if more torque consistent with not breaking things is available is a plus.

And suggestions as to what accessories I should be looking for would be very much appreciated.

In the next few days I'll be removing the clutch motor, cleaning and lubricating everything and checking the timing, feed dog height etc so I may be back with more questions.

Thanks and best regards to all,

Lance

-

Hello and best wishes to all

I've been lurking for some time while trying to figure out my next steps in the sewing world and as I want to make some stuff with several layers of heavy fabric and leather I've been spelunking around the internet in search of enlightenment. Which led me here....

I have a Necchi BU Mira, a beautifully made 1950s Italian made machine in an industrial type table with an old school Atlas clutch motor that I cleaned up and made a new friction disc for that is fine for lighter stuff and punches well above its weight on occasional heavy webbing and multiple layers of pack cloth and lighter canvas and duck. But I want to start into heavier things by making some portage packs for canoe trips starting with something similar to the Duluth #30-70 Utility 84 liter pack and working up to something like the #4 Monarch 84 liter pack. Both involve leather straps and backing pads that the Necchi would not be a good candidate for so I just brought a Consew 226R-2 home yesterday to use while I learn more about where I'm headed in sewing and leather-craft.

https://www.duluthpack.com/products/3-70-utility-84l

https://www.duluthpack.com/products/4-monarch-79l

So, thanks for having me and I look forward to being here.

Best regards to all,

Lance Robson

Thread/needle choices for sewing leather straps to canvas?

in Leather Sewing Machines

Posted · Report reply

Hello All

I have a Consew 226R-2 and need advice on starting points for needle/thread choices for sewing Duluth canoe pack style canoe packs in 15-18 ounce canvas and for attaching straps and backing pads to them. I'm looking to use similar construction techniques to the Duluth canoe pack shown here.

And using backing pads like these:

Any help with recommended thread/needle combinations for the canvas seams and the leather pads would be appreciated. I suspect the leather for the shoulder straps wants to be in the 8-9 oz range but any thoughts on that weight and the weight for the closure straps would also be helpful.

Thanks and best regards to all,

Lance