29k15engine

Members-

Posts

54 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

29k15engine's Achievements

Member (2/4)

-

29k15 Shuttle Rack and base plate DXF files

29k15engine replied to 29k15engine's topic in 3D Printers and Lasers

Here are the files in their stl format for 3d printing, the rack extended for welding is a bit longer to ease welding onto the original or new rack rod.(also in dwx) ideal plate.STL ideal rack extended for welding.DXF ideal rack extended for welding.STL ideal rack.STL ideal shuttle5-25mmdia.STL -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Here are the files in their stl format for 3d printing, the rack extended for welding is a bit longer to ease welding onto the original or new rack rod.(also in dwx) ideal plate.STL ideal rack extended for welding.STL ideal rack.STL ideal shuttle5-25mmdia.STL ideal rack extended for welding.DXF -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Hi thanks for the reply, Due to these machines not having an adjustment for shuttle timing the length of the full rack would be subtly different from machine to machine after 100 so years. due to this I have worked on an adjustable rack (see earlier posts) which would allow timing adjustment equivalent to the later machines with a eccentric bush. If you look at earlier posts you will find an old 60s catalogue picture from italy which shows the replacement rack end as a weld on item, so without the adjustable rack the end can be replaced on an existing machine rack (with care) -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

After much work these are the DXF files required to cut correctly profiled shuttle gears for the 29k15 Singer Patcher, although I have extensively tested these on my machine I take no responsibility that these fir yours, they are however ovet 6 month work and are as accurate as i can make. These can be cut with an EDM wire erosion machine from a suitable steel (Hardened tool Steel) I will provide side profile drawings for the depth to cut the shuttle gear after the EDM has cut the gear profile. I have tweaked the shuttle so it does not need to be reamed out to correct pinion size. thickness for pieces before being cut on EDM, surface grind to these sizes, ideal shuttle5-25mmdia.DXF Description:- pinion gear 6.68mm ideal rack.DXF Description:- rack 3.8mm ideal plate.DXF Description:-Locating plate 2.73mm thick ideal shuttle5-25mmdia.DXF ideal rack.DXF ideal plate.DXF -

After much work these are the DXF files required to cut correctly profiled shuttle gears for the 29k15 Singer Patcher, although I have extensively tested these on my machine I take no responsibility that these fir yours, they are however ovet 6 month work and are as accurate as i can make. These can be cut with an EDM wire erosion machine from a suitable steel (Hardened tool Steel) I will provide side profile drawings for the depth to cut the shuttle gear after the EDM has cut the gear profile. thickness for pieces before being cut on EDM, surface grind to these sizes, ideal shuttle5-25mmdia.DXF Description:- pinion gear 6.68mm ideal rack.DXF Description:- rack 3.8mm ideal plate.DXF Description:-Locating plate 2.73mm thick ideal shuttle5-25mmdia.DXF ideal rack.DXF ideal plate.DXF

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Just threaded up the machine and it stiches perfectly. Fine through 2 pieces of 1mm leather and 6 peices of 1mm leather ! -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Here you go all parts fit in the 29k15. The gear thickness needs to be spot on as it is sandwiched between the arm and bottom plate. The bottom plate needed a slight file to the two long sided so it seated where the screw and pinion bearings wanted it to go( we are talking a few thou) The hole in the gears was made undersize to allow differences in pinion wear( ream to fit your machine) My friend used hardened tool steel so only a hardened tip drill would do the job. Next job is make up the adjustable rack. Getting there now, i will post the gear , rack and base DXF files soon for anyone to try them in their machines https://1drv.ms/v/s!AoQ4CZYzE-ZEkWlLataRevmLAfCu -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok so after many weeks my friend has got the peices done on a wire erosion machine, what a good job was done! I have tried the rack part which meshes perfectly with both original pinion gears and the machine itself. So does the bottom plate i had made. The new gears mesh perfectly with each other and original gears. I have yet to hone them to fit the pinions in the bottom 29k arm ( made them to hone as i didnt want to go through all this to find them too loose. Plus after that they need the lower bearing shoulder to locate in the bottom plate. So ill be back soon. After this i can let you have the universal files so you can make your own. -

Singer Patcher 29k53 - not picking up bobbin thread

29k15engine replied to LomaeArts's topic in Leather Sewing Machines

After looking at the video that is a timing issue, have a look at my 29k15 timed correctly an now never missing a stitch, you are lucky you have an eccentric bush to adjust, i lengthened my rack a fraction on a new rack i bought from italy. https://1drv.ms/v/s!AoQ4CZYzE-ZEjinebhd-7y_c5KCi As constabulary stated you need overlap of the needle hole in it most anticlockwise movement, fix that and you will have a fighting chance -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

will do, just waiting for the gears to be cut, in the mean time Im redecorating our bathroom, plastering and tiling is not fun -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

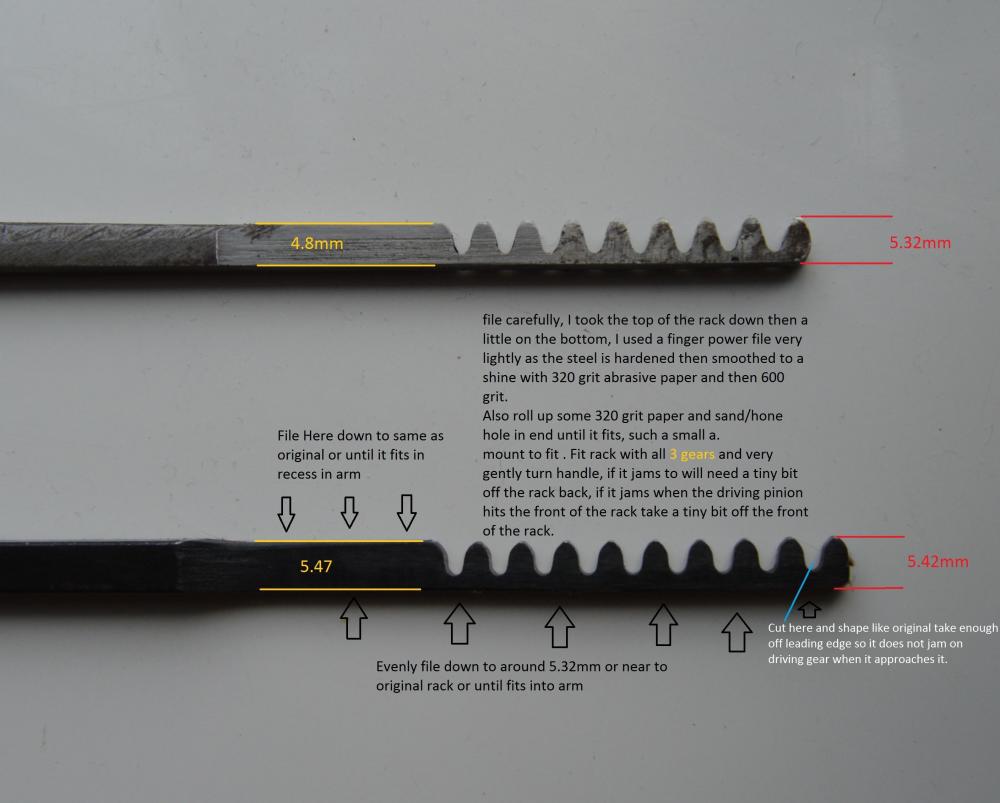

Ok so bit of an update, I am very happy with the racks supplied from Italy, part 8600 this can be easily modified to fit the 29k15 and like machines as described below. Part 8599 also stocked in italy can also be adapted to make a 29k15 rack. I am also proceeding with the development of an adjustable rack to reset the shuttle timing to stop drop stitches and timing issues. I have also recieved supply from italy of 8608 following gears for the 29k1, unfortunately the gear does not fit easily in the 29k15, the dimensions of the gear teeth are too fat to mesh properly without alot of teeth root filing and thickness, for me that is a no no, with the rack mods below all the filing is on the backs and not on the teeth. I believe these 8608 gears will fit the 29k1 as the tollerances needed in combination with the long and short rack are not as critical as the 29k15 3 gear 1 rack system. In fact I am starting to believe that the only way singer got the 3 gears to perform to the tollerances needed was to "finish the 3 gears (2 followers and 1 driving gear)" by finish I mean run them together on a jig until they cleanly meshed and ran smoothly, this may be collaborated by the fact that 29k15 gears have punch marks on the sides of the gears where they were originally meshed, rear follower one puch middle follower 2 punches and the driving shuttle gear 1 punch. I am still therefore pressing onward to get these EDM cut gears, this will mean I can get gears cut accurately that will be a guaranteed fit without any rework after and therefore be the only new rack and gear designs and sets that fit to the 29k15s out of the box in the world. any thoughts on these finding would be appreciated. Any thoughts on my findings -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

You got me interested Chris, are we talking sintering? Do you have a web link of an example company in the US that would do this?

.thumb.jpg.b7f2f6adc82abef6d52e94ff0ea3fa90.jpg)