29k15engine

Members-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by 29k15engine

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

I am now working with the theory that the 29k1 machines did use follower gear 8608 then when the 29k12 came along they used 8608 but with tighter dimensions, looking at lots of gears now even unused ones the K1 gears look thicker in the teeth, I do not put this down to wear as my gears are very very good but there is no way a fatter toothed gear would fit when meshed with the adjoining fatter gear. Therefore Im going to press on with my 29k15 (im encompassing all the revisions from k12 to k15 and k20) gear modelling and cutting research. -

My first leather jacket

29k15engine replied to 29k15engine's topic in Clothing, Jackets, Vests and Chaps

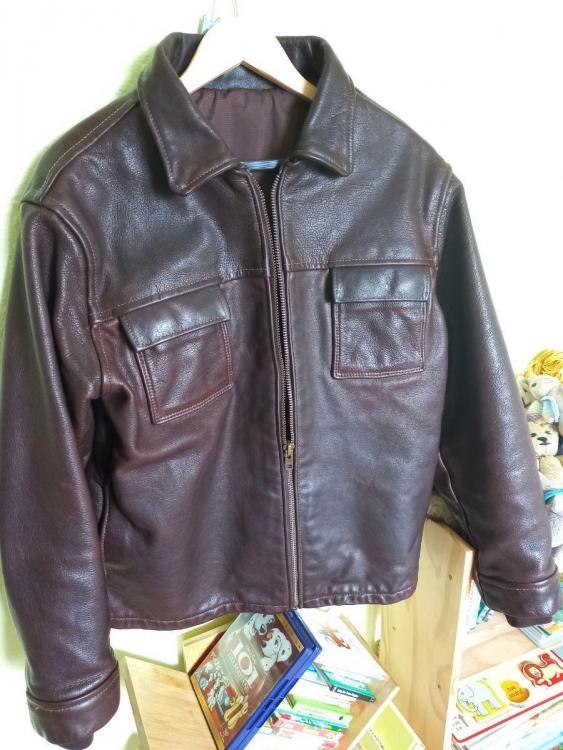

Im happy with how it all went, the jacket is too heavy for daily use. I think though if I can make a thick one then a thinner will be easier. Just on the lookout for come nice leather or nappa around 0.8mm. Hope you like it -

I thought I would share some pictures of my first leather jacket I made. I have had a leather/nubuck jacket from GAP for 20 years, I really loved it and alway wondered if I could maybe make one. Quite quickly I realised a household machine was not going to work, so I bought a speedy stitcher and a stitch wheel. With these trusty tools I set about making templates of my jacket taking note of the felled and half felled seams. Once I was happy with this I did a few trials of how much seam was needed for the desired result. With seams added to the pattern I started to cut out the pattern.

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok so I got my new part 8606 following pinion which is used on the 29K1 machines in a 2 cog configuration with a long and a small rack as shown below and also on the 29k15 machines as a 3 cog one long rack configuration show below. So as you know I have been modelling the cogs and rack for the 29K15. I have found a supplier of the cog which I have recieved today. Unfortunately the cogs do not mesh with the 29k15 3 gear setup, this is due to a couple of dimensions being different, I am wondering if on the 2 cog design the tollerances of the pinion did not need to be as accurate as it is just picking up on 2 racks and not 3 cogs and rack. Below is an image of the 8606 cogs recieved. One looks slightly different on the tooth from the other. When measured against my good original gears that fit like a glove I find the dimensions below different. The tooth is thicker 2.51mm not 2.16mm each tooth is 0.25mm thicker and the root of the gear is not as deep 9.10mm not 8.48mm difference of 0.31mm shallower root to the gear If I place the two new gears onto the lower plate of the gearbox the gears do not allow the gears to turn as there is no room for them to move. So I am hopefull that the cogs being made by my friend on an EDM machine will be better fitting than these. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok bit of an update, still waiting for my friend to cut the gears out of metal. Meanwhile I have just recieved new follower pinion gears from spain, part no 8608 and found they are so close to what they should be but do not fit. I will post an image of the gears, it seems that the teeth are too thick by around 0.38mm plus the root of the gear is not deep enough by 0.38mm -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Thanks people, after reading the specs of EDM i've been tweaking the gears and measuring my good gear over and over to make sure I give it my best shot. I am also getting them to cut the bottom plate so I can put all the parts together. Here is what is going to the EDM, on paper no interference issues.....we will see. If and when I get this "right" I can then provide STL and DXF so people can get these parts made locally, though the tollerances are so tight I am also looking to make these myself to keep the quality and fit right, time will tell on this. I would love to do this the old fashioned way with dividing head and hobber but I don't have a lathe or enough knowledge of hobber design to get it right,,,yet! https://1drv.ms/v/s!Arc9igKuarE5gSUtRwX55Ou3oxz- The other research on parts still available is hopefully going to bear fruit. I have the following parts ordered from Ital and Spain. 8608 New pinion gear, I don't yet know if these are in short supply and therefore NOS "new old stock" 8600 New Rack for 29k1 but same rack profile as 29k15 range so can be cut and extended for use on 29k15 or as it on K1 8599 New Small rack used on K1 but could be a donor to be grafted to long rod for k15 So judging what these parts are like quality etc it will offer two routes to getting gears for these values and treasured machines where initially there was none. I would also like to make an adjustable rack rod so fine tuning of shuttle movement can be achieved like the later machines. One of the main drivers for me to do this is when I contacted the singer archives I was informed that most if not all of the singer designs and drawings were destroyed in the 80s when the factory was demolished, thats 150 years worth of engineering expertise translated to complex designs and drawings, to reverse engineer like I am doing you really appreciate what they achieved 100 years ago. If these parts are preserved in computer formats that people can use to replace these parts then these machines could go on for another 100 years. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Excellent thanks Chris, My friends 3d printer is a ELEGOO Mars Pro MSLA 3D Printer so prints with more accuracy. We are having a go with a Wire EDM machine to try it in steel to make 1 prototype , we will see. It good work to see how accurate these processes really are. Im also looking at having them laser cut but am unsure on the accuracy needed if I went this way. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok I have revised the drawings over the past few days, is is the most accurate. I used a microscope to image both the cogs and rack. Nearly there now. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Video of parts moving also shows where they need a shade more room to move 29k15 shuttle prototype video -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok just done some measuring compared to my good gears, the differences are 0.1mm on cog tooth thickness ie prototype is thicker and diameter of cog overall needs to be .2mm less apart from that not alot needs to change. Have a comment if you can critique more the merrier. Her are the parts fitted to the base plate, little tight but these changes may be all that is needed. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Steel these are just for prototyping -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Ok so my pal dropped of an evelioe with the parts he made on his new 3d printer. I was hoping for the best but like all things engineering prepared for the worst... however they fit!! Like a glove I need to tweak the end of the gear tooths a little but first fit is good. As the tooth end is a little too accurate they need a micron or 2 more clearance. Have a look, comments and critique welcome. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Just found from a supplier I can get parts 8608 Following Pinion for both 29k1 but also following pinions for 29k15 and the like. 8599 Small rack plus 8600 long rack!! which I may be able to be modified to fit a 29k15 with an adjustable rack rod. These are all new parts. Will keep you informed on these as it is another direction to get these parts working the older machines. Here is a picture from the supplier of part 8600 in stock. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Hi Don, feel free to think out loud, having modelled the gear as well I have tweaked both to do the 3d print, here are the latest drawings. I got the gear and rack to mesh with 0.001mm and no interference on full rotation with all 3 gears in correct position, so we will see when my friend pops round with the prints. In my book it talks about lantern gears which were very round. My final drawings are not as round so we will see how they actaully mesh. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Going to get the fit right with lots of testing, then hopefully will have an STL file for people to try. The straight forward job would be to provide matching gears and racks. However the harder but more rewarding job will be to provide parts that can be used with genuine singer rack or singer gears therefore being equal in fit to OEM, thats the bit that will take a little time. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Thanks for that, i have a book on gears and gear construction, i believe the gears these days are not constructed like this anymore, indeed in the gearbox of the 29k the gear profile evolved with different tooth profiles for the 3 gear used in production. For this reason, i decided to start modelling the gears from actual measurements of a good rack and pinion gear. This way it won't get bogged down by calculation that if slightly wrong will not product the right profile. I can get these 3d printed in plastic and then cut in steel by a friend. But only when they fit and work. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Just done a render of the rack on a 29k15 which would be a soldered on item that would replace the end of a worn out rack. This is acurately measured and constructed therefore I need to make one to see if it works, I have a friend with a 3d printer who can also make one out of steel at work from a 3d file. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

-

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Thanks jimi, I used google translate, then took a chance and ordered the parts. Hopefully these parts are what i need. I think the k1 machines used the same follower gears as the k15 just in a configuaration of 3 gears not 2 and a short rack, time will tell. Im quite interested in making gears for these, i really need a hobby lathe or mill, or make a small dedicated machine to cut these. The more i learn about gear cutting and " hobbing" the more doable it looks. The rack would also need to be made which could if i was to make it have a length adjustment built in to fine tune shuttle timing. -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Note the lining is hard to learn until you realise you are duplicating the jacket just in material, then with a few tweaks you can get it to sit flat inside, note sleeve lining benefits from more rather than less space to move your arm -

29k15 shuttle gear remanufacturing

29k15engine replied to 29k15engine's topic in Leather Sewing Machines

Thanks for the kind words on the jacket. I do have the pattern for the jacket somewhere. The way i did the pattern was to pattern another jacket i had, panel edge to panel edge then add the seam needed depending on what the seam was e.g full felled seam. I made a mock up of the jacket in automotive fabric i had around as it had a scrim back which had depth to it to try out the seams. As said the leather is heavy making the jacket too heavy for day to day use, the way i look at it is if you can make a heavy jacket and work out all the folded seams, then a thinner one will be alot easier. The thicker the jacket the more the fit plays its role, i know very little about tailoring but would say the most important area to get right is how it sits on the top of the shoulder and around the neck, the thicker the leather the more this area matters. Also with the seams skiving and hammering the leather is needed to get up to 5 thicknesses to lay right. Lessons i would pass on to my next jacket. 1. Choose the leather carefully, go thinner rather than thick 0.8mm initially ( look at how the leather reacts when its folded and doubled up as some seams may require this) 2. Make a full mock up of the jacket in a cheap appropriatley thick fabric with ample seams to get the fit right around the neck, shoulders and arms 3. Under the arms should go up to the armpit, the higher this area is tailored the better the jacket will move and thus not lift the jacket when you put your arms in the air. However give the whole area more than ample space to move in inside the sleeve plus lining. 4. Wear the mock up and move around, move your arms to get an idea of where the arm needs more space when articulated. 5. Learn and practice full felled and half felled seams until you are happy with the results 6.use basting double sided tape 6mm to join the seams ready for sewing, the sewing should be the last finishing process to lock all your work up to that point. Most basting tape can be removed after sewing, try to attach the basting tape to hold the seam but not under where the stitch is if at all possible( gums up the needle) 7. Practice where the arm joins the body of the jacket, the arm hole needs to match the jacket arm circumference perfectly, enough seams on both body and sleeve which must match as this is sewn inside out. 8 where the end of the shoulder joins the jacket is a critical area which sets up how the jacket arm will hang, its also an area which needs some strengthening on the inside as the arms will try to pull from here when they hang. Hope this helps someone. Remember your first jacket may not be perfect, but what you will learn is priceless