sojourner999

Members-

Posts

55 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by sojourner999

-

I was the person who bought an old Chandler cu563. it was not a good purchase decision on my part. I was new to purchasing industrial triple feed machines and similarly new to sewing. I was naïve. It was beat up, ridden hard and put away wet. The needle bar had all kinds of slop, stuck on one stitch length, hook tip was broken off. It had so much wear, the table was seriously worn down where the fabric moved over the table. It was really beat up. It sits in a storage unit. I was able to get a genuine Juki 563 with very little usage for $200. Deal of the century for me. aside from being beat up, I did a little fabri-cobbling to install a syncronized binder (khsew) for fabric binding. I had to dremel away a little bit of metal on the feed dog fork so the binding feed dogs could be installed. With the Chandler, a dremel cut through that metal like a hot knife through butter in a half-second. when I did the same on the genuine Juki 563, it took forever and a day, multiple sessions, and lots of sparks and cursing and muttering before I barely had enough dremeled out to fit the feed dogs. that take away for me was that Chinese metal (at that timeframe) is extremely soft compared to a genuine Japanese Juki. I cannot speak to the quality of the machine you are looking at. It may be in great condition and not used too heavily. That said, I would definitely pay less than what I would pay for a genuine Juki 563. personally, unless this is new-old-stock or almost new condition or a couple hundred dollars (no more than. $250), I would pass and wait for a juki. just my 0.02 goos luck.

-

Juki LS-1341 pricing questions (new v used)

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks so much for your reply. It is helpful. -

Hi, My flat beds (consew 206-rb4 and Juki LU-563) working well. Looking to add a cylinder arm. Hobbyist, looking to be jobbyist, then eventually (down the road) strike out on my own. I am in "analysis-paralysis" on a choice for cylinder arm. My needs should not take me past the 3/8" / 135x16/17 needle type machines. I am leaning toward a used Juki LS-1341 instead of a clone (cobra, cowboy, techsew). My leaning is based on the fact that I can easily get juki parts, whereas getting clone parts 10 years down the road does not give me warm and fuzzy feelings. One thing I cannot figure out is why there is such depreciation on used LS-1341. I see new ones for 5K to 5.5K. I have seen multiple used 1341's for 2K to 2.5K. I have a call in to a semi-local dealer that will have some used ones in a couple months. He mentioned $2,495. I just cannot wrap my head around the fact that a coveted cylinder arm Juki would depreciate 50% from new. Especially when flat bed machines do not depreciate anywhere near as much. Anyone have any ideas on this? Is it people trying to pass off a clone as an original juki? 1341 not as good as regular juki? maybe people want more than limited 6mm max stitch length ?? maybe people want the foot height adjustment knob on top that clones have?? juki perceived not good enough compared to clones? ??? I am perplexed. Also, I don't want to spend 2 - 2.5K for what I think is a Juki and get an ali-express machine painted over. Can anyone shed some light on this situation? Thanks!

-

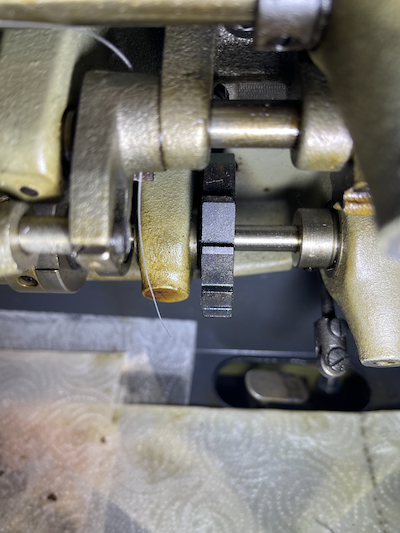

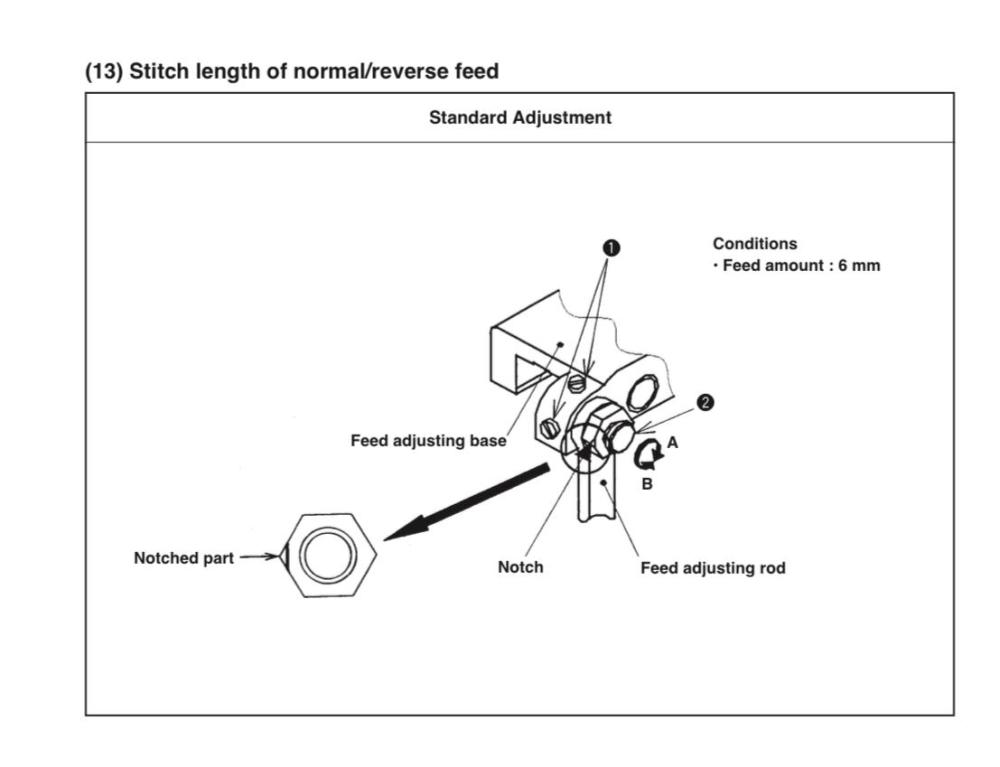

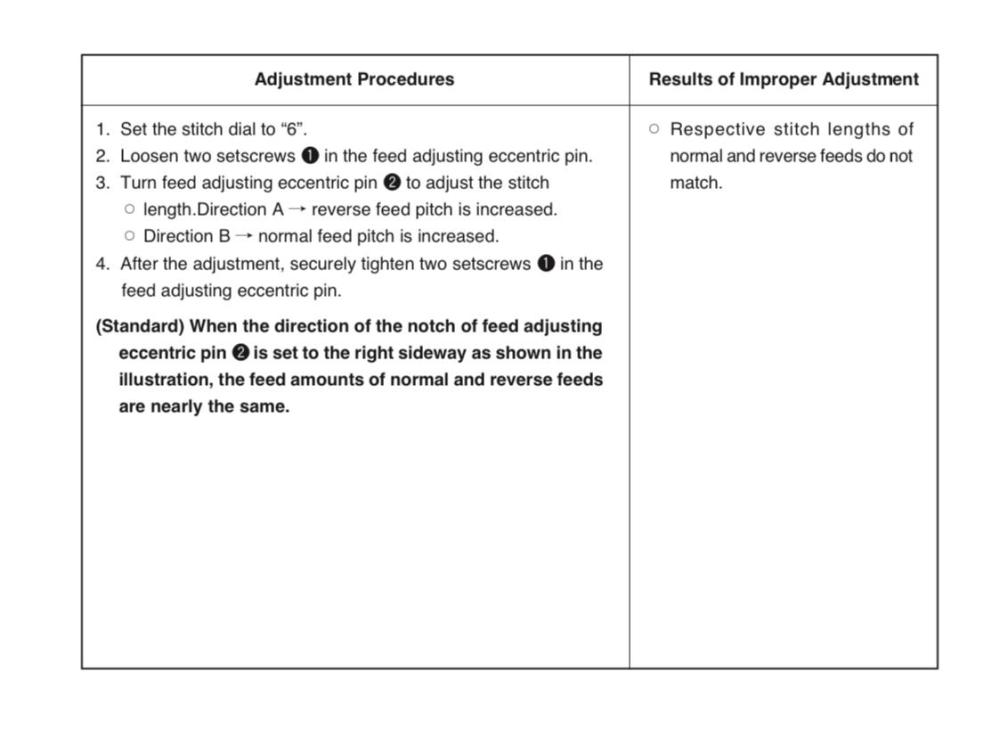

Thanks Bruce. To me, I see that there is support. And your post confirms that, and more. And great to hear that your wife’s machine the fwd and rev holes match. The real disconnect, and uncertainty, I am seeing is the Facebook presence where an authority mentions that the 26 fwd and rev holes do not necessarily match. And some people are turning their material around 180 degrees to have the holes match. And others are manually moving their material to match holes. To me, it is unacceptable for a current production industrial class sewing machine costing over $2K to not have a mechanical adjustment for fwd/rev stitch lengths. I understand that matching may be off if reverse is not started at consistent needle position. And I believe it is up to the operator to be consistent to get consistent stitch lengths. From my call with Dave (I think it was Dave), there is a way to adjust, but I should call him for the first time if/when I need to do that. That’s fine by me. In addition, I really would like to have a manual for reference and to know I can repeat the adjustment. Having that information before plunking down the $$ would alleviate any reluctance on my part. Not trying to be difficult, but I had a bad experience with a consew 206rb-4, which lacked the parts to match stitch lengths. And a juki 563 where I had to knock out a pin that disallowed adjustment. With the juki I can now match stitch lengths, so that is good. Anyway, everyone reading this post probably realizes I ovethink things sometimes. again, thanks for your reply and info.

-

Thanks for the recommendation for the CB-341. I will have to look further if the cobra does not pan out for me. What is compelling for me about the Cobra is that the hook is vertical axis and uses U bobbins (similar to my Juki 563) and that it has lifetime support (sans wear and tear parts). And I can get it with both a speed reducer AND a needle positioner. The cowboy is still in the running for me. I just want to ensure I can adjust for fwd/rev. Thanks for your reply and input.

-

I did call and asked that specifically, with me saying it looked like a juki ls-341 n clone and could the juki engineers manual procedure be used to match fwd/rev stitches. Was told the 26 is a hybrid of juki and Pfaff. Was also told if I had issue, to call and the guy would walk me through matching stitches. On the other hand, my opinion, it appears the FB group, there is mention of not necessarily matching and people seem to be OK with that. It just doesn’t make sense to me to not have an engineers manual available to people who can maintain their own machines. In their defense, I will say there are nice videos available on basic timing, like needle bar height and hook timing. And that there are a few people who are helpful. And that they go above and beyond with after sale support. Maybe the reluctance is because they offer great support and sharing an engineers manual may be opening a can of worms for them. i am really hoping that someone here has the machine and can verify the ability to match stitches and how. Much thanks for your reply.

-

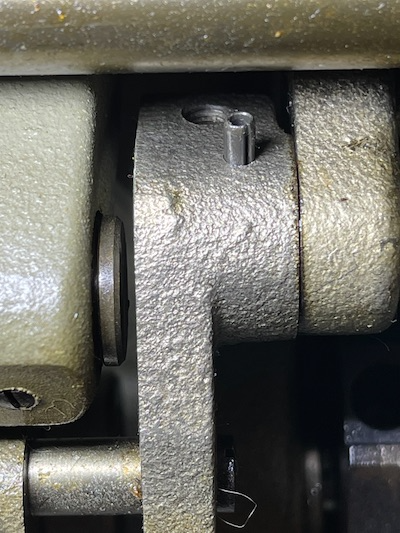

Hi everyone, I am looking at purchasing a cobra class 26 cylinder arm. There are no engineers manuals I can find for the 26. I did find the engineers manual for the Juki ls-341 N here on the forum. And page 14 has the adjustment to match stitch lengths. this topic, 3rd post down, @kgg shared the manuals before I drop my hard earned $$$, I want to ensure that there is an adjustment I can make to have the forward stitch lengths matching the reverse stitch lengths on the 26. I joined the fb group and did not see anything there saying an adjustment is possible, except one commentator mentioning the reverse stitches will not necessarily land in the same holes as fwd. Anyone with a relatively recent cobra class 26 can confirm or deny that there is an adjustment that one can make to match the forward stitches with the reverse stitches? And if so, what would that adjustment be? (My fingers are crossed that it would be the same adjustment as in the Juki la-341n engineers manual p. 14 referenced above). Thanks!

-

I just wanted to share what worked for me. I would never have thought there was a solution unless I had the support of members here and for members youtube videos. Thanks all and special thanks to @Uwe! ----- I still have the Consew 206RB-4 and am getting closer to selling it and getting a Seiko STH-8BLD-3 to replace it. I see that has instructions for matching stitch length. I feel my never ending Odyssey of matching forward and reverse stitch lengths is coming to a close. Now I have to find some light leather to start on my idea (pick pouch for a banjo) and/or tan a hide of the next deer I take (season doesn't start until the fall). Thanks all!

-

Then a couple more punches and it was out. Easy, peasy, lemon squeezy. I guess I have one of the machines where it is easy to remove. I needed a 3/32" roll pin punch (1/16" too small and 1/8" too big). Your mileage may vary. I have no idea how every pinned machine gets pinned. I bought it from Amazon. https://www.amazon.com/dp/B00QV2JTXK?ref=ppx_yo2ov_dt_b_product_details&th=1 tagging @Jhunter13

-

The instructions @1hp provided for consew 206rb-5 are exactly the same as the Seiko sth-8bld-3. They appear to be same exact machines with the former made in China and the latter made in Japan. Looking at the Juki adjustment, i am not sure the Juki “pin” would be as accurate as a screw. And the Seiko/consew looks like the regulator rod would be similar in accuracy. That is just from looking at the images. I am thinking six of one and half-dozen of the other. the Adler 867 looks real nice, but way above my budget at this time (hobbyist looking to eventually move to part time creator). I am going to do some more research and see what I can find. Also, anyone else here with experience may reply in a couple days. Weekend and all. Thanks!

-

Thank you @Uwe. I am going to look at the service manuals for the models I am considering. Sometimes I get “wrapped around the axle” trying to get precision that may or may not be there. I’ll look at the Adler, but that may be out of my price range. Much appreciated. @1hp thanks for the share. Unfortunately, RB4 and prior do not have the parts that R/5 does when it comes to this adjustment. I read a post on here about someone who had success on an RB3 and that did not work for me. I also sent Seiko Japan an email and they responded with an adjustment for a different part. That part does not exist on my RB4. I believe I have exhausted all avenues for this RB4. I am off to find some manuals and do some more research. all - if anyone has real world experience with the models I mentioned, please share. thanks!

-

Hi everyone, I have an older consew 206RB4 where the fwd stitch length does not match the rev stitch length. Furthermore, with this model, there is no ability to match fwd and rev. I also acquired a Juki LU-563, where the adjustment for matching stitch length cannot be done because the part is pinned ( ) I mainly sew textiles, but want to get into leather (deer and maybe elk leather) for pouches or shirts. And I want to have a machine where the fed and rev stitch lengths are consistent at any stitch length. I am looking at purchasing new, either a Seiko sth-8bld-3, Juki 1541s or Juki 1508ns. which of these machines would be the most “accurate” matching fwd and rev stitches at any stitch length setting? Much appreciated for any and all input.

-

thx. sailrite has three smooth feet set. the one i posted earlier, for fabricator and 111 machines one for ultra feed ls https://www.sailrite.com/Smooth-Foot-Set-for-Sailrite-Ultrafeed-LS-1-Leatherwork-Sewing-Machine?gclid=EAIaIQobChMIw5_PwYqIggMV80lHAR15QQRuEAQYAiABEgKIZ_D_BwE and one for ultra feed lsz https://www.sailrite.com/Smooth-Foot-Set-for-Sailrite-Ultrafeed-LSZ-Sewing-Machine?gclid=EAIaIQobChMIw5_PwYqIggMV80lHAR15QQRuEAQYASABEgLH1fD_BwE is it possible that you were referencing one of the other feet/feed dog set? thanks!

-

Hi, I have a consew 206RB-4 and a Juki LU-563. Both have servos and speed reducers. I have yet to enter into fabricating with leather. At this time I have no aspirations to sew very thick leather that would require a more powerful machine. I am looking at using some light weight deer leather to make some small items. I ran across the sailrite smooth leather foot set (link below) and and trying to find out if the foot and feed dog are compatible with either of my machines. Does anyone know if this product is compatible with either of my machines OR if there are any other vendor provided smooth feet and smooth feed dog? https://www.sailrite.com/Leather-Delicate-Foot-Set-for-Sailrite-Fabricator?gclid=CjwKCAjw7c2pBhAZEiwA88pOF4HGGhwCprTbxMNV3ZQ-2UtjNevgkCASoAo6WZ2ya4syTTSttP_1pRoClAcQAvD_BwE i tend to be a gear junkie and would rather purchase smooth feet and feed dog rather than grind and fill standard feed dog and feet. That said, I will grind and fill if it comes to that. I have an email inquiry out to sailrite, but thought someone here may have had experience with this. any help, experience or ancedotes are much appreciated. Thanks!