sojourner999

Members-

Posts

55 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by sojourner999

-

Thank you. @Jhunter13 walked me through this when I was at the sellers property. It is belt drive. I can see the cutout. I line it up with the disk, but it doesn’t appear to catch. I tried holding a screw driver on the disk and was able to turn the hand wheel, so it appears it is not stuck. I just can’t get the stitch length button to catch the indent. Looking at it, from a weird angle, it appears to not be centered in the cutout. Maybe it could also be the button was ground down from improper use? How would you remove and re-install the stitch length button? And if it is not the button being too short, can you recommend how I would adjust the “left/right” of the disk so the button is in line with it? much appreciated,

-

Hello again, Thanks for all the help on the Consew 206-RB4 I acquired previously. Since then, I have added a speed reducer and am very pleased with that machine. That said, I ran across a deal on a Juki LU-563 clone or re-badge. A Chandler Chandsew / CU563. It sewed fwd and reverse. There is a minor hiccup with the button for stitch length selection. It might need replaced or just some oiling. It won't catch in the detent to allow changing stitch length. And it is missing the nose cone? / side plate. Both should be easy fixes. Anyway, after I clean it up, fix the selector and time/setup I am considering using it for purely binding or leather or maybe both. I started looking at Uwe's videos and will work with them when setting up. Does anyone have information on this chandler? meaning is it a re-badge of a juki or a clone made by someone else? Also, can anyone point me to pdf downloads of owners manual, service manual and parts manual? Much appreciated! Tom

-

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks @suzelle! The tri-flow clear synthetic in both bottom and top gear casings. No problems so far, but I am now in the stages of timing machine and replacing some wear parts. So no real sewing per se, just running the machine a little to disburse the oil and grease. I am following 2 - two hour YouTube’s from MTRC Crane on maintaining/setting up the machine. Got stuck earlier today with a stuck screw and @Jhunter13 helped me out with advice to unstick it. So I am back on track. His videos have 18 steps, I am on step 4 now. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks @suzelle! I have and use tri-flow oil and grease in my vintage domestics. I refilled my lower grease box with tri-flow grease. Going to actually open the top grease box and re-fill with tri-flow grease today. I found the right screws to open it up. I am leaning to just using regular Lily White sewing machine oil for the consew. It has been good for others for years and I am reluctant to put some other liquid into where it will go through the wicks. I am not sure how the wicks would react to that. It may be much ado about nothing, but nevertheless, I won’t have to worry about any wick issues with lily white. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

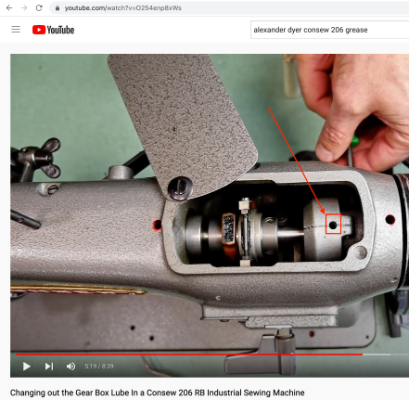

I finally was able to order a bunch of parts for the machine from diamondneedle.com. They had all the parts. I called and spoke with someone there a few hours ago with my order. She confirmed that they were there and they put the order through on a Friday afternoon. Should be here early next week. I am only about 1.5 hours away from their actual place of business. I am going to change the grease in the two "grease boxes" tonight or tomorrow, not sure of the technical name, but that is what I'll call them for now. I watched a youtube from Alexander Dyer https://youtu.be/O254enp8xWs and he goes into replacing the grease, but did not use any grease gun to totally fill the grease box. I have two resized pictures of the "grease boxes". I cannot help but to think that those 2 holes were put there so some type of grease gun could be used to fill with grease. So, my latest question is this, once I change the grease, should I be "squirting" grease into those ports with a "grease gun" to ensure complete filling of the grease boxes? FYI, I plan on using tri-flow clear synthetic grease. And my final question for this post, are there any reason NOT to use tri-flow clear synthetic grease? -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

I did not order parts yet. I came down with a virus that set me back a few days. I plan on getting the machine set up in my work area this weekend before ordering. The bobbin winder looks like I might need to replace it too. And maybe a couple other small parts to have as backup. I want to find all I need before making an order. the 206RB4 takes M bobbins. I think, from smaller to larger, the bobbins are G, M and U. @Jhunter13 has a juki LU-563 clone that takes U bobbins. He may have input for you with his experience on sourcing U bobbins. I did order M bobbins and a set of presser feet from Amazon. The bobbins fit and do not bind when I am hand turning the machine. I have not sewed with them yet. From the seller, it looks like he liked the pre wound bobbin thread. I try to stay away from eBay and sometimes Amazon when it comes to these parts. I wanted to order from sewingpartsonline, but they had some parts back ordered. And with them, it is a guessing game as to when parts will come in. please let me know how your order from diamond needle goes. I’ll be putting an order in soon. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Awesome! The place is a little over an hour away from me, but it does not look like they have a retail presence. Also, minimum $30 order. I am going to call them tomorrow to check on availability of parts I need. good luck! -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

I found diamondneedle.com. They sure do seem to have a plethora of parts, including the ones i need. There is a minimum $30 order. Does anyone have any input, either positive or negative, of ordering from diamondnedle.com ? hx -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

I started the work on the 206RB-4. I took the upper tension assembly apart for cleaning. I found both tension discs has deep grooves where the thread goes through. I figure I would order the discs and a spring too. i went to sewingpartsonline.com, they had discs and a spring, but are on back order. I did a search and could not find individual tension discs. I did find units on Amazon, but the bad reviews made me leery of ordering a complete unit. Any recommendations on a vendor that has quality parts like tension discs and tension spring? Or is this something where I may have to order an entire unit? If so, where to get as close to OEM quality as possible? Much appreciated. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks Wizcrafts! I never even thought if that. Now to ask my wife for some red nail polish. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

New question on the same topic of oiling. Many of the oiling ports, the red paint has partially wore off. I would like to touch up those areas with some type of red paint. Does anyone have recommendations on what paint to use and the procedure for painting those oil ports? Or a reason why I should not do that OR an alternative to red paint? thx! -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Bib Barb looks quite strong and sturdy. Congrats! -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

I was just fixing to try an online resizer and it looks like you may have resized for me. Sorry for any inconvenience. If the external link is still there, I will remove it. Next pics will be resized and uploaded to this site. thanks! -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Pic posted. Do you have any pics to post? Interested in your Consew. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks to @kgg for sharing invaluable input for what I should look out for while purchasing a used industrial. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Here it is. After a test run and pre-purchase inspection (thanks @kgg!), it is now at my house. I couldn’t upload to forum (files too big), so I shared an iCloud album with 3 pics. Any issues seeing the pics, please advise. Consew 206RB-4 TH**** S/N much more to do, clean, oil, buy a servo motor, check timing, buy extra bobbins and thread, get it set up and start sewing. -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Congrats to you! -

Consew 206-RB4 oiling mechanism and sewing speed?

sojourner999 replied to sojourner999's topic in Leather Sewing Machines

Thanks for the info and parts link! The pic of the machine (from the seller) looks good. Doesn’t look worn to me. I am picking it up tomorrow. The person selling it had an automotive upholstery business. He is getting out of the business due to a physical issue. i am excited as it looks good, seems to be a fair deal on it, and it is a made in Japan model. Plus, no need to run at high speed. I’m sure I’ll be filled with questions after I get it and start t9 get it set up for my use. thanks! -

Hi, I have a lead on a consew 206rb-4. Does this model have to be run at high speed to keep it oiled correctly? I understand some models need to be run at high speed. This will be my first industrial and I don’t see myself either wanting to or being able to run it at high speed. Can anyone confirm what type of oiling system this has and if it has to be run at high speed to push the oil through the system? Thanks!