-

Posts

19 -

Joined

-

Last visited

Contact Methods

-

Website URL

Richard-Ferguson.com

Profile Information

-

Location

Ancaster Ontario canada

-

Interests

Outdoors, fishing, hiking, sewing, photography

LW Info

-

Leatherwork Specialty

Wallets

-

Interested in learning about

Sewing, leather wallets

-

How did you find leatherworker.net?

Online

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

TheMortgageGuy's Achievements

Member (2/4)

-

Hello group experts. I moved in July and the movers broke the take up arm on my Juki Lu563. I had a local company repair the machine paid for by the moving company. $730 repair cost. I got the machine back and it doesn’t seem to be sewing properly. hook is too close to the needle, hitting it going forward and appears to be slightly off going in reverse . I spent hours in the past getting this machine to perform flawlessly using help from this forum. Unfortunately the arm that was installed appears to be shorter and does not have the same lift and extension as the original arm did attached is a pic of the new arm installed on the machine I am sure that the old arm at least extended to the front edge of the flange guard to the left of the arm and the new arm does not extend out that far kind of like a Juki lu562 arm and upgrading to a 563 arm when doing a big bobbin conversion am I right ? Is this the wrong arm? thank you richard richardf1969@gmail dot com 9 05 73 00 844 text

-

Durkopp Adler 291 what to look at

TheMortgageGuy replied to Josacraw's topic in Leather Sewing Machines

Does anyone have manual or a video to show how to thread a 291? -

Hello experts with more knowledge than me.. I recently bought a tacsew cg6-6 for my uncle. Cheaper walking foot with top feed bottom feed but no needle feed… great stitches in top and bottom. I had to adjust the hook timing but all good now . The issue is with reverse. my stitch length is 1/3-1/4 the length of the top stitch.. there is no simple fix to correct. I have seen a video where potentially the back plate on the back of the machine behind the stitch length adjuster,,,,there is a a set of adjusters for both forward and reverse stitch length…. Has anyone done this successfully? In a Juki or consew or tacsew?

-

Pfaff 335 H2 complete rebuild thread

TheMortgageGuy replied to Woehlk's topic in Leather Sewing Machines

question.. where did you get your presser feet? are the ones for this machine the same as the Pfaff 335 H3 and newer Pfaff 335? -

Pfaff 335-H3, pfaff 145, rear pivot arm bushings

TheMortgageGuy replied to TheMortgageGuy's topic in Leather Sewing Machines

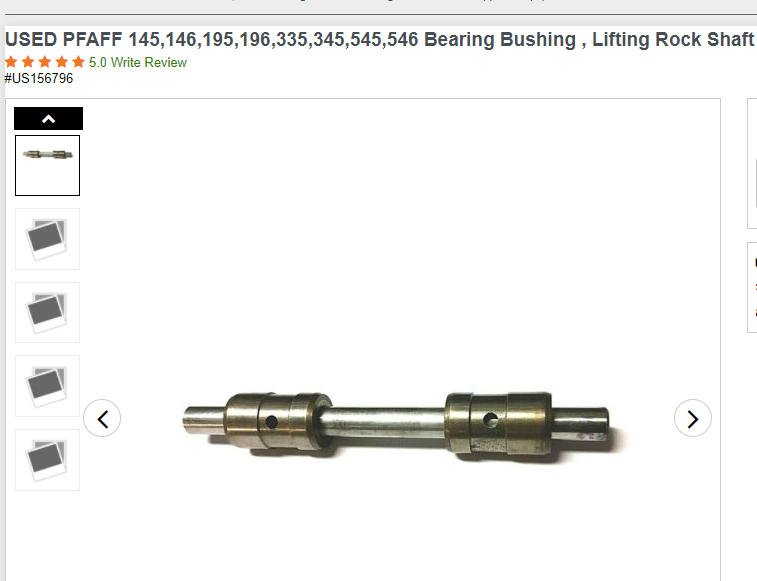

Hello Jimi came to my rescue and sent me a link to a seller that had some bushings in stock.. now ordered... hopefully it works out.. thanks again for the help and support on this forum -

Hello. More work being done on my pfaff 335. I have noticed that the rear arm bushing for the presser arm shaft seem to be very worn. The needle presser foot comes down makes contact with the feed dog but can lift slightly due to play in the upper pivot arm bushings shown in the picture. has anyone replaced these? Can they be ordered? thank you

-

Todd I have a JUKI LU563 walking foot using a servo motor for most work, until recently (New to me Pfaff 335 H3) I am currently looking at a drop-in plate that will accommodate my 3/4 size singer 20U with zig zag... one less table and motor required. the singer will be used for joining sections of leather together or decorative stitches on some of my baseball glove wallets I also have a full size table for a Pfaff 335 H3 but I also just bout an old singer patcher 29K171.. i can mount either one of the cylinder arm machines on that new small table, front left corner (4 bolt holes).. I am waiting for things to warm up and ill move the table into my sewing room The table behind the small one is for my Pfaff 335 H3.. I may swap out its base for the base on my juki.. my juki base is a little rough below is someone else's clone of the singer 20U in a regular industrial table below is someone else's clone (relsew) of the singer 20U in a regular industrial table. I want to make a plate that sit in the original opening and allow the "other machine" to use the same table and motor, maybe different belt. my time i have my 4x8 work table plus a full size table and the half size table... my room is full

-

Jimi I have some questions about the lift assembly my machine that had a efka variostop motor and air solenoids

-

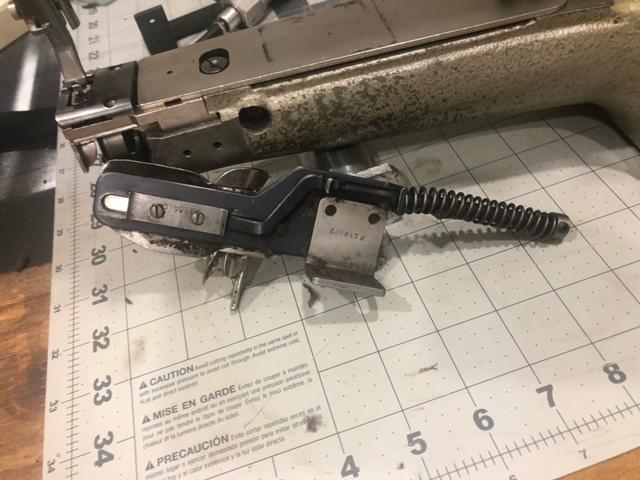

my lifter assembly from the efka variostop system AIR operated lifter vs the factory lifter on the 335 shown below i am trying to find a way to convert what I have to actually lift the presser foot assembly. my "lifter arm" that should be connected to a wire or chain is different that the Original 335 arm (145/545 arm) I also seem to be missing the bracket that would screw on the back and have a horizontal pin allowing the arm to catch the pin and lift the foot up.. the original Pfaff 335 arm and bracket shown in the pic that has the word "MOUNT"

-

Pfaff 335-H3. Broken eccentric, not walking

TheMortgageGuy replied to TheMortgageGuy's topic in Leather Sewing Machines

My picture shows my arm assembly from an air actuated system.. the second pic is from leatherworker.net showing a lifter arm similar to a Pfaff 145/545 and this picture is from a 335 cylinder arm.. has anyone converted a system like mine to work like the original 335? does anyone have a 335 arm (or 145/545) like in the second picture that they want to sell with the bracket/pin unit that I seem to be missing on my unit? -

Pfaff 335-H3. Broken eccentric, not walking

TheMortgageGuy replied to TheMortgageGuy's topic in Leather Sewing Machines

My parts are in and the needle bar assembly is back together..I put on a readily available presser foot, added the bobbin and stitched a couple of stitches manually.. now I am trying to figure out how to convert the old air operated foot lift system to a pedal actuated and how to remove the old knife assembly the motor was an Efka variostop with needle positioner -

Hello Leather Crafters. this may be long-winded.. I cant seem to find topics to answer my questions on the presser foot lift and the Knife removal NOTE: sorry -i did not realize the names of the photos would not show up with the photo a few weeks ago I posted about my needle bar issue. I received the new needle bar rocker and have the machine put back together and I have more questions. My machine was used for binding pics attached for the binding setup (binder 1,2,3) does anyone want to buy this? binder So lets start with image 12 and image 11 : On image 11 you can see a double set of arms. the tall T arm in the back seems have been(previously) connected to a solenoid to release pressure on the thread tensioner.. NO matter if this is pulled from the skinny cable going down through the base or the manual foot lift is used, there is nothing to push the pin in and release the pressure on the front tensioner. Image 10 shows the pin and metal slider, The slider does not really even touch the pin when the manula foot lift or the T-arm is moved.. maybe something is missing On image 12, the long arm (outside arm)pivots on the center (pivot point) and has an adjustable arm(black skinny shaft) that lifts up on the tension release mechanism but does nothing to lift the presser foot. in image 11 you can see the black metal bracket that was bolted to the (Long foot lifter arm) and had a solenoid attached to the back of the machine(covering the round hole so when the solenoid was activated, it pushed down the arm to lift the foot...I think.. but there is nothing on the presser foot side that would lift the linkage for the presser foot image 9 shows the solenoid that was inside the head (round hole area) under the arm of the machine is the solenoid that was on the back cover over the round hole.. The body of the solenoid was attached to the cover plate and when activated would push down to activate the long arm and I believe there should have been something else connected to lift the presser foot up ================================= second set of pics are the Knife assembly at the Rotary hook area and under the base (Black brackets inside in pics (0,1,2,6,7,8) has anyone removed the knife assembly from a machine? how do you do it.. ========================================= lastly:

-

Pfaff 335-H2 Presser Foot Feed Issues

TheMortgageGuy replied to subgirl's topic in Leather Sewing Machines

Did you get this fixed? Was it the needle bar rocker shaft being out of time? -

Pfaff 335-H3. Broken eccentric, not walking

TheMortgageGuy replied to TheMortgageGuy's topic in Leather Sewing Machines

The tip is wedged into the square slider… I tried a hammer an punch and then heated it up with a torch to try and tap out the tip that broke off and is stuck in the square piece. ☹️ I spent $52 usd plus $30 shipping for the two separate pieces -

Pfaff 335-H3. Broken eccentric, not walking

TheMortgageGuy replied to TheMortgageGuy's topic in Leather Sewing Machines

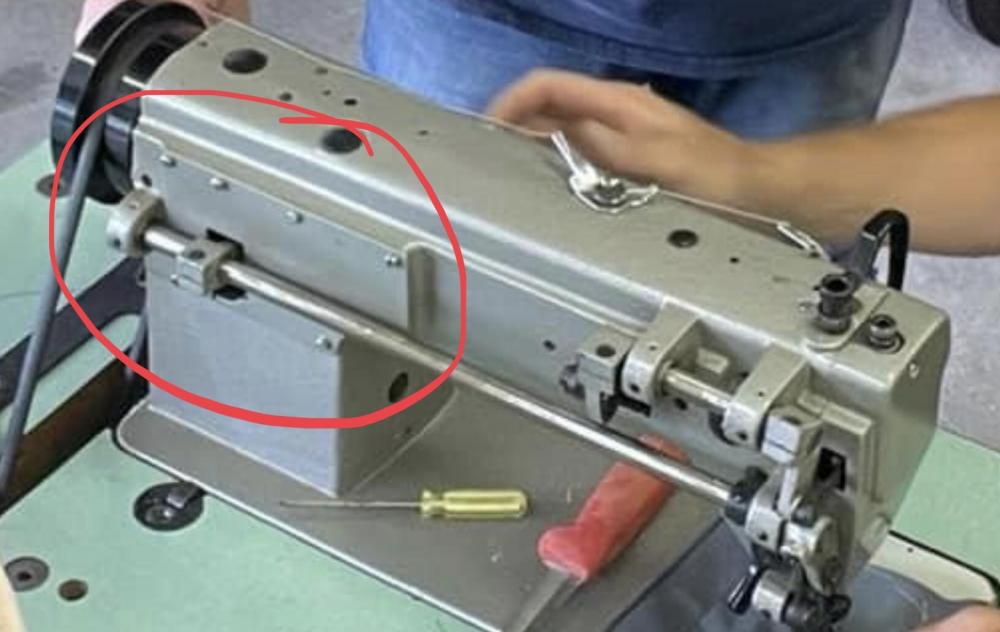

I found some parts on EBAY from lithuania and poland The last pic with the red circle shows the part that broke off the needle bar rocker/ needle bar frame shaft The first part was ordered as well because the tip from the needle bar rocker arm is stuck inside Parts ordered.... If anyone else has spares of these two items locally, please let me know