milkman

Members-

Posts

28 -

Joined

-

Last visited

LW Info

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

milkman's Achievements

Member (2/4)

-

Thank you! What model do you have?

-

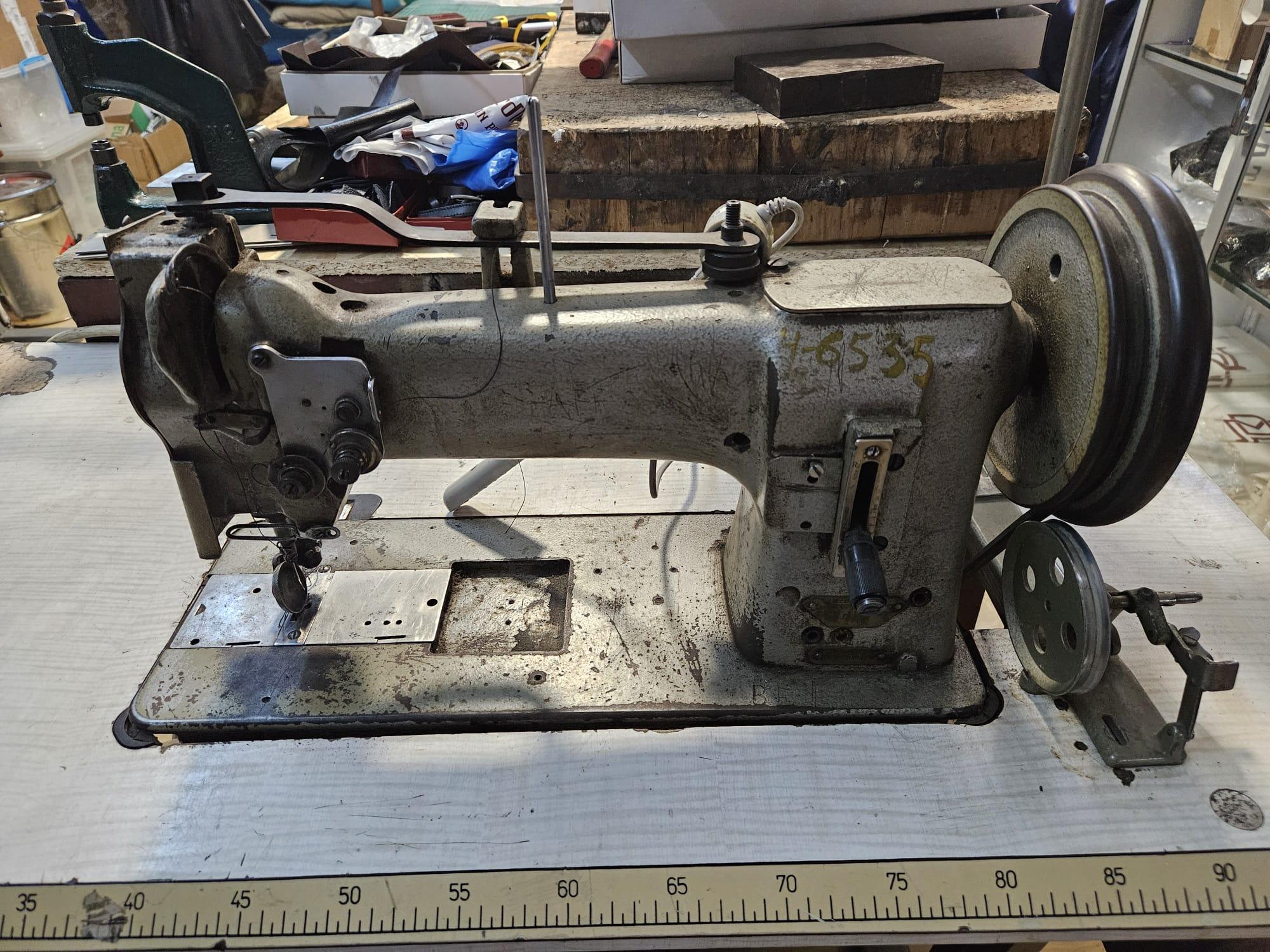

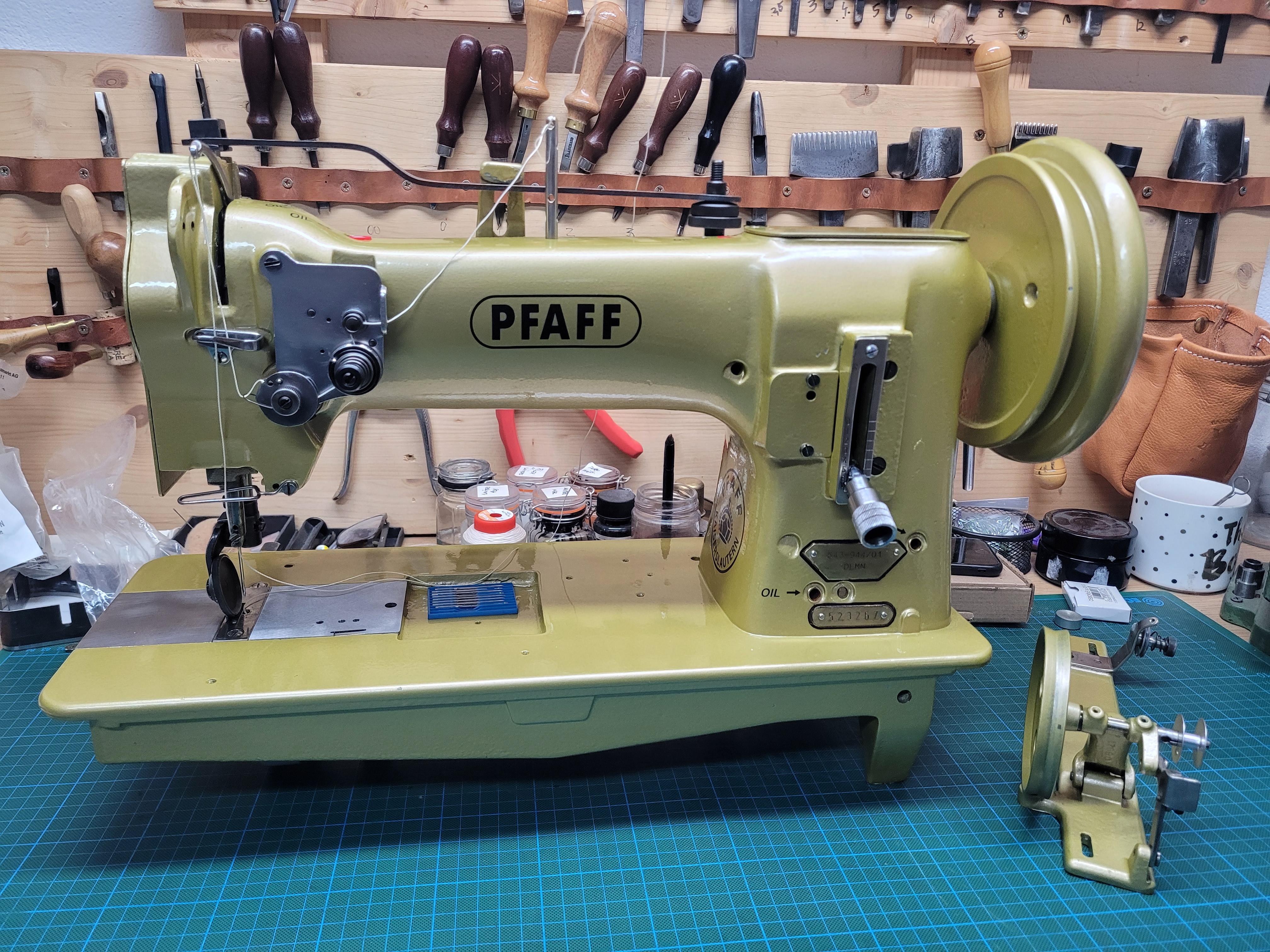

Thanks! I did a bit of paint chipping when I assembled the parts but that's for the patina...intentionally LOL. One thing I forgot mentioning in case somebody wants to add the needle feed. Timing between feed dog and needle is different in both cases. Drop feed = feed dog moves when the needle is out, dual feed= they go together. I want to see also what does it mean to add a larger feed dog, as surface. Such as one from pfaff 142 with dual needles. Because with its original feed dog on 543, the one which is offset to the needle, it feeds ok, but since the needlepushes down there is a small bit of movement on the material. So my intention is to use a dual needle feed dog so the presser wheel sits on the feed dog but also the needle to have some support underneath. In theory it should work. A 545 would solve each issue but since I already have the machine and honestly it stiches really nice. In the video, ticket 15 thread or v207 size up and down and VR 150(edit: needle is S cut in the video, checked today) size needle. I like VR compared to LR due to 2 more extra cuts. I've added a pic with how the machine looked before. A bit like crap. And I must say the parts are really durable. In terms of age, I dated based on the serial number, in 1955.

-

Thanks! Decals are from https://www.singerdecals.com/ I found the majority of parts in my country, Romania. And the 545 parts for the needle feed, I found them on ebay in Poland. https://www.ebay.com/sch/i.html?item=305456329419&rt=nc&_trksid=p4429486.m3561.l161211&_ssn=jerzmerci0 But there is also another guy in Lithuania: https://www.ebay.com/str/sewtech71 I would have loved to buy a 545 but it was over my budget so this 543 I bought it for nothing actually and in my budget, still, I could buy the parts to restore it. Honestly I really like working on these machines. My Adler got the same treatment and now I am having a second Adler 169 that I want to prepare for a buddy of mine.

-

I ve found it locally in Romania. At a mechanic

-

Found it! How can I close the topic? Thanks

-

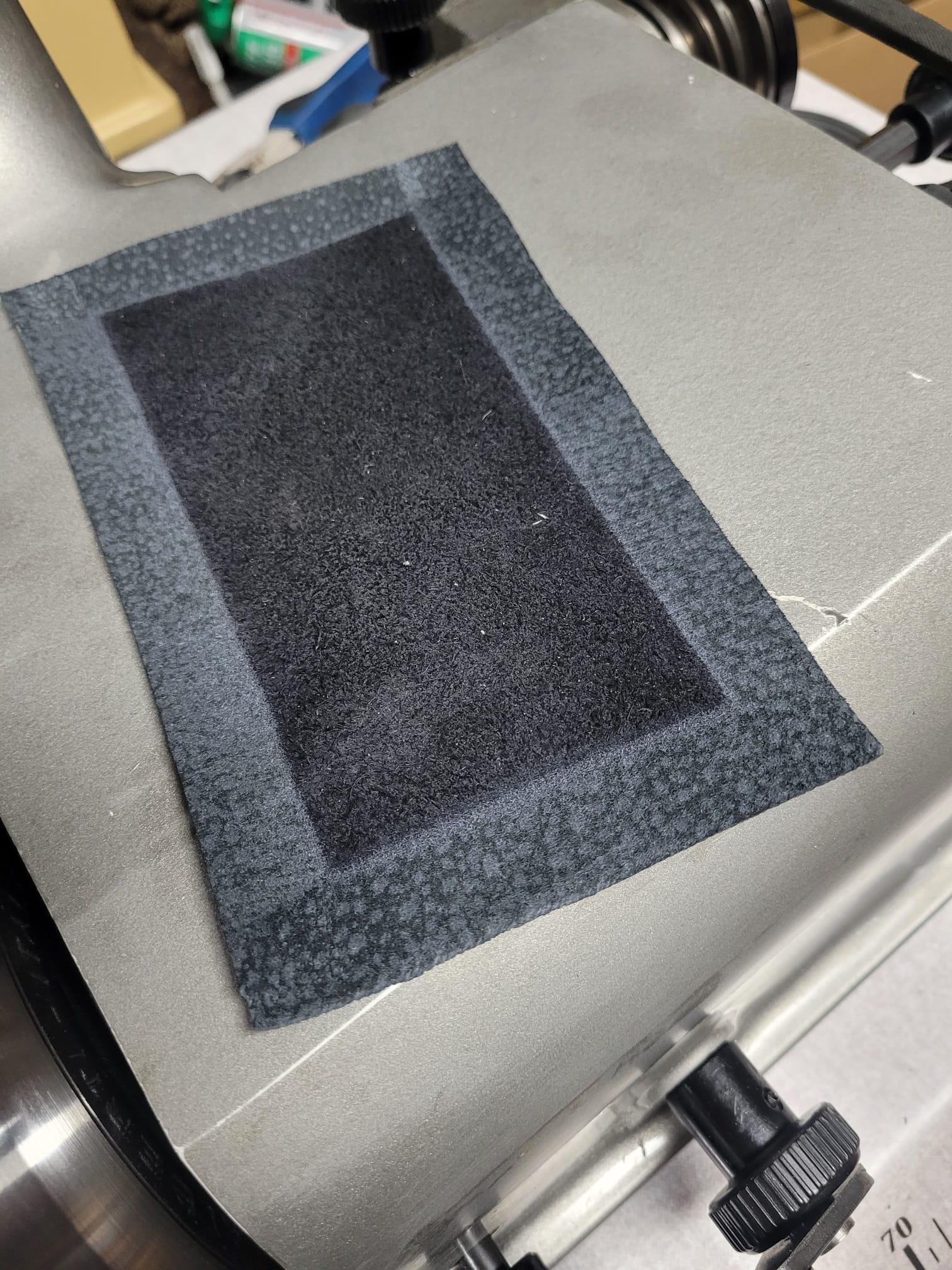

Hi guys, In case anybody needs this info. On my 543 DLMN, I ve added needle feed. I made sure the bushings are there, and then you only need the needle frame rocking shaft and its linkages to the forward movement shaft,parts from a 545 and to increase the slot in the needle plate. My issue was that with the rubber coated feed dog and presser, the machine couldn't feed oily leather. Now it works beautifully. https://youtube.com/shorts/rnloVTpOTMM?si=CJgy8PEpiT6QMeQO Probably same scenario can be applied to Pfaff 143. The machine was completely rebuilt by me at the beginning and it is stitching beautifully my belts and notebook covers. It can handle thick threads, upper and bobbin, compared to my 169 Adler. Pics are from the rebuild. The parts for the needle feed were added after everything was assembled. A bit of planning needed but it went ok! Cheers, M.

-

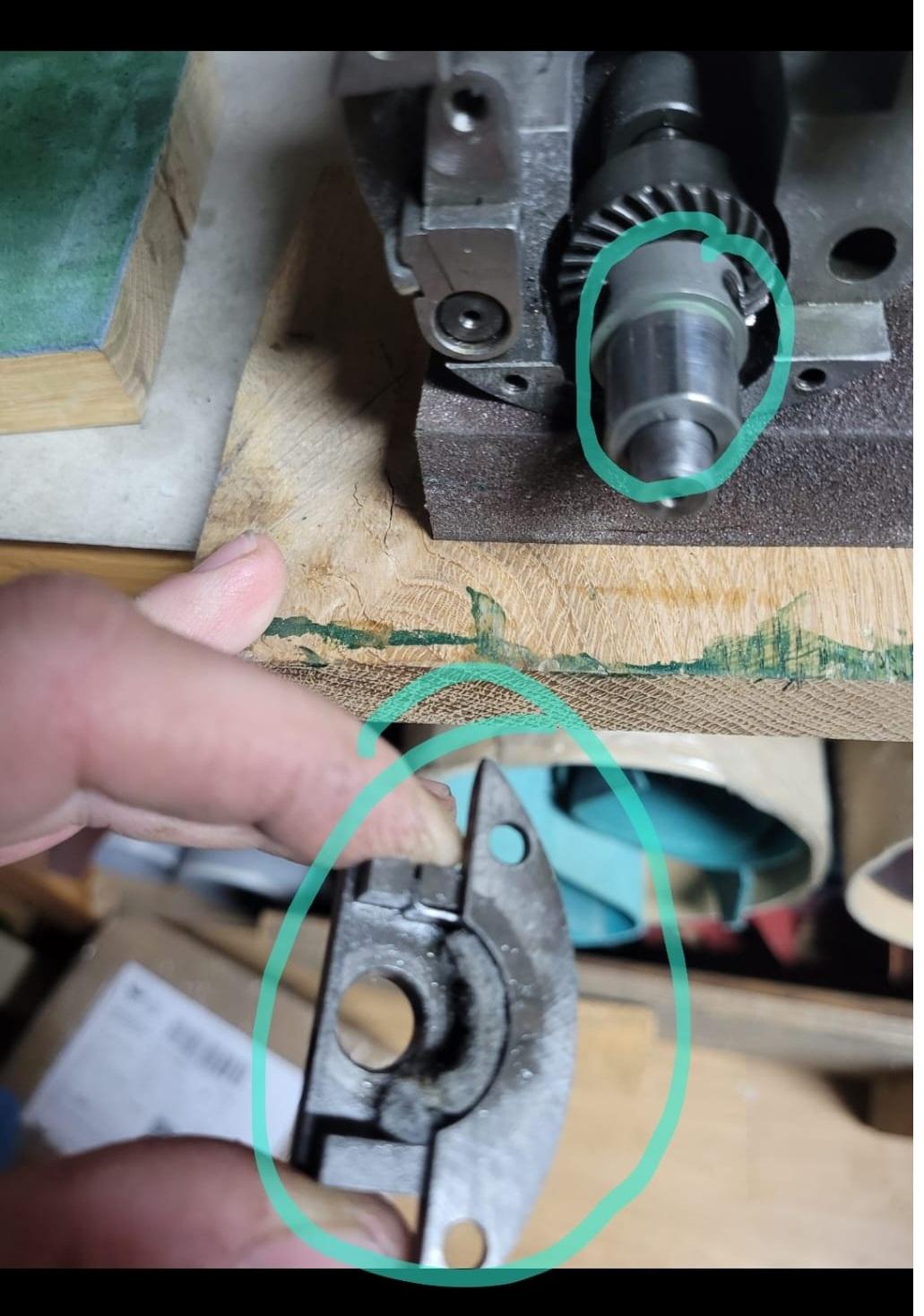

Hello everybody, I am looking for the feed dog eccentric and the end support for the hook shaft. For an Adler 169. I am guessing that the parts are similar for Adler 269. Attached photo. On this second 169 I have, the machine was initially equipped for binding so it lacked the eccentric. So the end support of the hook shaft is thicker compared to the one for up and down movement. I can let this part go if somebody is interested. I can buy the parts from DA, new. But they cost a small fortune. So I thought asking around here, maybe somebody has them and can sell them cheaper...maybe. Thank you!!! M.

-

If somebody needs parts for the Pfaff 138-6. I can disassemble it and send it to you. Machine is complete. I also have the handle and the stitch step scale and the gear covers are there i can let everything go for 80 eur plus shipping. Machine is in working condifion

-

Hi guys. I bought this machine for myself but honestly my space it s getting very small with it inside. I already have a FAV2 from the 80's that I rebuild myself and that s without a vacuum so takes little space. I prepared it like I do for my machines... Anyway, regarding the ad. Price is 1200 eur, excl shipping. from Romania. But I can arrange the transport inside the EU aprox for 250 eur. Machine model is FAV2 MA from 2007. Rebuilt by me with original FAV parts. And cleaned the table and drawers. The machine features a separate motor for the grinding device which is really awesome because it sharpens the knife so nice! The only thing that it "has" : the transport roller shaft, where the clutch is was shortened/grinded by the prev owner to have the clutch engaged all times - which is so stupid because you can actually use a screw that locks that in place. Anyways, in order to make it work again, I just used a washer in the clutch cap, where the clutch disc is, so I can compensate for that difference. In terms of function, it doesn t have any issue like this. VIDEO: What I replaced: - replaced all of the bearings except the oscillating one inside the transport shaft. That one is fine. - the cardan shaft - the articulated shaft that connects the gears to the roll. The older one was done - new transport roll and its shaft - new FAV knife with new grinding stone ofc - new gears - new grinder belt and new transmission belts. - new presser foot - new grinding device shaft, the one where the grinding stone is attached to - new rubber coupling . The piece that connects the knife shaft to the pulley Like I said everything works like new and skives really really nice. It comes with its manual and a thickness caliper and a scrap ejector rod made by me Machine is 380V but if you need to I can prepare it for 220v but the VFD s are on your expense...those cost quite a bit.

-

The service manual.is gold! The german one for who speaks/understands or google translates is even better. I fully reconditioned my machine, painted it and found an original Adler table which I reconditioned it as well. Waiting for some needle plate and feet, but it sews perfectly. Attached a pic from.when I was doing the timing of the feet and needle.

-

Thanks!! 69 class, makes sense...similar stitch length lever. Now it s clear for me. just to adjust the cam where the fork goes until I have no movement. Fingers crossed! By the way, do you loctite all the screws you open after making adjustments? Allright, I will assemble everything and oil everything again and try to rotate by hand and I will post an update.

-

Hi, I ve started reconditioning a Adler 169. The machine didn't had oil for a long time so rotating it by hand was very hard I disassembled the feet and needle linkages completely and cleaned them but haven't yet assembled the parts. I ve also disengaged the timing belt. The machine is still rotating hard. Then oiled it a lot and started rotating. It seems to improve a bit. Question 1 : timing belt disengaged and only upper shaft, the hand wheel makes about 2-3 full rotations when letting it go after giving it some momentum. Based on your experience is this in spec or should I look into the cleaning of bushings...if I ll be able somehow to remove the upper shaft. Question 2: does somebody know the nominal distance between the presser fot bar and walking foot bar in 0 position for the stitch adjustment? The issue is that setting the stitch length to 0, the walking motion was still there. Not sure if I understood correctly after browsing the forums, but this can be adjusted from the connection of the rocking arm shaft and the other linkages found inside near the stitch adjuster, and this can be fixed by knowing this standard distance between the feet bars. Thank you!

-

Yup, it is sold! Thanks

-

Adler 167 - Timing Belt Replacement

milkman replied to Constabulary's topic in Leather Sewing Machines

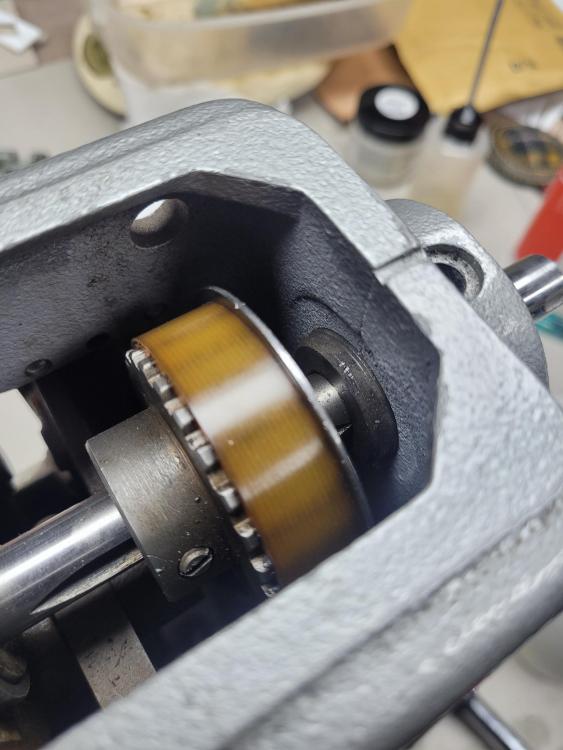

Reviving this topic. What is the worst that can happen? I seee that the bearing is mounted from the inside probably after the last owner replaced the transmission belt. Also the belt is not wide enough and it pushed the upper axle to the left side, needle side, so I moved a bit the sprocket to not have that movement. Adler 169 Edit: the lower shaft, feed dog with the eccentric, had also a left right movement. Not sure if I had to eliminate that movement. Unscrewed the lower transmission sprocket, pushed the shaft to the right and tightened the sprocket. Rotated the machine by hand. Looks normal to me. -

It s as good as sold. Thanks for looking

.jpeg.e4e7a9501f229793c202ae69a1173ae1.jpeg)

.jpeg.9f1677283bacae864e5bf55d8c4a8c31.jpeg)

.jpeg.209c2a4e77f6bd9216aa41a1c5523e7e.jpeg)

.jpeg.041f554a3936cfaca83d6591ee69f226.jpeg)

.jpeg.62476addf24d37d6ec13c1a6247cbeb3.jpeg)

.jpeg.293d6a4b06548f9ec1fcc36e042ff0b3.jpeg)

.jpeg.c4dd47a5911dc7355f5788d695983c30.jpeg)

.jpeg.84bc5afdaa530da2842082c6c25d4fec.jpeg)