Southerngunner

Members-

Posts

119 -

Joined

-

Last visited

About Southerngunner

- Birthday 05/22/1953

Profile Information

-

Gender

Male

-

Location

Yucca Arizona

-

Interests

Family, Silver Labrador's,guns

LW Info

-

Leatherwork Specialty

Still trying to figure that one out.

-

Interested in learning about

The proper way to use sewing machines and work leather

-

How did you find leatherworker.net?

On google Researching old Singer 168w101 machine

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Southerngunner's Achievements

Member (2/4)

-

Pfaff 145-H4 6/1c LMNP or Consew 206RB

Southerngunner replied to shinny's topic in Leather Sewing Machines

I have no experience with the Pfaff but I do have a Consew 206 rb-2 that is a fantastic machine. I set mine up with a servo motor and different pulleys to slow it down it is capable of sewing 3/8" veg tan with no issues. The Pfaff has a great reputation and either machine would be a good choice. I would suggest that you take some leather and test them both if possible, then choose the one that impress's you most. Good luck -

Consew 255 RB? tensioner issues

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks Bob , It looks like it will be a pain in the butt to install but I'll holler at you and get one coming this way Thanks for your help Terry -

Consew 255 RB? tensioner issues

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

I tried that several times and it doesnt move at all when engaging the lift. Where might be the best place to order one , and are they different between the 1 or 2 models since I'm not sure if mine is a 255-1 or 2 -

Consew 255 RB? tensioner issues

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

I would but I broke my pin stretcher last week gosh dang it. -

Consew 255 RB? tensioner issues

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

That's a great idea, It's raining like cats and dog's here so when I can get down to my shop I will try it and update, Thanks -

Consew 255 RB? tensioner issues

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

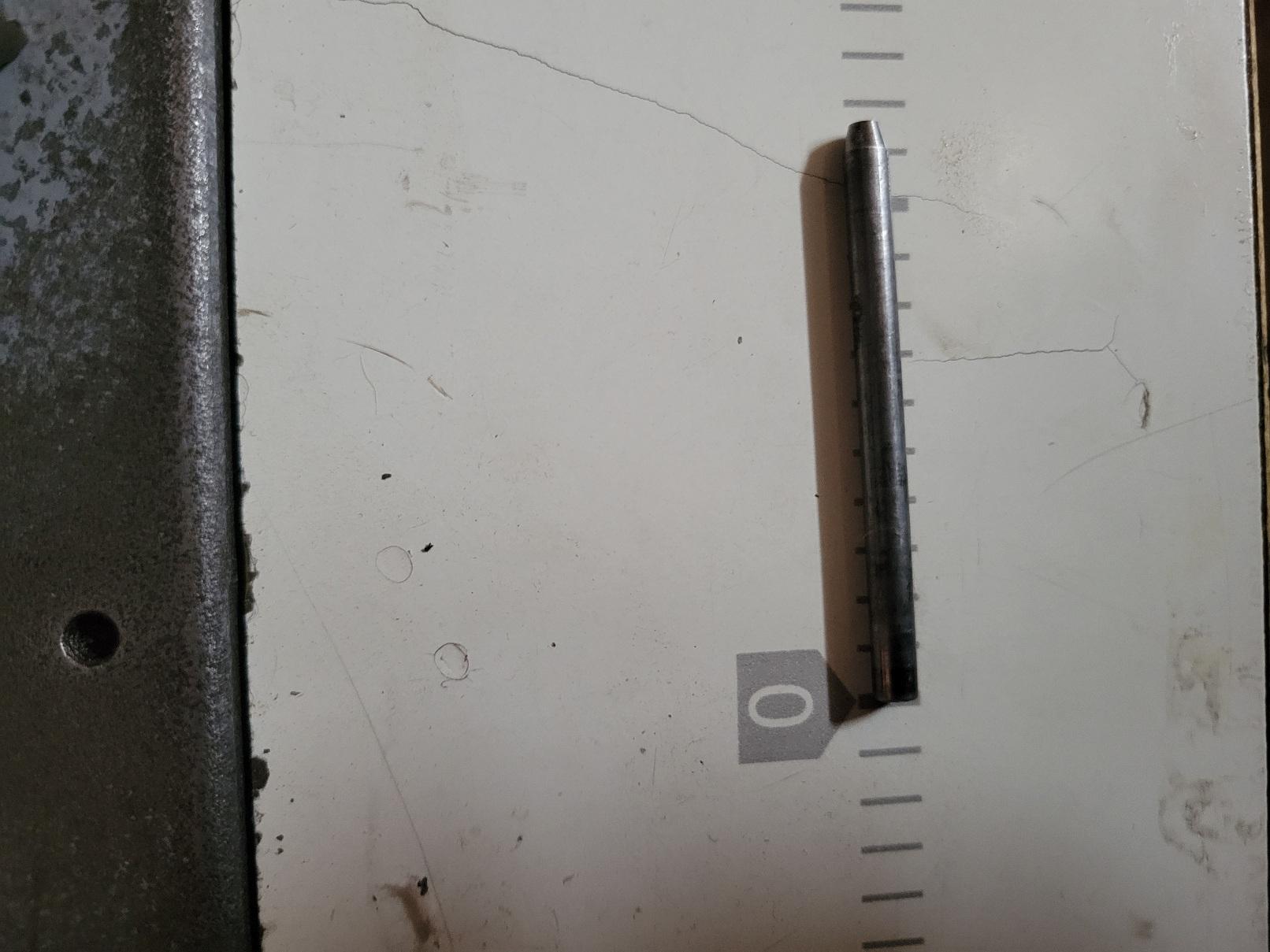

-

I bought a used Consew255 rb a while ago and after trying to set it up there was several issues. It had been painted and was filthy inside , I ordered a new feed dog, plate , needle bar and thread tensioner. I finally got around to cleaning and oiling everything to make sure everything was moving freely. When raising the presser foot it do not release the tensioner. I got the release pin freed up and was able to get it out of the hole. It doesn't move when the presser foot lever is raised to engage the paddle on the new tensioner, I could really use some guidance on this if anyone has the time. I took a picture of the serial number as there is no tag designating model One or Two. I also include a picture of the release pin. Thanks, Terry

-

Old Ruby treadle machine

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

I can't wait for the leather drive belts to get here so I can really run it the way it is supposed to be. I still can't believe it's 144 years old and totally functional, I can't help but wonder if my Class 26 will hold up that long. -

Old Ruby treadle machine

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

AlZilla, thanks for the tip on the needle, there is not many options in my area for picking up parts and supplies. The only sewing machine shop that I used relocated 70 miles away. The idea about the magnet is a keeper. -

Old Ruby treadle machine

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

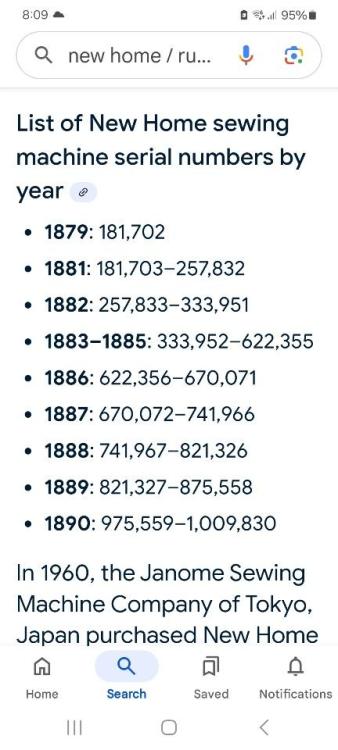

Thanks for everyone's replies so far. Wiz your assessment means a lot as I went into this one blind but lucky. I knew the price I paid was well worth it if just for the cabinet and treadle , the shape of the machine was a huge bonus. I found this list of New Home machine dates and if I'm reading it right this old gal was made in 1881. regards to all , Terry -

Old Ruby treadle machine

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks for the info they are really cool old machines, these are the only needles that I have that would fit. At first it wouldn't pick up the bobbin thread so I cheated it down a lttle in the clamp and it seems to work ok. Can you tell me where I can order some 20x1 size needles? -

Old Ruby treadle machine

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks for your reply, I'm still trying to find out how old but I'm betting it's over 100 . I ordered some belts and extra bobbins that should be here next week. Regards, Terry -

This old gal was on craiglist and the guy said his lady wanted it gone. They never tried to sew with it ,but every thing moved freely and it appeared to be complete. I ended up giving him $20.00 for it and figured I would have a conversation piece at the least. I'm not sure when it was made but the serial #is R231636 if any of you has an approximate mfg. date I would appreciate any info. Ruby was produced by New Home machines, I found a couple youtube videos and figured out how to thread it and make some stiches. I oiled it and did very little cleaning as it all was in fantastic shape. I didn’t know what area to post this because I know it is not a leather machine per say even though it will sew lighter material. It did not have a belt but I was able to sew by turning the handwheel. I didn't expect much for $20.00 but I am very happy so far. Opinions and comments are welcome

-

Very nice, you always knock it out of the park.

-

possible adoption of a consew 255 r b

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

My new/used 255 rb showed up undamaged and other than needing a good cleaning in good shape. I did a quick clean and oiling and stuck it on the table to see if it worked at all before tearing into it. I was pleasantly surprised it stitched fine top and bottom with 138 thread with a 22 needle, the stitches were very small and it was hard adjusting but I did get it to change slightly. I am having a problem with the top thread fraying and breaking. Also the presser feet was very low ,under a 1/4". Any advice is welcome and appreciated. Terry