Metalhorseman

Members-

Posts

34 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Los Angeles CA

-

Interests

Carpenter Trade, Hobbist Metal Fab/welder, Off-roader, Camping

LW Info

-

Leatherwork Specialty

None yet

-

How did you find leatherworker.net?

Searching on web for info on machine

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Metalhorseman's Achievements

Member (2/4)

-

Ohhh . Some one snatched it up before I got there !😔 Dam should have went Friday when I first found . Dam dam dam probably never see one of those again in my life span. Thanks guys for all the info

-

Still can’t find manual that shows pic of machine .. what do you think that bar in vertical position on back of machine is ? I’m not sure why I can’t see pic in manuals that I found , I’ll keep looking thanks guys , if anyone comes across manual with pics could u post please so I can see . Maybe I’m really computer illiterate.😕

-

Thanks Constabulary ! Do you know if uses 135x16,135x17 needles ? One of the first things I found said machine uses 16x74 and is a obsolete needle system, then it says 16x2 and 16x1 is the modern equivalent and another AI mode thing said 135x17 is same needle system as 16x2 system ,so that gets me confused . Hope to find manual to study before I drive 50miles to see. Traffic here is no joke 😩

-

Hi everyone, came across this machine Singer 17u123 , just the Head is available, but can’t find out much about it? Looking to purchase but need to find out what and if needles and bobbins are available . I wanna sew light leather stuff and Canvas with it . Need manual to make sure machines all there. Sorry still struggling with adding pics . Don’t wanna buy another boat anchor. Also only thing comes up for manual is a 17-23 ,, and I can’t retrieve/open to see machine .. very odd . Thanks for all info .!!. Metalhorseman

-

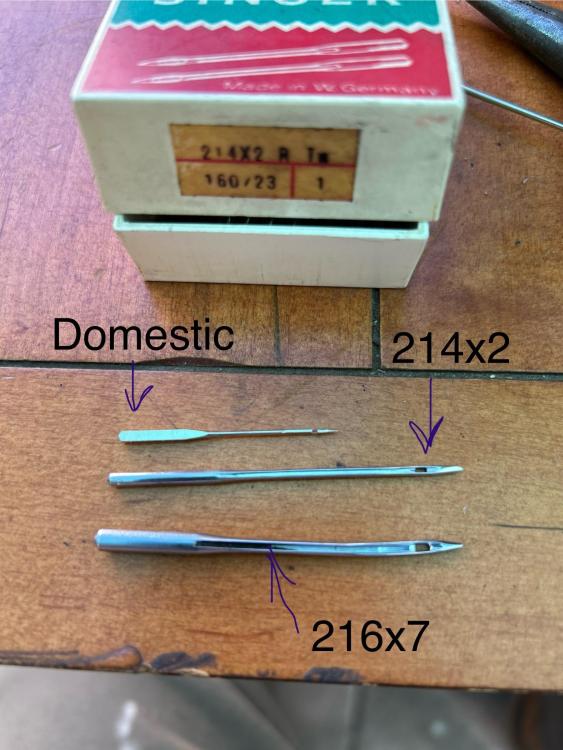

Hello everyone! I’m back been busy with other things . Is there anyone that would sell me a couple needles for this machine . I’m thinking I’m going to sell machine I really don’t have any use for the thing. I just don’t want to spend a bunch of money on it. I’m in over my head already. Needle size is 216x7 or Equivalent’s that I found on web are CYX7 , SY 5021 and CANU 50:44 MA Bob , Thank you for all the info, but I can’t spend $200 on a bunch of needles I won’t use . If I find a buyer , I will definitely tell him or her to contact you regarding changing needle bar to run smaller needles. Thanks in advance to anyone that can help.. Wayne

-

Sorry should read “DonInReno....”

-

Hi Bob , that sounds like a good option . But not to sound like a long winded knucklehead, I need some instruction on going about changing needle bar and setting up to sew or “Darn” with smaller needle bar , I noticed mine has two lines on needle bar , I’m guessing for setting bar height . Maybe I can get more replies on a few more questions before ordering the needle bar and clamp from ya . Do all machines needle bar height set up the same ? I recall ”DODINRENO “ explaining this to someone before ,maybe I should send message to him and “Constabulary “ who has similar machines to get more insight. I’m still trying to learn how to use website and post pics , gets kinda confusing for this 60yr old ..lol Thanks Bob

-

On thread exchange web site 216x7 is also called CYx7 I’m new to this , so I’ve never heard this,, more googling.. Thanks Constabulary Ok , trying to figure out this picture posting gig .. I put pic in wrong spot now …

-

On thread exchange web site 216x7 is also called CYx7 I’m new to this , so I’ve never heard this,, more googling.. Thanks Constabulary

-

Hi ! Yes on Darning machine ... I have a box of 214x2 also on label it says 160/23 these are way to small of a shank . Your saying 214/238 is the class of needle ? Or are you saying 2 different needle classes?I’ll google that .Thanks Also I looked in your profile about your machines,,they take class 214 needles u say .gosh wish I could post pictures ! I’ll keep trying to resize also found needle info on “ The Thread exchange” trying to decifer compared sizes

-

Hello everyone ! Happy Holidays! Well I have another question for y’all. I’ve had this 133k18 machine for awhile , never used it until last week .l put a new belt on it and got it running,went and removed needle to micrometer to find some smaller needles and put back in and must not have tightened needle screw enough and it slipped out some and bent after using it for 5 minutes . And I only had one needle for machine. Having a hard time finding this needle , it’s a 216x7 class . It’s a huge needle maybe size 26 .. I would like to find smaller needles maybe 18-22 in size . Anyone use this machine ?. I wonder if it’s possible to change needle bar to a 135x17 like my other walking feet machines ? I’ll switch tinkering to another newly acquired machine 111w155, while I wait to hear from you guys. This sewing machine stuff is addictive! Thank you to all in advance also also will try to post pictures in a bit from my iPhone ,was challenging last time I tried .

-

Speed Reducer Mount made from Clutch Motor Mount

Metalhorseman replied to Constabulary's topic in Leather Sewing Machines

Great idea ! Got to go look in my yard ! -

Hi kgg On my Seiko STH-8BLD-3,, stock hand wheel ,60mm pulley on Fesm 550,3450rpm servo. Dial for rpm set at 650 ,it has one more click to 350 , but motor doesn't work in that position. Any suggestions on how to make that work at lowest rpm? I ordered a 45mm pulley should be here next week. Did a dog collar, 3 layers of polyester webbing and noticed machine kinda struggling to get up and go ,that's when I started reading about heavier handwheel and larger pulley on the handwheel with smallest 45mm servo pulley. Looked into speed reducer box but won't fit under table because of T-table cross brace is 6 3/4" below motor. Also liked box style for easy tilting back Head.But not in budget at the moment. I just bought a Juki LU-562 with reverse and bought a servo, I think that has a 45mm pulley on motor and to keep at girlfriends house for awhile to do some awning projects. Thought the older handwheel trick with the built in larger diameter pulley would be a less expensive way of going now,found on web for $45 plus price of belt. I am very mechanical inclined and would like to try this on the Juki. Also have talked to other member here about installing 6" sheave/Pulley on head to slow it down a bit. I think that would be slow enough. Someone mentioned more weight on upper pulley for better punching power thru thicker material also . Please read what Gregg from Keystone was talking about . Sad he passed away .I had bought my Seiko from him.

-

Heavier and larger pulley on this Handwheel ! I found a cross reference number for that pulley .# 241688 came up and maybe was on a Singer 51w52, 53,55,56,57 and a 57w model .. still need to do more research on how it bolts on or slides right on with set screws. Any info on subject would b e appreciated. Thank You