KillDevilBill

Members-

Posts

61 -

Joined

-

Last visited

Contact Methods

-

Website URL

None

Profile Information

-

Gender

Male

-

Location

Youngstown, Ohio

-

Interests

Camping, fishing, of course leather

LW Info

-

Leatherwork Specialty

Holsters and sheaths

-

Interested in learning about

All of it!

-

How did you find leatherworker.net?

Google machine

Recent Profile Visitors

1,058 profile views

KillDevilBill's Achievements

Member (2/4)

-

That's what I'm thinking, but don't have all the details.

-

-

I think I got it figured out. Needs a little tweaking, not crazy about the buckle but pretty happy with the results. Pattern is available for free if anyone needs it.

-

Don't know about Ferg, but I'd definitely be interested!

-

I just bought a kangaroo hide. Wow. Although a little pricey, this is going to be a game changer for my wallets! Great stuff, and I haven't even used it yet!

-

Has anyone had experience making watch fob straps? Seems pretty straightforward, just a mini belt. I'm confusing myself thinking about how they're folded, and where all the holes go. I'm also wondering if/how to get fancy with them, not much room for tooling. Suggestions on leather type?

-

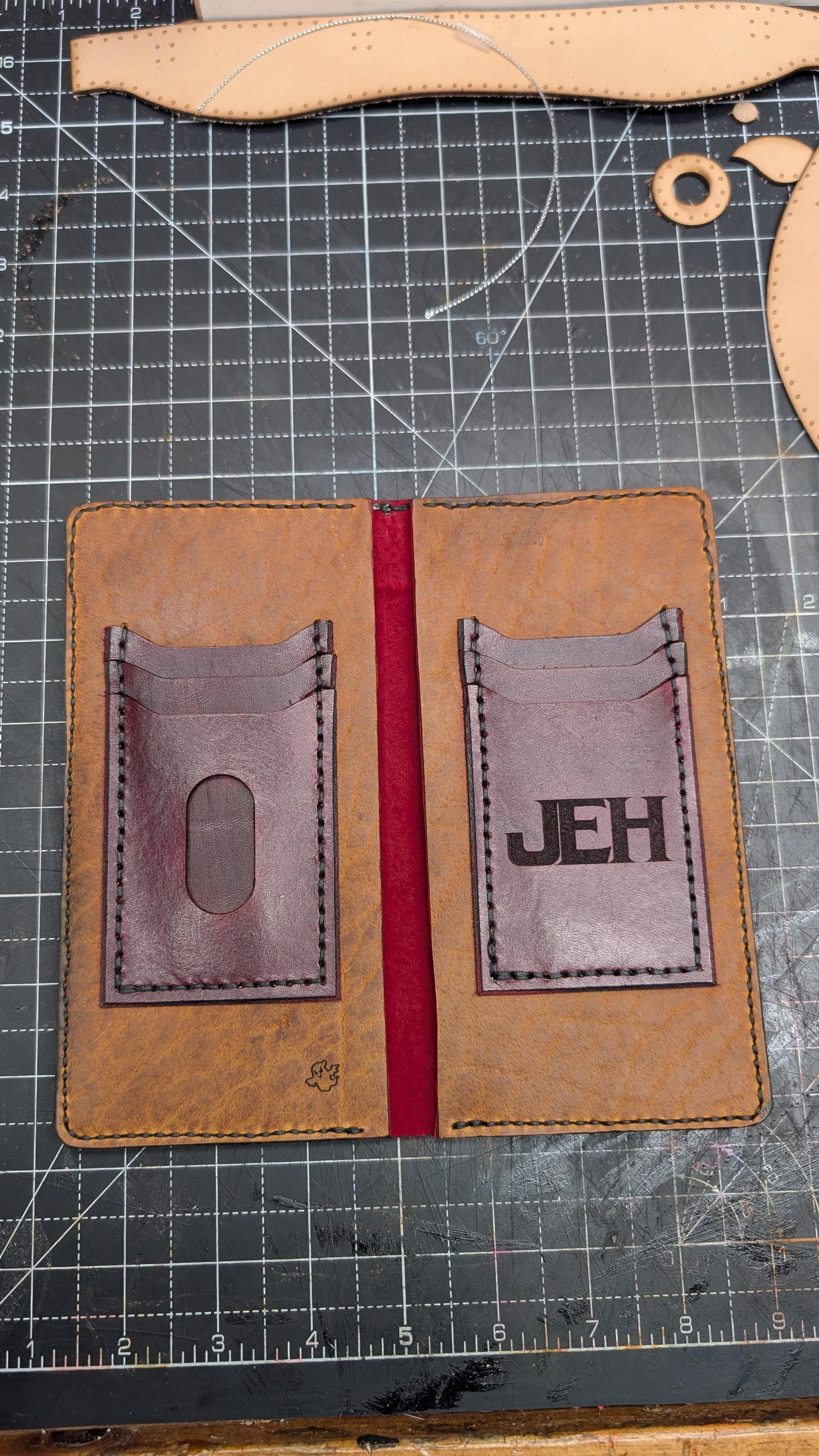

Decided to update/upgrade my own wallet. My own design, version 2.0 Hand tooled, hand stitched as always. Was trying to make it look like an old tractor with the dye/paint. Didn't come out like I had it pictured in my brainus, but I'm happy with it. Questions and comments are always welcome.

-

I've been seeing a LOT of these "minimalist" wallets. Screenshot added for reference. Not my style, I'd probably never build one, but how in the hell do they make them so thin? I'm obviously doing something wrong because my wallets are fat. Well, comfortably plump. This is 4 layers in the pic, and it looks like barely 1/8" thick. I understand it's pretty thin leather, but is there a certain way to cut the pockets? On the edge of the stack, it only appears to be 1 or 2 layers thick. I'm listening.... Learn me something. Lol

-

This was one of those "hurry up on Christmas morning" projects. New wallet for my mother-in-law. I was terrified of tooling the hummingbird, so I kept putting it off, until I couldn't any longer. I need to learn how to add card slots without making the wallet so darn thick. I see wallets with 6 card slots that look great. I haven't figured that out yet. 4/5 veg tan outer with real gator accent, pig suede lining, "peanut" bison dividers, 2/3 veg tan pockets. Bismark brown dye, black acrylic antiquing.

-

This is pretty cool. Blade shape alone makes that one a challenge. Looks great!

-

This is fantastic. Nicely done!

-

New sheath

KillDevilBill replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Knife is in Washington State, I'm in Ohio I honestly thought about more of a bevel, have a new unused beveler.... I was afraid to screw it up. -

Customer wanted something budget friendly and not too fancy. Part of a gift to his father. He made the knife, asked me to make the sheath. I found out that both he and his father are veterans of the 82nd Airborne. This is the first sheath I've made without having the actual knife. Customer took very nice precise measurements, and good clean photos of the knife. I really like the natural grain on the front. Can't see it in the pics, but the antiquing laid down in there nicely. I just hope the dang thing fits!

-

Thank you!

-

Finished up a phone holster, came up with a good idea by accident. Kinda put the logo a bit too high, didn't want the strap to cover it, so I flipped it over and secured it to the back. So now I have an "ejector strap" which works out kinda nice!

.thumb.jpg.7b83907b17613afe0cdc856f1257806a.jpg)