Search the Community

Showing results for tags 'comparison'.

-

I’m trying to decide which machine to buy between a Brother LS2-B837 and a Juki LU-562. I’m not going to be using them for extremely heavy work and they are both available to me in good working condition for around $800. The Juki seems to get a lot of praises as a reliable workhorse but it’s older than the brother, has a smaller bobbin and seems a little harder to adjust the stitch length. I’ve read that changing the stitch length on the Juki can sometimes require timing adjustments. if anyone has a good working knowledge of these two machines your input would be appreciated.

- 4 replies

-

- brother ls2-b837

- juki lu-562

-

(and 1 more)

Tagged with:

-

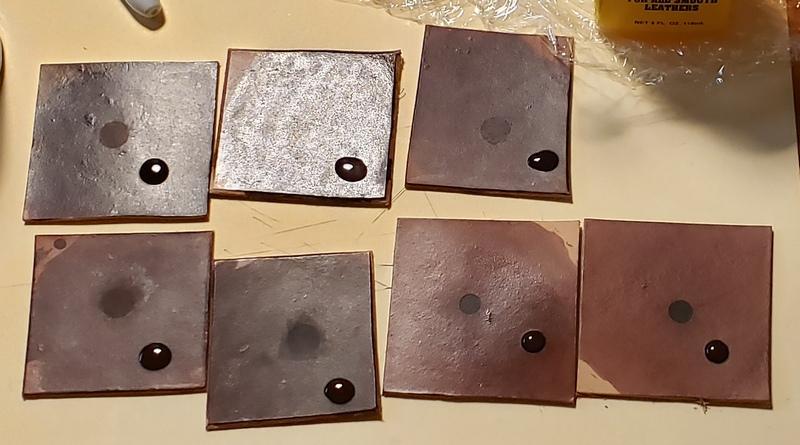

Yesterday, I tested seven different finishes. These were applied over Fiebing’s Pro Mahogany. I was looking for: color change, level of gloss, flesh burnishing and waterproofing qualities. This report is not super organized and may contain errors but I think it conveys the basic results of my tests. I do not wish to spend more time to perfect it because it was a casual test anyway. I put two drops of water on each sample. After one minute, I wiped off one drop of water and let the other sit until it was completely absorbed (over an hour or two). I wanted to know the short term and long term water resistance of these products. When the samples were completely dry, I buffed them in attempt to “repair” them as much as possible, without re-treating them. Buffing did slightly improve their appearance. The damage actually came in the form of cratering. It appeared that the solution had evaporated completely off of the sample. The edge was easy to see and feel. The crater was approximately 1/20 of a millimeter deep. Resolene won the water test. It was completely waterproof. I had a thick coat on there. The color change was quite dramatic but Tan Kote was even more so. Tan Kote was second best. The one minute test showed damage only if the light was reflected off of it in just the right angle. The long term test was a little bit easier to detect but not too bad. Tan Kote resulted in the deepest color change. Shocking, actually. Very dark brown. Satin Shene was a surprising third. The short test did show a very slight discoloration and some loss in gloss. You could tell there was some damage but it was minimal. Color change was very significant. Gum Tragacanth and Tokonole were tied. More damage on both areas than Satin Shene. Sno Seal and Shoe Polish were by far the worst. I must qualify this by saying that I did not warm the leather, nor use multiple coats. I smeared on one coat, rubbed it in and buffed it off. The water damage on these looked like they had burned with a cigarette or like acid had eaten into them. Satin Shene, Tokonole and Gum Tragacanth were the easiest to work with and they all resulted in a very similar semi-gloss finish. Resolene and Tan Kote were sticky and impossible to apply smoothly with a dauber. An air brush would be a much better method of application for these two products. BTW, I did not thin them for this test. I know that is protocol but I am lazy. Both have superior water resistance to the other products tested. Tan Kote can be applied with a dauber and then quickly spread with a finger to smooth it out. This actually resulted in a nice smooth finish that was second in gloss to Resolene, and significantly glossier than the others. If for some odd reason, I could only have one product for flesh burnishing and top coat, Satin Shene, Tokonole and Gum Tragacanth would all work but I would go with Satin Shene, because it had slightly better short term water resistance and it was the best of all the products for burnishing the flesh side. I do not consider this testing to be definitive in any way as it was not scientific and I may get different results if done on different leather on a different day. nick Top row: Tan Kote, Resolene, Tokonole Bottom row: Gum Tragacanth, Satin Shene, Neutral Shoe Polish, Sno Seal

-

Hello, So, I've been wanting to SEE a good comparison between Hermann Oak and Wickett & Craig, there is a lot of people somewhat DESCRIBING the differences (or lack thereof), but I have not found anyone having actually documented it with photos/video. So, I received some swatches from W&C the other day, and decided I'd upload some pictures for reference. I have been only using Grade A Hermann Oak (yes, true Grade A). I was excited to hear that Wickett & Craig's tooling leather is lighter in color, and that they have no minimums straight from the tannery! I have to say, though; I am a little concerned with the flesh side quality of the swatch I received. The big thing I've taken away from HO's Grade A tooling leather is that the flesh side is always very tight and the fibers seem to be very short and consistent across the back. I was hoping that would be the case for Wickett & Craig's top grade leather, but the quality isn't quite the same for the flesh side. The flesh side of the W&C tooling swatch seems to be looser, the fibers seem to be a bit longer and inconsistent. Not a HUGE difference, but a difference, nonetheless. Now, I wrote the sales manager regarding the quality, assuming that the swatches that they used were just from scraps and aren't of their "Standard" or "Top grade" quality. The response I received was this: "The flesh will not be a problem Zayne. I'm sure it is just where they clicked the swatch?" Im not exactly sure that means, but I'm assuming it has something to do with them cutting out the swatch with a press, and it just doesn't seem like thats what would have caused the flesh side to be the way that it is. Anyway, have a look at the photos I uploaded. Again, I don't know for sure if the tooling swatch W&C sent me is factually top grade, but the sales manager didn't say that it was or wasn't when I asked him, hence the response. So, I'm assuming that the swatch I was sent IS their top grade, unless one of you can prove me wrong! In one of the pictures, I included the flesh side of the "Oak Skirting" swatch I was sent with all the other swatches from W&C. The flesh side of this one really scares me. It reminds me of the first cheap side of leather I purchased from Tandy. I'm really hoping this isn't W&C's "Standard" quality. Please prove me wrong! P.S.- I am in no way trying to throw shade at Wickett & Craig, I actually do prefer the lighter color of their tooling leather compared to Hermann Oaks. I'm really just looking to provide some information and hopefully gain some insight in return.