Search the Community

Showing results for tags 'industrial sewing machines'.

-

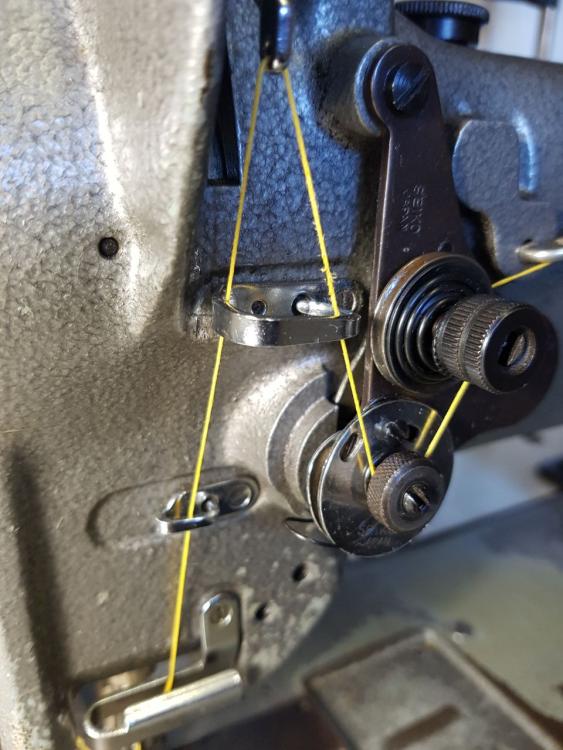

HI, I am hoping to get some help with my Consew 226R. I have had it for a few weeks, purchased from an ex upholsterer. It was very dirty and some parts were not attached, so i have been cleaning it up, putting it back together and ordering the odd screw, spring etc online to replace things. I now have it sewing and operational, however I just can't get the thread tension right. I thread it up according to the manual (and according to the amazingly helpful youtube videos that I've found). But what happens it that the thread seems to be too loose when the needle comes up and then the thread jumps off the thread controller disc, out of the spring and then wraps itself around the back of the thread controller nut, or sometimes the back of the thread controller itself. I have tried various settings by turning the thread controller more to the left or more to the right, I have tightened the spring, moved the spring stop up or down - and I just can't crack it. I pulled to whole tension bracket set up apart and checked each component, and everything 'seems' to be working as it should. I have read posts on this forum referring to worn pins behind the bracket, but it's difficult to tell if this is worn, with nothing to compare to it too. Also, even on the few occasions where the thread does stay inside the thread controller for a while, the thread ends up breaking because it seems to get stuck up inside the tension discs and then it just breaks down at the needle. I got this machine quite cheap and I'm now feeling very frustrated that it won't even sew for 10cm without something going wrong. I'm really hoping there is something simple I've missed. Really appreciate any help offered that will save me going to a sewing machine mechanic just yet (will be my last resort due to finances) - and I can see that there are many experience users on this site. Carrie.

- 27 replies

-

HI Folks - I have a Singer 96-16 industrial machine and I am in need of some sewing machine repair help - any one out there have experience with this machine or know someone who does repairs to this type of machine? Thanks Paula

- 13 replies

-

- industrial sewing machines

- sewing machine repair

-

(and 1 more)

Tagged with:

-

Hello all, Many thanks to member and mentor Uwe Grosse for telling me about this awesome web community! I love my new/old Pfaff 1245 706/47 (see photos). Cosmetically, it looks like a low-hour machine. I see no evidence that it was ever repainted. When I got the machine, the heavy-steel knee lifter bracket was bent slightly and not installed, so I straightened and re-installed it, and it works fine now. This made me think the machine may have been dropped at one time, although I see no other evidence of damage on the machine. The table looks like a newer one, so I think it has been replaced (clutch motor works fine). The oil drip pan and collection bottle were missing, so I have ordered those. The machine came with only a generic 6 mm piping presser foot set, which seemed to fit correctly. I tried to mount a set of Kwon Hing standard feet, but the outer foot shank on the Kwok Hing set was a bit too narrow (about 2.6 mm wide). The shank opening on the outer foot bar on my machine measures about 3 mm wide. I have since ordered another generic 5 mm piping foot set, and when they arrived, they fit my machine’s outer foot bar. So I ordered some more generic presser feet sets which I will need for the seats in my car, as well as some system 190 Schmetz needles in both “R” and “D” points, but they haven’t arrived yet. At Uwe’s suggestion, I checked my needle plate and feed dog part numbers, and they are correct parts for this subclass model. The needle currently mounted on the machine reads “Schmetz (symbol) 130,” so I don’t know if the “130” refers to the size, or if it is the wrong needle system. Being anxious to test it out, I did some practice sewing on scrap vinyl with Sungard 138 thread. So far, I have noticed two issues: The stitch length control responds to different settings, but the length of stitches produced is shorter than the size indicated on the lever scale. The longest stitch produced is only about 4 mm. The machine seems to sew pretty well in the forward direction, however, when reverse stitching, the stitches become loose and messy-looking on the bottom. I have tired all sorts of tension adjustments, both on the top tension and bobbin case, as well as re-threading the machine per the diagram, but I can’t eliminate this issue. There is a mechanical snapping sound at higher tension settings, too, and I don’t know if this is normal or not (I don’t think it is normal?). I have the parts manual, user manual, subclass publication, and at Uwe's suggestion in another forum post, I purchased and downloaded the CORRECT service manual for my machine here: http://sewingonline.co.uk/library/pfaff-service-245-to-1246.html I haven’t gotten a chance to go through the adjustment procedures outlined in the manual yet, so I am hoping that will resolve my issues. Although these specific issues are not directly addressed in the service manual, I suppose that making all of the factory-recommended tuning and adjustments would be the best way to proceed. Meanwhile, I was hoping some Pfaff experts out there are able to give me some advice on what I should be looking for to get these issues resolved. Thanks in advance for your help! Kind regards, Tim

- 3 replies

-

- short stitch legnth

- loose stitches in reverse

- (and 2 more)