Search the Community

Showing results for tags 'techsew 5100'.

-

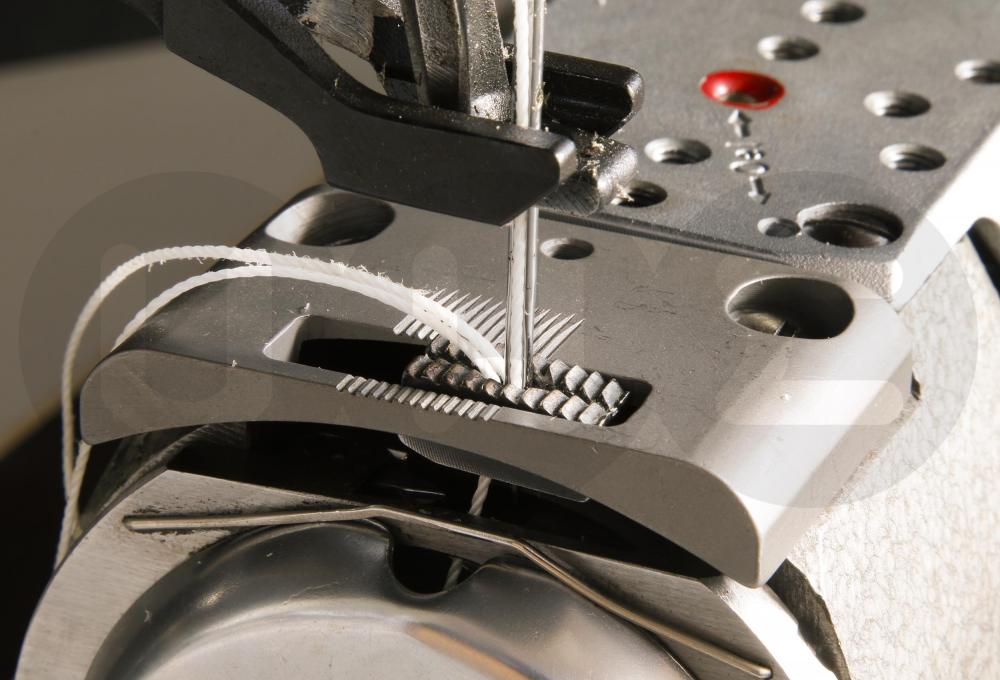

This post I have done to assist buyers of the narrow needle plate sets we developed here in Australia for the Cowboy CB4500, Cowboy CB3500, and most other 441 clone machines including the Techsew 5100, and Cobra Class 4. Many of these machine owners have now purchased these sets and couple have reported back some rubbing issues when changing over to the new plate. In most cases their machines are set up well but occasionally some machines over time get a little out of ideal alignment with how either the needle centres into the fee dog or the feed dog locates into the needle plate. These instructions should help for any needle plate feed dog relationship alignment issues on these machines, whether it is for the standard needle plate feed dog set or our Narrow needle plate combination set. For those of you that have not seen the narrow needle plate set in use and what they can do you can see some here in this video link - https://youtu.be/a83lCJe4JKo or this one - https://youtu.be/wdloxyjeB1w You can see more on these plates in this earlier post I made here - The next video I will do is to show the drop down guide for these machines and how easily they can be installed and why they can be a better choice. Follow my Channel if you want to catch more like it.

- 9 replies

-

- cowboy cb3500

- cowboy cb 4500

-

(and 3 more)

Tagged with:

-

I have some flat-top harness maker throat plates that work with the feed dog in place and fit both Adler 205 and Juki TSC-441 class machines. I call them UTP205HM for the Adlers and UTP441HM for the 441 class of machines. They're the exact same plate. The naming difference stems from the fact that I just recently discovered that they also work on the 441 machines. The price is $59 and includes shipping within the U.S. For international buyers, please look in my Ebay store (http://stores.ebay.com/uwe) in the "Throat Plates and Feed Dogs" section. Ebay's Global Shipping Program (GSP) handles all the shipping and customs details and is actually cheaper than I can ship things directly. On the Adler 205-370 (and clones) you can use your original throat plate mounting screws. For use on 441 class machines, I'll include two small washers for under the screws (the 441 throat plate screws have a smaller head and a different thread pitch). I hope to find a source soon for screws that will work on 441 class machines without a washer. I have a limited number of these plates on hand and won't be able to order more once they're gone. I acquired them as part of a larger inventory purchase and I don't actually know who made these plates. Here's the throat plate mounted on an Adler 205-370 (UTP205HM): This picture shows the throat plate mounted on a Cowboy 4500 (UTP441HM):

- 12 replies

-

- adler 205

- juki tsc-441

-

(and 3 more)

Tagged with:

-

Hi all, I'm wondering what the max thread thickness is for the cowboy 4500 type machines. I know they are rated at 415 max thread, but has anyone successfully used a thicker thread? Also wondering about the make up of the thread. The usual thread is twisted 3 strand nylon or polyester. Has anyone tried braided thread like the Tiger Ritza or maybe even artificial sinew, I guess the split fibres might be a bit tricky with this option. thanks Nick

- 4 replies

-

- cobra class 4

- cowboy 4500

-

(and 1 more)

Tagged with:

-

Hi, I’m a new member on here trying to learn and looking for sound advice based on the 100’s of year of combined leather work experience on here. So, please, let me tell a little about my story…… So, my mother, who is has been an exceptionally gifted craft person and artist for many decades (been a teacher, collaborated on books and won awards in different, intricate, craft fields), lost my father last year after caring for him for many years through an all too common illness. The whole process drained her and drained her financial resources. She’s asked me to come up with a way, since I setup run my own marketing business, for her to make a modest living so she can still have a decent retirement. After much thought, thinking about her skills and personality (her obsessive perfectionism!) I thought leather craft would offer the best opportunity to do something she would enjoy, be likely to be good at, and that I could comfortably develop as a small business for her, here in the UK. She is also a mandolin player and singer in a local band and her friends are all musicians, and because of this, we settled on her making instrument straps for guitars, mandolins, brass etc. We are lucky enough to live within 30mins of a leather craft shop. We went and got some veg-tan scraps and some cheap tools for a few pounds to see if she would like the medium. She instantly loved the feel of working with leather and started noticing all kinds of cross-over techniques from her past craft experience. She is very enthused about the whole thing and she has decided she is serious about letting me help her create a little business for herself. She wants to get the right tools to work with the best leathers she can get so she can make really strong, high quality products. So, she’s the skill but I’m the research and planning! That is why I’m here…. SEWING MACHINES!!!!!!!!!!!!!!!! I’ve read the 8 page guide on here started by Wiz about how to select the right sewing machine for the job at hand. That was one hell of a read in one sitting, but it did help me understand that I was probably looking at a triple feed, walking foot with servo motor and I would be best served by going for a dedicated leather sewing machine than a upgraded domestic or a cross-over industrial. Feel free to correct me! Thank you to all that made that thread the informative read that it was. I’m personally of the opinion that the most expensive machine that I will ever buy would be the cheap machine that won’t do the job, i.e. a total waste of time and money. Especially since I am using my mother’s capital, I am eager to make sure we acquire the best quality machine for the job without making a mistake and buying a product that has more features than we would use. I don’t believe I can source a true leather sewing machine in the UK. After a 400 mile round trip to see the country’s largest industrial sewing machine showroom, they just tried to sell me something that I don’t believe was fit for purpose and was over budget. Their so called expert was getting prompted by me, and I’m a total novice!!! Sourcing from the States it is then! Since I’ll be paying 20% of the cost of the item in import tax and then about $400-$700 shipping to the UK (so over $1000 more than the list price of the machine), and waiting over a month to get it to the UK where I will have to hire a truck to go and pick it up from a port or airport I really, really, really don’t want to pick the wrong one! It’s going to cost a lot, take time and effort to get it here and setup in my mother’s workshop. _______________ We will mainly be sewing straps using heavy bridal leather with a thinner suede or leather backing. Some of the designs we intend to produce might require a double layer of the bridal with backing, but I wouldn't anticipate any thinker than that. 80% of the work would be the single layer of bridal with the backing. We may occasionally use snake skin or alligator hide in the mix. I’ve narrowed it down to a selection of machines I believe are suitable (again, correct me if I’m wrong) and I would really value opinion of the experts on here about which would offer the best suitability, which company offers the best customer service and see if there are any other machines that people can recommend to add to this list: Cobra Class 18 http://www.leatherma...alog.php?item=5 $1,595 ($1,445 with Dave’s discount) Spoke to Dave Spiegel, who I must say is a class act, about his machines and he believes the Class 18 would be the tool for our work. He also offered $150 of the cost of the machine in recognition of the extra $1000 or so I will be paying to get it to the UK. $695 shipping (understandable from the West coast). Artisan Toro 3000 or 618-1 LTHR http://www.a1sewingm...antoro3000.html $1,950 http://www.a1sewingm...n618-1lthr.html $1,675 Spoke to Ron Anderson at A1SewingMachines and he suggested that the Toro3000 might be overkill for my needs but that the 618-1LTHR would be more suited. He questioned the Toro’s ability to work on medium leather as well as the 618-1LTHR would. Any help on that one? Yet to get shipping price back but estimated at $400-$600. TechSew 2700 or Techsew 5100 http://shop.raphaels...products_id=289 $1,599 http://shop.raphaels...products_id=562 $2,695 (pretty much out of the price range unless I get a seriously compelling reason to opt for this one.) Spoke to someone called Michael, I think, who said the 2700 wouldn't be suitable as my work was on the heavier side of medium and recommended the 5100. TechSew did however over shipping at $350. HELP! And thanks in advance.

- 5 replies

-

- leather sewing machine

- cobra class 18

- (and 3 more)