Search the Community

Showing results for tags 'textima'.

-

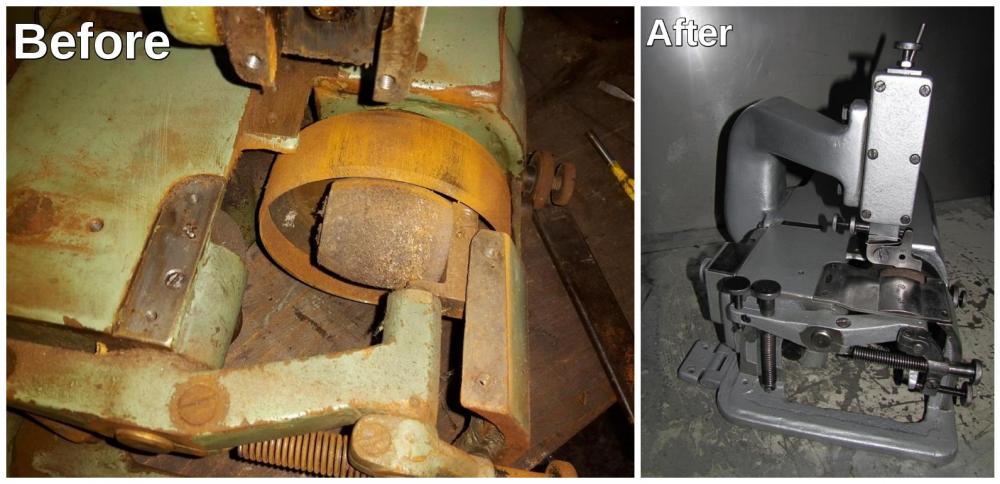

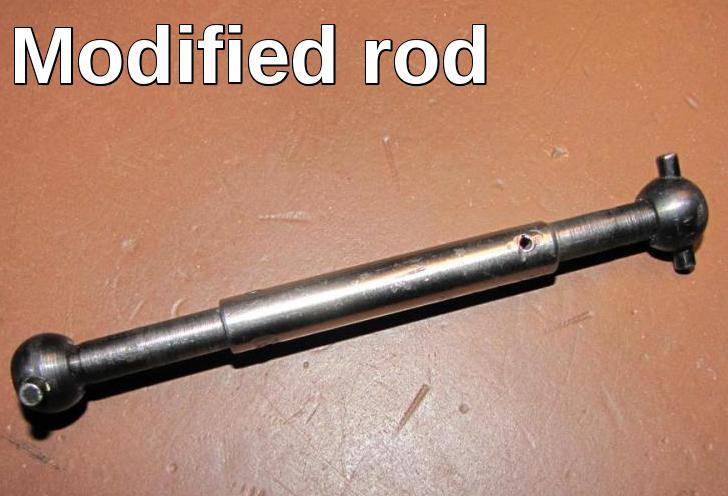

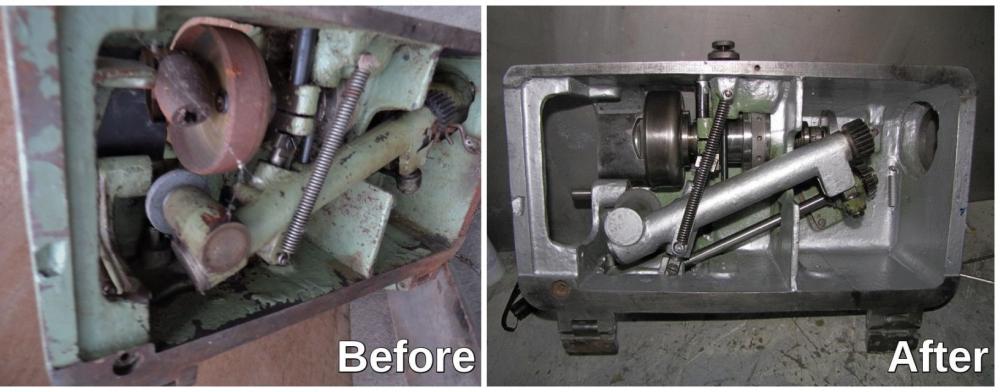

Couldn't resist buying this 'boat anchor' for the price of a piece of leather. Made probably in the 50's in former East Germany - Textima was an old brand of machinery, related to CLAES brand, part of VEB Textima Co. LW users helping with this project directly or indirectly: - @Constabulary - who did most of the work: all the mechanical restoration. @RockyAussie and @Trox - very helpful tips along the way. Also @CampbellRandall (Dan) - very helpful videos regarding skiving. Thanks a lot!! The machine was badly rusted as you can see in the pictures (in the left is an original photo from the ad, before restoration). Couldn't find any documentation, didn't know if it's complete, if we can find parts for it, or if this thing will work again. But definitely looked very robust and seemed it was worth restoring. It is a bit different from other modern skivers: all the active parts (bell knife, feed wheel, sharpening wheel) are moving together with a ratio established by the gears (feed wheel moves slower). They all start/stop moving when the clutch is engaged/disengaged by the pedal. Machine is ALL gear driven (no belts inside) and the original clutch was on the outside. Found out: the old, heavy, wide-belt external clutch needed to be replaced with an external clutch motor. Only one part was missing: the feed wheel drive-rod (and a cover). We ordered the missing rod but realized it was too short, so Constabulary adjusted this by cutting, gluing and pinning on a tube (photo). Machine needed to be stripped to the last screw, every single bit was taking care of. That included: electrolysis bath to break some parts loose, de-rusting, hammering some parts out, heating them with a torch etc. Many components were all gummed up. Original paint was very thick, pretty difficult to remove. Following was the painting and partial assembly, greasing, shipping.

- 13 replies

-

- skiving machine

- skiver

-

(and 2 more)

Tagged with:

-

This machine has a metal plate fastened to the front with the name Pilgrim Shoe and Machine Co and the model number 200-3. Pilgrim told us recently it is a Claes 8345-30 large bobbin machine manufactured by Textima. They also told us it was marketed in the United States with the Textima, Claes or Tuffy label. There must be something to that because I notice several of the larger equipment suppliers like Landis and Shoe Systems Plus show the same parts numbers for Textima, Claes and Tuffy. In any case, the machine was purchased by my company in used but excellent condition 30 years ago. It was used perhaps one day a month for 20 years to patch leather safety garments and attach aluminized Kevlar sleeves to molten metal protective mittens and Gloves, it sewed with Kevlar thread beautifully. Thirteen years ago the business and machine were sold. I doubt the machine was even used after that, because the woman who had operated it had retired and no one else had any knowledge of how to operate it. There was no operators manual or literature. Three years ago the buyer moved out of the building we had leased to them and left the machine behind saying it was broken and that part was no longer available, apparently someone inexperienced had tried to operate it. We sold the building and the machine three years after that.. I wanted the machine at that time; I had always admired it, but didn't act on it. It's a beautiful, well made and attractive machine.......like a piece of art, something old-timers like me (and others no doubt) appreciate. I still ride a 1990 Harley-Davidson with 240,000 miles on it that I bought new. Well, a few months ago the attraction became too great, and I purchased the machine back. Unfortunately the lady who had operated the machine all of those years, along with her husband, died in a motorcycle accident, may they rest in peace. So here's the situation: first, my only experience sewing was in high school cuffing trousers, second, I don't know a thing about industrial sewing machines and third, I intend to refurbish this machine. To that end I've spent hours doing research on this fine website. I've taken scores of pictures, I've pulled it completely apart, taking pictures along the way and I've cleaned it totally. The teeth on the rack and the shuttle driver look perfect, the end play in the main long shaft between the pulley wheel and the feed cam is .004", and after I figured out how to thread and adjust the machine, it seemed to sew well............that remains to be seen though. I don't see anything broken except for a small spring in the large cylinder that holds the needle bar and feed mechanism. That piece is on order. By the way, in doing research, I had occasion to send a few emails to Europe, but needed to do them in German. I stumbled on to Google Translate. For those of you who haven't used it, it's miraculous, I've bookmarked it. You type a message in to it in any language you choose (English in my case) and it gives you a translation in any language you choose. Also, if you can copy and paste text into it and tell it what language you're putting in and what language you want out (again English in my case), you'll get it. Hope it helps someone looking for parts or trying to translate an old operator or repair manual. What I would like to ask good people is: 1) what suggestions do you have to do the restoration properly? 2) should the machine be re-painted or left as is? 3) would anyone have any literature of any type for this machine? Thank you, thank you very much.