My history with leather sewing machines

PRELUDE

Most members of this forum know me as a frequent poster on the Leather Sewing Machines Forum on Leatherworker.net. Some may assume that I know more about specific machines than I actually do. However, in many cases, I have had or currently have plenty of hands on experience with a particular machine, or type of machine. As a result of my own experiences with various types of sewing machines I am often able to give advice or provide assistance to other members who ask for help with this or that machine, or want to know about its capabilities or limitations.

I have owned or worked on industrial sewing machines ever since 1985. But, my hands on experience goes much further back than that. It all began when as a boy I hung out at my Father's tailor shop. I watched him sew clothes both by hand and with his Singer sewing machine. While I don't know for sure, I believe that he used either a Singer 31-15 or a Singer 96k40. I only remember that it had a clutch motor and looked much like the Singer 31-15 that is sitting in my leather shop.

I never touched that machine until I was in my early teens. One day my Dad sat me down in front of the machine and explained what the floor pedal and knee lever did, as well as how to feather the clutch, control the material, hold back the starting threads and wind a bobbin. He also taught me how to not sew my fingers or thumbs! This was in the early 1960s and it was my first experience with any sewing machine. Of course, I had other plans and wanted no part of that occupation. I never sewed on that machine after about 1964.

Fast forward 20 years to 1984 when I got into leathercrafting as a hobby. Like most newbies to the craft, I began by lacing and hand sewing my projects. It didn't take too long before that got old. The final straw was when I decided to construct a leather vest from a pattern pack I bought from a Tandy Leather store. I knew from the first attempt at penetrating the chrome tanned leather than I was going to need to do this on a machine. This was the moment when I began my unexpected adventure that became a quest, not for a mystical Ring, but for a sewing machine capable of sewing real leather.

THE JOURNEY BEGINS

I still remember asking the manager of the local Tandy Leather store for his recommendation for a sewing machine that could sew the vest I was making from Tandy's pattern pack and leather. His first thought was to try out a machine that another customer was willing to sell and would bring to the store. That machine was there the next day. It was a Singer 503A Slant O Matic Rocketeer which had a slant needle system. I brought in a small piece of the leather I bought for the vest and placed two edges together under the presser foot, lowered the foot, held back the threads and pushed slowly on the controller pedal. The needle came down at its designated forward slant angle, met the top grain of the leather and broke into zillions of pieces that Rocketeered into the store. I passed on that machine.

YOU REALLY NEED AN INDUSTRIAL SEWING MACHINE

Those were the Tandy manager's exact words after the disaster with the Rocketeer. I asked if he knew where I could find those. He had no idea, so I let my fingers do the walking in the phone book. Sure enough, there were industrial sewing machine dealers all over the place within my city limits. I picked the closest dealer and called them, asking if they had a machine that could sew leather vests. The owner assured me that he had exactly the machine I needed. I headed there as soon as I hung up the phone, bringing a wad of cash with me. And what did I find waiting for me when I got there? A Singer 96k40, mounted on a 20" x 48" wooded top, steel legged table, with a big clutch motor underneath. It looked like the sewing machine my Dad used in his tailor shop for many decades. I bought it for $300 cash, which included a few packs of #16 and #18 needles, spare bobbins, a couple cones of heavy cotton or polyester thread (button weight) and a small bottle of sewing machine oil.

NOT EVERY INDUSTRIAL SEWING MACHINE IS A LEATHER SEWING MACHINE

It didn't take very long for me to discover that as impressive as that old Singer black body machine was, it was not a leather sewing machine! It did okay when sewing two flat seams, but skipped stitches and broke needles when I tried to sew hand cut fringe onto the back, or pockets onto the front sides. The third layer was too much for the straight stitch, bottom feed machine, especially when it encountered a new layer on top. It tended to just come to a halt and sew into the same hole until I remembered to use the knee lever to raise the foot to get on top of the new layer. This was really just a tailoring machine.

Disappointed, I called the dealer I bought the machine from and explained the problems I was having with the machine. He said: "then you need a walking foot machine." He told me to keep 96k40 and the table and for another $250, sold me what he called a walking foot machine head. It was a Singer 31k47 and it dropped right into the same cutout in the table. The motor needed to be readjusted to compensate for the higher balance wheel/pulley and the knee lever had to be moved to hit the lift rod on the bottom of the machine. This machine was not a walking foot foot in the true sense. It had a spring loaded follow foot that moved back with the top layer, which was transported by the bottom feed dogs, then lifted and sprang forward for the next stitch. It had an alternating inside foot, which, like the needle, remained in a static position and just moved up and down. It did however manage to climb over new layers and sew my leather vest!

After finishing my leather vest I began experimenting with sewing belts and straps. I found that the spring loaded presser foot on the 31k47 tended to slip on the top of my carved and hand polished belts. The hard veg-tan leather didn't feed well on that machine and it didn't like any thread larger than about #69, although I did coax it into sewing with #138 thread. So, I made some inquiries at other industrial sewing machine dealerships and finally found one that clued me into the fact that what I needed was a triple feed walking foot machine. They had them and wanted anywhere from $1500 to $2500, depending on the age and brand. This was a problem for me at that time because I couldn't come up with that much money in one shot.

Just when I thought I had reached a major roadblock, a friend told me about a friend of his who wanted to sell all his leather craft stuff, including a sewing machine. After meeting with that guy, I handed him $1000 in cash and went home with a ton of hardware, leather, patterns, kits and ... a Singer 111w155 triple (compound) feed walking foot machine! That machine paid for itself and all the hardware in two months.

WHAT KIND OF SEWING MACHINE DO I NEED TO SEW HANDGUN HOLSTERS AND KNIFE SHEATHES?

I think a lot of leathercrafters reach a point of development when they want to make holster and knife sheathes and need a sewing machine that is truly up to the task. I reached that point in 1988. I had tried to sew pancake holsters and three layer sheathes on my Singer 111w155 and found that it struggled to penetrate the hard leather. Further, it could not handle any thread thicker than #138 bonded nylon. I tried using a #25 needle and #347 thread and all it did was skip stitches, break thread and filigree the leather. And, it was all I could do to start it sewing at all into that hardened leather. So, back to the industrial sewing machine dealer!

I HAVE JUST THE MACHINE FOR YOU TO SEW VERY HEAVY LEATHER...

That's what he told me on the phone, sometime around 1887. When I arrived at the store I was taken to a back room and shown a monster machine made by Singer; a model 132k6. I was told this machine will sew anything you can fit under the foot with up to #346 thread. That foot, which lifted to 1/2 inch, was a spring loaded foot, just like my 31k47, with an alternating up/down inside foot and static position needle. I had my doubts, but parted with $1300, plus tax, and took the machine home in my 1976 Ford Country Squire station wagon.

I didn't beat around the bush with the 132k6. I loaded the top and huge bobbin with #346 thread, verified that it had a #25 leather point needle installed, cranked down the foot pressure, tightened the top tension and began sewing into a mock-up holster with an 8 ounce side filler. The leather lifted with every other stitch until I cranked the pressure spring all the way down. I did get it to sew up to about 3/8 inch of veg-tan holsters and knife sheathes, but had to almost sew one stitch at a time with the handwheel. Like the smaller 31k47, the presser foot tended to slip on top and this resulted in varying stitch lengths. This was not what I had in mind for a real leather sewing machine. When I complained to the dealer he shrugged and said it was the strongest machine he had or knew about. He would not buy it back ;-(

I limited my few holsters and sheathes to two layers and sewed them on the 132k6, biding my time. I did fine into a little over 1/4 inch of veg-tan with #346 thread.

During that time frame I began buying old Singer sewing machines from that dealer and from individuals. I had post bed machines, long arm and very short arm cylinder arm walking foot machines, a 45k25, a pull down lever sole stitcher, a blind stitcher and a small table top serger (I did some garment work to make money). I acquired two skivers: a Fortuna for light leathers and a United Shoe Machinery Puma for veg-tan and shoe soles.

AT LAST, A REAL HOLSTER SEWING MACHINE!

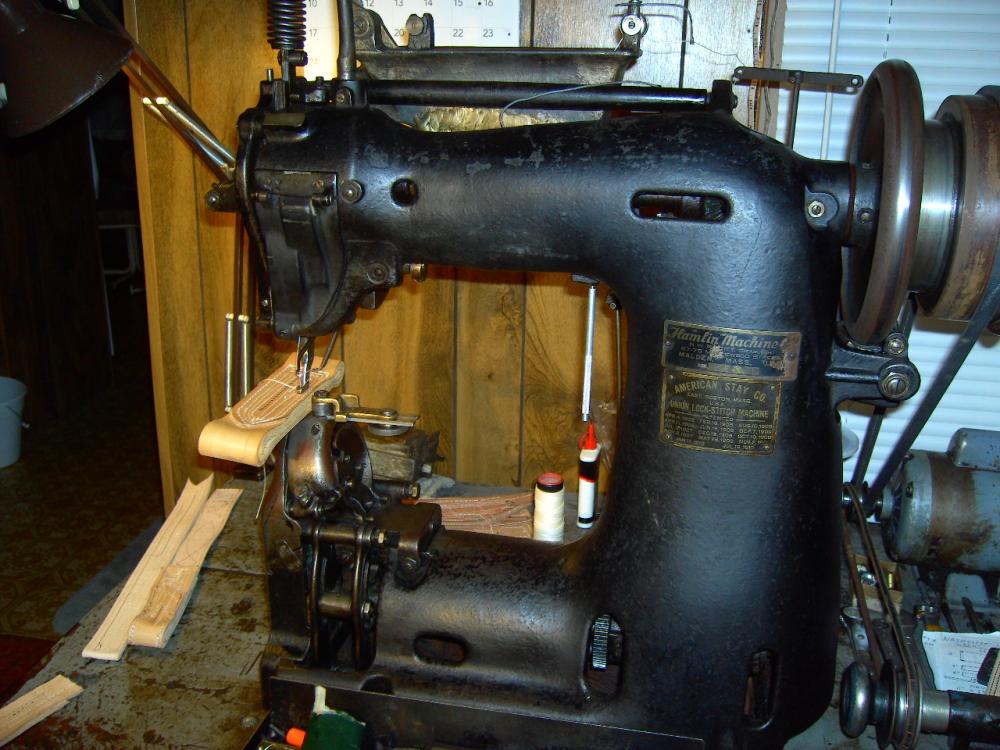

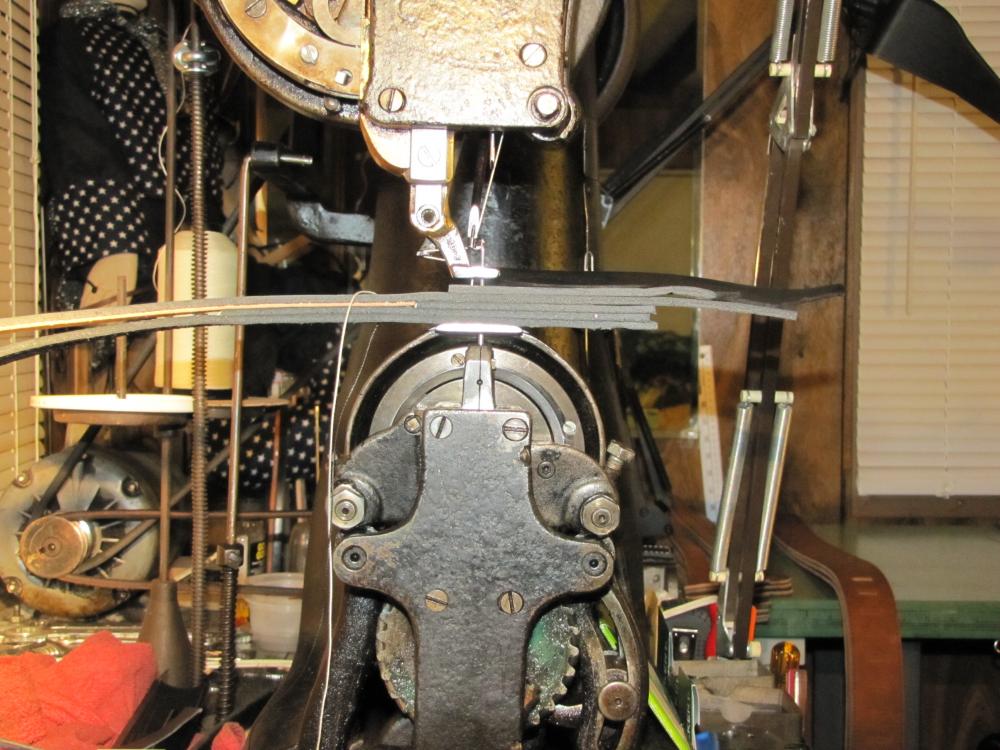

It was 1988 when I finally found a sewing machine that could actually do serious sewing into thick stack of leather, with heavy thread, producing stitches that didn't vary every few inches. I stumbled upon it at a Tandy Leather distribution warehouse, which was behind a retail shop. After rounding up some hand tools and other supplies, I asked if I could see the warehouse. The manager and I were the only people there and he said "okay." He switched on the lights and let me into the warehouse. As I looked around in amazement at all the products and kits stacked everywhere, something very large and black caught my eye. Right in the middle of the huge warehouse was the biggest sewing machine I had ever seen, much less imagined. It stood almost as tall as my head! It was a Union Lockstitch Machine, made by Randall, in NY, NY. I jokingly asked what they used it for and he told me that they had a man who used to sew bags, horse tack and large kit parts on it, but he had retired. The machine hadn't been turned on in at least 5 years. Best of all, they planned to put an ad in all the newspapers in the area to try to sell it! So, we haggled...

An hour later I had left a $100 deposit on the machine. The next day, after going to the bank, I went back, 60 miles away from home, and bought that Union Lockstitch for a total of $1500. The manager and one employee helped remove the head from the table and loaded the beast into the back of the Country Squire wagon (it had a 400 c.i. motor). All it came with, besides the head, motor and table, was the needle and awl that were installed, one bobbin that was in the shuttle, and one spool of white #346 bonded nylon thread.

I spent another $2000 over the next year buying needles, awls, bobbins, accessory feet, throat plates, edge guides and replacement parts. Most importantly, I bought two threading rods. The owner of a harness shop was nice enough to run a copy of his own manual for his Union Lockstitch.

Having that machine was like having the Stargate to me. It sewed holsters and sheathes up to 3/4 inch thick and above. I figured out how to trick the foot to lift higher and used it to sew a holsters up to 7/8 of an inch! This was around 1989 and was very unheard of at that time. I got some of the heaviest thread made and by changing to the largest needle and awl was able to sew holsters with #554 thread, or 6 and 7 cord Barbour's Irish linen thread, run through Sellari's liquid wax in the huge waxpot.

AN END COMES

Leather work was a good business for me until 1996. By that time things were changing. The house I had been renting, where I had about 13 industrial sewing machines setup in the basement, was sold to a new owner, who asked me to leave. Despite searching for a half year, I couldn't find any house that was comparable at anywhere near the price I had been paying. In all the years I was renting the house for tiny increases ever few years, rents had gone up in that city to almost triple what I was paying and could afford. I contacted a good friend in another city, 250 miles away and he found a house in his city for half what I had been paying. But it was a much smaller house and the basement tended to leak when it rained heavily. So, I sold all but two sewing machines. I only kept my Union Lockstitch and the first machine I bought, the Singer 96k40 (which now had dozens of feet, folders and accessories, including a roller foot conversion). I did keep all of my thread, hardware, tools, books, patterns, dyes, arbor press and cutting dies.

When I made that big move I tried doing leather work in the new location, but didn't have much success. I had been developing skills using, building and troubleshooting computers and came to a decision to switch careers. By 1998 I was a computer troubleshooter and no longer did any leather work. In the year 2001, I sold my Union Lockstitch machine and all of the parts and cartons of thread that went with it (thousands of dollars value), for $5,000. A few years later I sold almost all of my leathercraft tools, patterns, dyes, cutting dies, hardware, books, the 96k40, press and anything else I had pertaining to that trade and life. I did keep a small set of special stamping tools, some setting tools, a few alphabets and a head knife. All these tools were inside a Graflex press camera carrying case.

This Union Lockstitch is a REAL leather sewing machine!

NEW BEGINNINGS (next entry to come soon)

After doing computer work for a dozen years, in 2010 I came to the conclusion that my heyday as a computer builder and troubleshooter had reached a natural conclusion. It wasn't exactly an overnight event, but rather a slow decline in business. The final straw was when I was called into a computer store, with whom I had previously left my resume, for an interview for a computer technician. The owner took one look at my 62 year old face, looked down at his hands, then asked questions like: "How well do you get along with younger workers?" "Do you have any medical issues that would interfere with doing your job?" "Do you have to go to a clinic or hospital for regular treatments?" Not once did he ask about my abilities as a computer builder, troubleshooter, or network tech!

Luckily for me I had a very good long time friend who owned a leather work store. I asked him if he could use me a day or two a week to help in the shop. He tossed me a few days here and there and eventually took me on as his right hand man. I did most of the sewing and repaired leather jackets, sewed patches onto vests, repaired purses, built holsters and replaced zippers. When I first went to work for him in 2010, he only had an Adler 30-70 motorized long arm, high lift patcher. But, he later acquired a Cobra Class 4. I was a natural on both machines.

In 2009 I wanted to do some leather projects on my own, so I hunted on Craigslist and found a really nice Singer 29k172, long arm, big bobbin patcher, complete with a matching cast iron treadle base. I began taking in some repairs and custom builds at home, which paid for the machine in a few months.

In the middle of 2010 I bought a used National 300N walking foot machine from an upholstery shop. Then I began taking rifle slings and guitar straps home from my friend's leather shop to sew on a piece meal basis. I sewed so many slings and straps that it paid for my National sewing machine in one month!

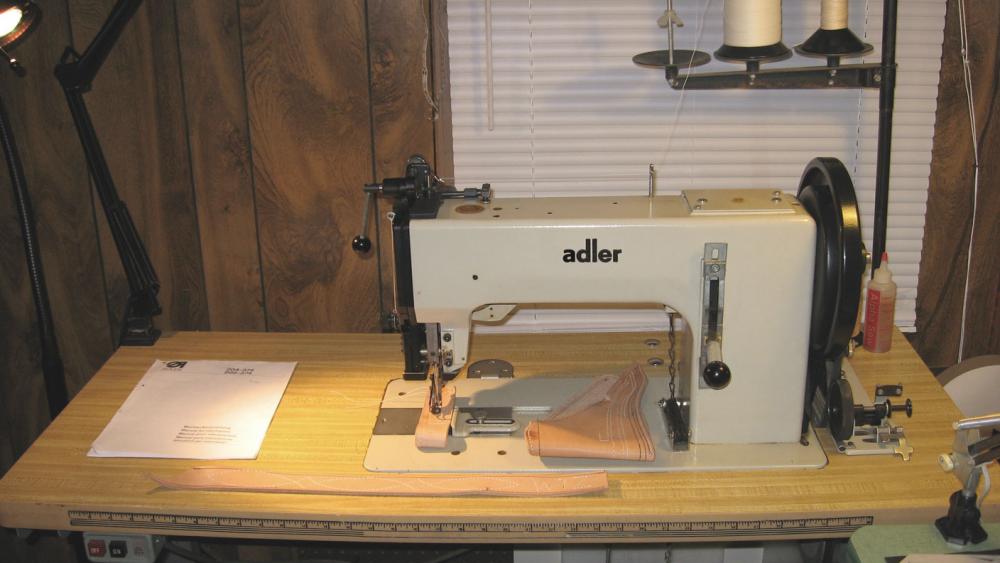

One year later, in 2011, I traded a recently acquired (Craigslist again) Adler 204-374 flat bed machine for an old, barebones Union Lockstitch machine. It was on again!

Stay tuned folks! There's more to come.

More photos of sewing machines I have had or still own.

3 Comments

Recommended Comments

Join the conversation

You are posting as a guest. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.