-

Posts

122 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Skald

-

Yeah no problem really, most people here are Americans so it's not easy to see I'm from not around. I've never used PMC, but I might sooner or later. I am in a phase of putting together a small business, so I have to think cautiously about where I put my money right now, and make the right priorities. Let me know about the website when it's up again, sounds interesting for sure. I've done some money clips, and you are right that you'll have to first heat it before bending it (preferably in a jig), and then strike it with a raw hide mallet or plastic mallet, you can also put it in a hmmm... tumbler(?) meant for polishing rocks, along with these small stainless steel balls etc. - and it will harden it up too. But then, after a year or so of use, the "strength" might very well die out, and you'll need to tamper it over again. Because of that, I wouldn't try using snaps etc. out of silver only. Opening and closing a wallet several times a day, would kill the "vigor" of the silver in quite a short time I guess. I am using a silver money clip I made right now, as a prototype, to see if I dare try selling them.

-

The "silver(color)" issue is always present if you order stuff from eBay, in best case you'll get pure silver, sometimes silver plated, and sometimes no silver at all, but "silver color" - and they are not always so nice as to be clear what they mean by silver. Here in Sweden, stamping silver ain't necessary any longer (by law). But most people who deals with it does it anyway, as people still want stamps as some sort of proof of what they just bought. Making snaps etc. directly out of silver is probably not a good idea, since it's not very good for that particular usage. Anyone who have made for example a money clip will know why. So it's more a practical thing, and less greed if you make the decoration part of silver, and the rest of stainless steel for example.

-

I'm a bit "uptight", and don't want to use other peoples stuff more than absolutely necessary, so I'll try to stay clear from these parts as well hehehe... I can go as far as to use real HARDWARE such as snaps etc., but as much as possible should be my own design and creation.

-

I'll try to locate such a machine, sounds like an "investment" for future use. Until then, I guess I'll stick to folding/sewing edges instead. I don't want to be an amateur told apart from the experts.

-

My experience is that kids are swift learners, and I bet he would learn to use any kind of belt buckle in no time, just if someone showed him. A four year old will soon be able to control the TV, Xbox, computer and what not - so a belt buckle should be a piece of cake really.

-

Probably one of the most worthwhile suggestion I've seen so far. Looks like a good solution.

-

Might be useful, if I grind off the nickel plating before soldering. Soldering on any "plating" will cause problems sooner or later. I'll go to my father's workshop tomorrow and try soldering a piece of silver to a rivet, just to make sure it works. Thanks for the tip.

-

Yeah, I have seen that there are stuff commercially available, but I have ideas for own designs, and that's what's causing me the bugs in my brain. I'll try soldering some scrap silver to a snap button, I think that might be the easiest thing to solve. But when it comes to that loophole thing for example here http://www.onetooman.../hannoid_fr.jpg I really can't think of any solution. I can do wax carvings and castings etc., but I am quite sure I can't manage to make a silver eyelet, that's a little too much precision work hehehe... Well, I'll do some field investigations during the summer, and see what I can come up with. Edit: Been thinking of this with soldering some silver design directly to a rivet, and can't see much of a problem in doing that in itself (depending on what sort of rivet it is, if it's chromed, it will eventually fall off along with the chrome). But how on earth would I be able to fix that rivet? It would probably ruin the silver design thing quite instantly (by either hammering or using an arbor press). I could perhaps put some layers of soft skin under it, but then the snap would probably not set properly, due to the problem of keeping it straight etc. So, I guess it would be best if I made the silver thing with sort of "prongs" on the backside, and a matching washer with holes underneath. And then (my English is really not good enough for this!) put the prongs through holes in the leather, and put the washer at the back of the leather, slide the prongs through the holes of the washer, and then sort of "hammer them down" the old time rivet way. I thought of soldering the thing on the backside, but then realized the leather would burn pretty badly. And then of course, just set a regular snap rivet on another piece of leather, and sew both parts together - hiding both the washer thing, and the back of the snap rivet. That's probably the best solution I can come to think of, most other ways are ruled out either by the element of heat, or the pressure to set snap rivets. I must make some prototype thing out of scrap material, and see how it holds up.

-

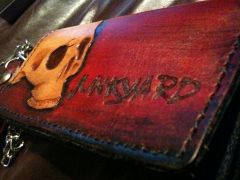

Looking at sites like these: http://www.biker-wallets.com/ and http://www.onetoomanydesign.com/leather/index.html you see quite some "custom made silver details", and I don't know really how they make them. I do have some experience both from wax carving, casting and soldering etc. when it comes to silver, but maybe that makes me even more confused. I mean, how do you make "snap buttons", rivets etc. with those silver adornments? I haven't seen things like these IRL, just pictures, so it's a but difficult to grasp. And I don't have like $500 to purchase a wallet, just for looking at. So, if anyone have a clue, or even experience from anything similar, please fill me in!

-

-

Cool! Thank you, I'll give it a try.

-

Thank you guys, you are truly the best. And Phatdaddy, thanks a whole bunch! Yeah, you are right. There are no exact "standard sizes". But I got like 15 or so different folders (most of them, I don't know where! I occasionally find one in a pocket or bag when I least expect it hahaha...). But most of them I got are differing like ½ an inch or a little more or less, and for the thickness, it doesn't differ all too much either. Of course there are these baby size knives too, but no one would probably try to use a larger pouch for them anyway. I guess I'll can try keep searching for other folder pouches out there, and see aprox how large they are. Only problem is, they hardly ever tell us what "thickness" or knives they are good for, i.e. how "high" their pouches are. I just found an old BlackHawk cordura pouch, which fits most of my folders, so at least I have something to measure.

-

Thanks for your words of wisdom. If you look at these for example (that I found yesterday, shortly after creating this thread) http://www.knifekits.com/vcom/index.php?cPath=41_264_323 you get like two of the measurements, but how "high" is it? I don't know really how to put it, they are like 5 x 1.5 in height and width, but how hmmmm... "high" is the space inside really? I don't feel really okay with buying some of these and some from Tandy just to find out. But I guess I might have to do it in the end.

-

Dyeing Leather White.

Skald replied to Gawdzilla's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Much badmouthing on Fiebing's white color here. I'll tell you my experience. I took a piece of natural tan leather, and a piece of pitch black dyed with vinagroon (or vinegaroon, or however you decide to write it hahaha...). And first put several layers of white acrylic Cova Color on both of them, undiluted. Then I added some several layers of maybe 40/60 acrylic & water to both of them, I guess maybe 5-6 layers. I also tried Fiebing's white color, and it indeed took maybe 10-20 layers, before it actually became really white. I didn't seal or otherwise treat any of these in any way, before testing. As for the test, I first scraped all the different applications with my thumb, then my thumbnail, and a little (but not much) of the pure acrylic came off when using the nail, especially on the "groon'ed" piece of leather. None came off on the Fiebing's color areas. Then I tried to rub the colored areas towards the corner of my table (not very hard or much), all the layers of acrylics came right off, completely. The water diluted parts still had some pale white shadow left to it, but it looked horrible and was really ruined. The Fiebing's white color lost about as much color as the water diluted acrylics left behind when rubbing against the table, some came off and left the black leather shining through somewhat. So I am all Fiebing's white, every day of the week - at least if I am doing anything that's supposed to last, and something that's meant to be used, even if it takes many layers before it gets really white. And no, I don't work for Fiebing! -

I wonder if anyone knows about the most common measurements of folding knives? I have some several myself, and most of them are quite the same size (Buck, Böker, Magnum, Gerber and so forth), of course some are quite a bit more bulky, and some are of course notably smaller. But, are there some length/width etc. values that are most common? What makes me ask is because I want to make some leather sheaths for folders, but I don't know really what size they should be (maybe three different, that wouldn't hurt). I am quite sure I have seen some leather sheaths for folders around, meant for "just about any knife", and I am also quite sure that I have seen some "kits" for folder sheaths - but of course I can find none of these when I want to have a look at them. So, does anyone know? Maybe you have got some orders for folder sheaths for knives you are not fully aware of the size of? How did it turn out?

-

Depending on the "popularity" of the phone, there could be a "dummy" available for a few dollars on eBay. Might be well worth it, especially if you are going to make more of them later. The cost for the dummy could of course be included in the price.

-

Vinagaroon Stinks!

Skald replied to rccolt45's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

It's a temporary problem, and I guess you'll have to live with it for a week or two. If you are selling the goods, perhaps let it "stink out" before passing it on to buyers. In any case, it will eventually wear off. All smells do. -

I'll get myself some parchment, or "vellum". Probably from calf or goat skin. I intend to try make a lamp out of it, i.e. sew it to a wooden frame. I want to paint it for decoration, but I have no idea what kind of dye/ink I should be using. And I guess I need to put some finish on it for "sealing" it, as parchment gets stained pretty easy, even from touching it with your bare fingers, and just some few unintentional stains of any fluid (like water) might ruin it. So, does anyone have any experience from this kind of leather material? What on earth should I be using? I've tried to "google" it, but come up with almost solely pages dealing with fake "parchment" made of paper, meant to be looking like the real deal.

-

Hahaha, I must try it sometime, at least on a scrap bit and see how it works - might be "the new black". I'll try this Dura Edge anyway, next time I order stuff. It might very well be that I take time to make a proper folded edge anyway, instead of this weird one. But it have indeed caught my attention, that it have lasted this good over all this years. I had a iPod-case with a similar weird compound on the edges, and it was devastated and almost completely worn away after a little more than a year. Not very impressing.

-

Borrowing this thread. Different methods and tutorials for getting nice edges are not always possible to use for all projects. I am looking for some gum/rubber-like compound to seal edges, where no burnishing etc. is possible. It's for a wallet, made out of rather thin material - all-in-all, the edge is probably not even 2 mm before the "mysterious ciompound" have been applied. I am trying to make a wallet similar to a Timberland wallet I have, and this strange compound on the edges have lasted for more than 4 years now, and other parts of the wallet are starting to "give in" before these gum/rubber/silicone covered edges.

-

Thanks for the input. Fiebing's product is called "Dura Edge" it seems? Duracoat is that thing you cover guns and knives etc. with, if I am not all wrong? Does anybody know if it works on these finer edges? On this wallet I mentioned, it's a matter or like 2 mm's of edge in total, including the suede (or nubuck?) and the nylon interior lining etc. So it must be much like silicone or something like that.

-

I have a Timberland wallet, which I have been using for the last 4 years or so. It's made out of really thin suede, and has this "rubberlike" edge coating, which seems really durable and strong. There isn't a single crack or other signs of "tear and wear" on the edges, even though the wallet itself starts to look very vintage (but fine). My question is, does anyone know what might have been used for this? I can't seem to find any products that sound like the same thing - and I really would like to use that for some future projects, and not end up with something of lesser quality than this. Unfortunately, I can't get any photos of it to my computer, so I can't show any pics of it.

-

Sorry if I'm just not paying attention, but would do you do with corners? Sometimes it's maybe not possible to hide the ends of the pieces.

-

I have often fond that the leather I am tooling is at its best the day after, if I put the piece to rest in a ziplock bag over night, and then just sweep it a couple of times with a wet sponge the next day. Then I get this "burnish" kind of marks from tooling. So, naturally, I have started to case the leather at least a good couple of hours prior to start tooling it. Good tutorial btw.