-

Content Count

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Blogs

Gallery

Store

Everything posted by LBsaddles

-

The Cowboy machine is no longer for sale but the singer is still available.

-

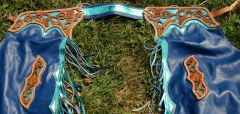

Heres one more picture

-

The customer really likes it If you can see the horn in this picture i filled under it so the leather looks like a horn cap concho but its all leather

-

Just finished this Wade for a customer. i was sure how it would look since its not tooled much but it turned out nicer than i expected.

-

I am looking to relocate to Athens Texas in late July / early August. I currently have a small shop in Ohio where I build tack, saddles, and rodeo chaps. I have experiance but I know I can always learn more. I have sewing machines and hand tools. I have a good background in stamping and carving, if you would like to see some of my work my website is www.leaningbarnsaddles.com If anyone in that area is interested in possibly employing me please PM or email me jeremiah@leaningbarnsaddles.com I can also supply references from other makers I have worked for and i am willing to produce a product of your choice as proof of my skills. Thank You Jeremiah Tucker

-

Well no you can't order from those (not nice words) people at Weaver. Where are you located? I can get them, I order stuff from them through another guy that I know that has a Weaver account. The worst part about good old Weaver is your first order has to be $500, so you can se they are really accomidating to the little guy. Possibly if you another maker or shop that sells weaver tack they could get them for you.

-

Depends what you are doing, but when I am braiding I will soak it in warm, not hot, water for an hour or so then I put it in a bag like I case leather in and leave it there for an hour or so and its ready to braid. That said i'm using flat rawhide or strings I have cut, not a dog bone.

-

This is a great topic Being a very young saddle maker, I'm 25 and I've only been building an my own for a year now, any time I had the chance to learn I took full advantage of it. Also the people that gave me these oppourtunities could see that I thoroughly enjoy all aspects of the craft. I think there is a problem with my generation. Everything is so easily achieved, they have had everything given to them and can't put out an honest effort. They don't have a passion for work, they just want the money and as much as they can get , even if they have no experience. When I was "apprenticing" I work for room and board and was alowed to build some gear for myself, I loved every second of it. I spent the first month building stirrup leathers for bronc saddles, bronc halters and lacing stirrups. Most people my age would have become frustated that they were not learning anything, but I learned everyday and every spare second I had I would watch them build saddles. I worked there when they needed help on and off for 2 years and never built a saddle but I had been allowed to sew certain parts and stamp and carve parts of them. A few months later I was breaking colts with another man that built a few saddles a year ( He broke between 70 and 100 colts a year). He had a tree that had been started then torn back apart because a customer changed his mind. As a trade for work I took that tree and some leather and started building a saddle. When I completed it I took it back to the first man I had worked for and he critqued it but said that he wished that he would have been able to build his first one that nice. I told him "Well I learned everything from you." He said " well you must pay attention well because you never made one here." I guess what I'm saying is that ability does not out weigh desire. I was blessed to have decent ability that could be improved and a huge amount of desire, but thats what is lacking in the world today. If I could only disassociate myself from "my generation". YOU HAVE TO BE WILLING TO WORK FOR WHAT YOU WANT!

-

-

From the album: Leaning Barn Saddles

© © leatherworker.net

-

From the album: Leaning Barn Saddles

© © leatherworker.net

-

You might try Chicago Stockyards Saddle Tree they have a half saddle tree that is a slick fork by the way it looks in the pic. Here's the link http://www.literidetree.com/larkbunting.html but i'd call them because i have emailed them twice with no response

-

You're welcome, when you finish your bag post it so we can see how it turned out.

-

Its the same buckle that is on the top of horse collars for a harness. Here's the link to Weaver its on the 8th page http://www.leathersupply.com/downloads/catalog/Hardware/LoopsSlidesDees&Fasteners.pdf . they have them in black, stainless, and brass.

-

I've been messing around trying to find something for reins that would put a waxy finish on but could be re-applied as it wears. What I came up with was to get bees wax and olive oil and put it in a crock pot and set it on low for a day or so stirring every once and awhile until it is good and mixed. Then as it cools stir it about every 5 to 10 min. so it doesn't seperate. I don't have any exact measurements on each yet but the first batch looks like bag balm, it works well and can be applied over and over but I want a little more wax in it next time. It doesn't change the color much if at all and is completely waterproof without any glossy finish.

-

-

Thank you both very much for the suggestions and i think i am going to order the DVD. On the Dvd does he explian about how th make the flow of the pattern look correct

-

Im having a hard time getting oak leaf patterns to look right. I have looked at a lot of patterns some look like sheridan and some just look random. The biggest thing about them to me is none of it looks like what oak leaves on the tree really look like. I saw a picture of somthing Chan Geer made that look more like what I wantbut it has floral in it too and the pic is small so i can't really get a good idea of how to do it. If anybody has a way to make this easier please let me know i will appreciate it greatly.

-

I also have a singer double needle model 138 w 102 for sale $800.00 it has a table, tread stand and a 3phase clutch motor. It uses pre wound bobbins i'll throw all those i have in and 20 needles

-

I have a Cowboy Model 4 heavy duty Flat Bed machine I would like to sell $1400 obo. It has a stand, a speed reducer and extra needles. It needs a new servo motor they are about $150, the control board went bad in the one on it. If you're interested my numer is (419)560-9398 Jeremiah Tucker

-

I have a Cowboy Model 4 heavy duty Flat Bed machine I would like to sell $1400 obo. It has a stand, a speed reducer and extra needles. It needs a new servo motor they are about $150, the control board went bad in the one on it. If you're interested my numer is (419)560-9398 Jeremiah Tucker

-

I'm not the best with wood, iI'll just stick to leather. I find is a little more cooperative. Chaps and tack are more my forte, but it was a try.