BOHUNTER

-

Content Count

23 -

Joined

-

Last visited

Posts posted by BOHUNTER

-

-

I think I would sooner club a baby seal!

I think I would sooner club a baby seal!

LOL THat was really funny! Im kinda the same, not a chance ... but a worthy suggestion.

-

Could you have added a section or pack to it for water container. You know a good bushman needs a little water container!! Nice looking bag, I like the rough look, killer piece.

-

Man looking at all these holsters makes me wanna go buy me a pistol tonight! Yall do some awesome work. I understand the time invested too. WOW.... Really impressive!

-

thats acool stamping! Lots of uses for Skulls. Good work.

-

Opinion... I would have disguised the makers mark in the florals not in the center.

What is a CAN anyways! LOL Sorry for the unknown item.

Looks like a son of a gun to detail though! Nice work, Corporal ?

-

Thats a really beautiful design. Ive been contemplating stamping out a belt or two myself. Nice and neat!

You mentioned the Oil soaking in. What is the reason and what is the oil. Im very new to leatherwork but like the leather I soak it all up!

Very nice tight work.

Steve

-

Ill check out the edging tutorial. I take it down smooth with a 120 grit drum sander and then use a piece of wood to burnish it and after about 5-6 minutes and a bead of sweat I think Im done, I cant get that glassy slick jet black edge. Ill read up on it and try it again. The only image pic is on the drill press and the edges are not finished then. They are the last thing I did except for the one like the strap, the front piece bottom and the loop. Sounds good and I appreciate the help.

I appreciate the input, makes it worth posting here.

Steve

-

486 people visited the LEATHERWORKER.net site today......

-

WOW thats a lot of time invested! Im sure ROZ is one happy camper! Its amazing to see the creativity on forums, you think you got it all down pat and then you open a forum up and all these ideas and designs show up. Looks like a lot of leather, last a lifetime! Thanks for showing.

Give us a tip you might have corrected to make something easier for construction, shortcut, Oopsy, Im glad I did that first!!!

STEVE

-

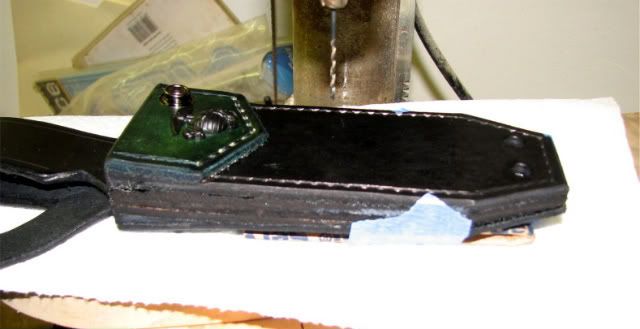

Alright guys, I beat myself up for the bandsaw blade delima and the MAIL RAN today.... brought me a package with my Black USMC Dye! Ive been working on a few designs for my buddy and the other week when we went diving I stole his knife out of the truck!! Im mean but its all good! He is going to get it this coming weekend wrapped in this new sheath! He is a Marine, served with President Bush as his detail. He has a lot of stories and just the real Bush temperment! Oh well we dive and flintknap together and just like a brother we have a freaking hell of a time when we get together! Im in my practice stage and I felt he wouldnt miss the knife ... if not he would be relieved to get it back in a better condition.

Decided a straight sheath, laminated, looped with a high handle, If you see the images he is also a County Deputy and my first design was a Star for the LEO! Then I was looking around Ebay and saw the Marines Ensignia and the next day went to the local Surplus store and grabbed a few for 3-5 bucks each, new or used. This is the Collar pin. A little Enlistment knowledge was that the Anchors are left and right, make sure you get the anchor headed where ya going not DRAGGING!!! Hey if its gonna be right better make it right! So for the offset of the USMC Black sheath and the black pin I felt a change in color for that section might set it off better. Good Move! Cant tell ya how many hours it has but I worked on it pretty much all day today off and on between the kids. I tried Olive Drab but I guess I didnt have the right combination and after an hour of being Dr. Jekyll I gave up and went deep green. I used a rag to apply it not the brush wanted it kinda thin. Gun Metal hardware and black stitch. Here she is!!!!!

The pin has a brass stud with screw nut, you will have to grind or cut it off and file or grind the nut a little to set it flush. Also you must sew the outter piece to the front BEFORE you glue them up! Lots of steps in these sheaths, Im getting closer to figuring it out! IM still having issues with drilling the sheath and grooving being the same. Im off a hair. You can see in the pic I use some cardboard to level the sheath off instead of drilling out the top or way off the bottom groove on the back. Im sure its a trick I just dont know yet but keeps ya thinking. Hope you enjoy it. Support all Law Enforcement and our Military, they work hard for our FREEDOMS!

STEVE BOHUNTER HOLLOWAY

-

Nice work I really like the Cowgirl one.... I remember those days chasing! LOL

-

I guess there are Rolls Royces in the tool world! LOL

-

Man thats what I like about custom work! Killer design. Seeing this gives me an addition to the design like you have. Appreciate the view. Ill break out the pencil and paper now!

SWEET knife too! Are the scales round filed to that design?

-

On the inlay piece. You have it glued to a piece under this then cut a viewing area to then sew it ontop of the glued piece? Looks freaking nice, Im gonna try this soon! You do some serious work there! Nice sheath and custom Holster set up!

-

You talking about the edge as in the burnishing edges? I started a fire on the large one watering after each burnishing, what could I do differently? All layers are cemented, hand saddle stitched. Tight as dicks hat band.

Thanks Steve

-

Hello, Im new to leather working. I started playing around with some knife blanks and now im into leather and its very exciting making awesome last forever items. My first sheath was a large knife project. Plain and simple no details but clean. Took me 9 hours! I had no idea the time invested. I see works on here and Im in awe at the hours spent making some of the master pieces. Gives me a new look at it!

Here is my second attempt, took more than 6 hours. Desided to try something different. Colors and details. I was going to put a strap hole on the tip thats why its higher than centered, once I finishe d the piece why strap around your upper thigh! LOL

If you dont have patience this isnt the hobby you want. Now all my buddies want one .. HA where were they a week ago!!

Thanks for looking.

Steve

-

When you set the snaps or rivets go slow taps and roll the tool around the head as you go, seems to work way better than Beating the (*&^ out of it! LOL I tried the hammer away first, rolling the tool works perfect and leaves a clean tooling. I wish I had a pistol to practice with. Im liking this leather working!

Steve

-

VERY CREATIVE!

When you say swivel knife technique. Can you explain your tools to us.. or me. Im very new but each bit of info goes into my mental rolodex.

Swivel knife, this still is unclear to me. The Blade as I received from Tandy on their beginner kit, is the blade supposed to be RAZOR sharp or just have the edge to crease the leather as the knife is pulled. Do you use the 3/8 inchish blade or the smaller blade.

When you painted/dyed the piece, did you use a resistor on any of the areas. What was your steps from a blank canvas from color to color paint brush or rag. Im going to post my two leather sheaths on this show and tell area and this is my first two pieces. Im learning but very paticular so bear with me!! LOL

STEVE " BOHUNTER " HOLLOWAY

-

Im new to Leather working and I havent even hit a stamp yet actually awaiting some material, but I know this is kinda a dumb like question but its something I have no idea about so Im gonna ask.... the purpose of the swivel knife is to tool an out line or create a crease, it is not an actual "CUTTING" knife? Nice work on the tools too. Clean!

Steve

Newest obsessive leatherworker to be!

-

I was thinking this was the proper leather but I had to ask since its a good chunk of change to "THINK" I was correct. Learn something everyday! Appreciate the info and links. Ill be sure to study up. Steve

-

Hello,

In as green to this as Im guessing you all were once. I happened upon some youtube videos and well.... here I am. Im usually pretty handy and after watching a few videos I was amazed at the abilities of some of these artists. Im a flintknapper, I make stone points and projectiles. Ive played with knife building and have always wanted me a nice bowie knife. Problem is they are really expensive and I like making stuff, so I felt its time for me to make one. Then Ill need a sheath.... ok Im back to why Im here again..

I understand the tools of the trade, watched and took notes of the basics. Purchased a few already. My question is this though.

What kind of leather am I looking for. I know its got to be thick, stiff, well what the heck is it called in the leather works world. Im looking to make a nice sheath. Ill probably make some designs too. I would like to buy some leather now. Its very clear that the dyed, suede like stuff isntr the ticket! I see some posts on here say that 4-6oz is good but some prefer 8-10oz for sheaths....

Is there a chart to show what an ounce scale is? How thick is what? This is my only question so I can buy me some stock to work off of.

If your looking for flintknapped stuff or have a question about this craft, whooo I can answer anything you got! LOL

Appreciate your time, I need some leather to work! I tried the saddle stitching tonight... good grief that a tedious process,,,, LOL

STEVE H.

BOHUNTER

War Belt

in Historical Reenactment

Posted · Report reply

Just amazes me the items people are able to make! Nice work.