-

Content Count

5,300 -

Joined

-

Last visited

Posts posted by Constabulary

-

-

not a too big issue, the spring just "holds" the thread. It should work with a weaker spring if not I may have a better one (I´ll email you later)

-

do you have a link?

-

I just googled what I can read on the face plate: Broad Street Machine Chattanooga Tennessee

Seems to be some sort of carpet tufting machine - or so.

-

Last picture seems to be a Singer 31 or 31K.

All theses machines are very old. The 12w most likely if the oldest from around the time when Singer took over Wheeler & Wilson. I think a 120 needle (metric) is what they all can handle but depends on the size of the needle hole in the needle plate.

Check the manuals for the machine. They should all be available online.

-

1 hour ago, Bmetalwear said:I have a singer post sewing machine 51w54 and doesn’t look nothing like that. If it is indeed a 51w54 then it looks to be missing some parts in front like the bottom thread roller and the felt pad retainer finger

Please post pictures of your machine.

The 51w came in 2 types and the earlier type looked a bit different and is based on a Wheeler & Wilson design.

This is how the earlier type looks like:

-

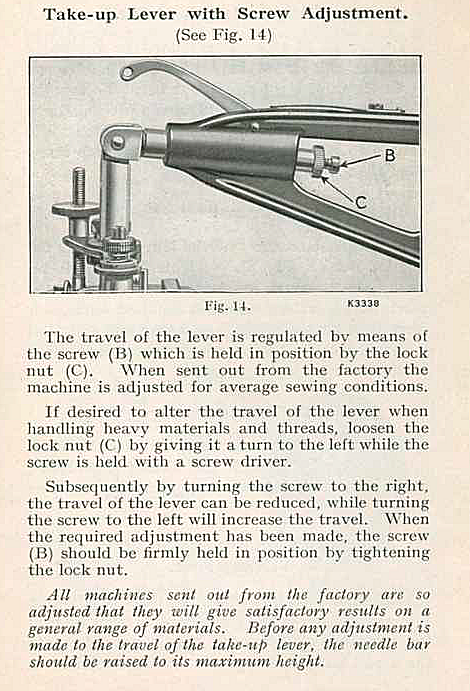

Has not to do with picking up the thread but what I noticed is that your Singer 29K51 has an arm lever from a very early Singer 29 that lacks the the adjuster for the thread take up lever. IIRC only the very early 29 came w/o this adjuster so your machine should have the adjuster shown in the below picture. However it should pick up the thread w/o this adjuster.

How is the condition of your shuttle hook, has it a sharp tip? Also, the needle holder can be moved sideways to bring the needle a bit closer to the hook.

Have you probably taken apart the gear box and not reassembled it correctly? That happens and the "drop out" gear box of the 29K51 is a bit special. I have restored only one single 29K51 (no longer own it) and there was no instructions for how to reassemble the gear box again so I did some trial and error and ended with the gear box and rack assembled like this - see 2nd picture - and it worked.

BTW - do you have manual for your machine?

One more question - how far did you take down the machine? Did you remove the top shaft or any of the cams on the top shaft?

-

I don´t know the 45w but on the few left stand machine I have seen and used (I have 145K1 left stand) the hand wheels turn away from you . No matter what watch the feed dog it should always feed away from you (assuming the machine has no reverse)

-

Thtas the case on all machines with drop feed except the feed dog just moves back and forth w/o dropping and raising (as on certain binder machines). How much it raises depends on how high the feed dog is set. Usually the feed dog raises by the 1/2 or up to full height of the feed dog teeth.

-

When the bushing is stuck it must likely is gummed up with old oil so I´d try some penetrating oil or kerosene (what ever desolves old oil) and if it does nor help apply heat with a blow torch and then try again.

-

12 minutes ago, DanishMan said:One thing, that puzzles me, is the presser foot. It appears to be fixed and to have no movement at all. Is this right?

Yes, its a needle feed + drop feed machine. The foot does not move. When the foot bar sticks out of the casting then it cannot move

-

Reduce the foot pressure and / or use a roller foot with smooth surface or rubber layer on the wheel

Not sure if this one fits your machine https://www.ebay.com/itm/142979318355

Not sure how your machine is set up machine but this would be an adapter for the above roller https://www.ebay.com/itm/145397360986

If your machine is set up with the flip aside roller foot already then there is also an optional adapter for using plain industrial presser feet (f.I. with a Teflon sole) instead of the roller foot

https://www.ebay.com/itm/143603134209

with installed foot:

https://www.ebay.com/itm/165883555629

If you have a 1 row needle plate and feed dog then this set could be helpful when using plain industrial feet: https://www.ebay.com/itm/143603162021

-

Seller here says its for the 47w as well (see description) - not sure if the belt for the 47w66 it different but I don´t think it is (not sure though).

https://www.ebay.de/itm/122465742879

I just checked the parts list and googled the number. This is the old style belt with metal braces - above belt is the new type made of rubber / neoprene.

However - compare the measures and number of braces and / or check with the sellers.

-

I have a revolving bush for this machine and other parts as well. I´m in Germany so shipping is not a problem.

-

I´m sure they are. I would guess the gears are probably old stock (or even old stock aftermarket). You don´t see many 110w's anymore and they have been discontinued for decades. I´m not sure but I don´t think anyone (even the Chinese) do not produce these gears anymore. Ebay is an underestimated source for old sewing machine parts and other old stock parts sometimes.

-

Ebay:

https://www.ebay.com/sch/i.html?_from=R40&_nkw=DRIVNG+singer+110w&_sacat=0

Keep in mind, the stitch length for the 110 was never really long. Do not expect that there was a gear for 5 SPI or so. IIRC then longest stitch was 12 SPI.

-

@MrHydez If the shaft diameter on your machine is 1/2" then a Singer 111 hand wheel probably could fit. Maybe you need some spacers to align it with the motor pulley (maybe not).

https://www.bmfwholesale.com/product/hand-wheel-singer-number-240545/

-

it can sew heavier - however test it before you buy it.

-

Do a forum search the Singer 78 and equivalent Consew 28 have been discussed here already:

https://www.google.com/search?client=firefox-b-d&q=singer+78+site%3Aleatherworker.net

Nice machine (I owned one. Bought just because I was curious but no longer have it) Not many parts are available for this machine so make sure it is complete and it sews. Compare pictures of other machines and make sure its all there. Needle is 135x17 / 135x16. As Alzilla said, you for sure want a different motor and / or a speed reducer.

I have a few files:

Singer 78 Beschreibung.pdf Singer_78_CONSEW_28_MANUAL.pdf Singer 78.pdf

-

Or just oil it manually. Don´t expect that there is a video or website for every single sewing machine.

-

-

BTW - the OEM Pfaff bulb is 62mm long and has a 22mm diameter just to give you an idea. Smaller bulbs may fit as well but I have installed a LED bulbs in my Pfaff 368 and it has a small diameter (16.5mm dia. and 56mm long) and it was a little bit fiddly to install them (grab, push & twist) because of the smaller diameter but it worked.

The OEM bulbs on my side of the pond usually were 12V but they come in 220/230V and 110V as well so depends on what your voltage is.

-

You need bulbs with B15D sockets. At least the Pfaff I know used them. There are also LED bulbs with this socket.

-

-

I have a complete lever w. knob and all parts for the 138. Not sure if is is 1:1 with the 238. Can post a picture later

WATER STAINED LOUIS VUITTON VACHETTA

in How Do I Do That?

Posted · Edited by Constabulary · Report reply

maybe some pictures would help to evaluate the damage.

keep in mind - you just get suggestions here maybe one maybe ten - maybe from pros maybe from hobbyist - at the end you are the one who decides.

I 2nd what NateLeatherGds wrote. If you can afford buying LV bags you also should be able to afford proper care or restorations. I´d would probably check with LV or one of they dealers if they offer some service.