-

Posts

5,687 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Constabulary

-

-

last pictures it tooooo small - not sure but seems the spring for the thread lever is missing (+ maybe the small stud and thumb nut?) - not sure.... See attached picture

if you have problems with imgae sizes check out "Image Resizer 3.1.1 for Windows" - if you have a Windows system - I´m using this for years.

https://filehippo.com/de/download_image_resizer_for_windows/

EDIT:

sorry - have not read your 1st post

Not sure where you looked but these springs are rather cheap:

https://www.college-sewing.co.uk/store/82219-CHECK-LEVER-SPRING-SINGER-29K

-

3 hours ago, Wizcrafts said:

Singer 111

venerable she is

-

I decided to sell my fully restored DVSG / BUSMC #6 HM. It is the head incl. bobbin winder + some some accessories - see below pictures for details.

This is the later model with stitch length adjuster near the driving cam !!!

I have restored it by my self and I striped the machine down to the core. I have touched very single screw! I thoroughly cleaned all parts and the casting incl. cast iron parts have ben cleaned in an electrolysis bath. Then I repainted everything in nice green / olive drab shade. Some parts have been replaced with New Old Stock parts I found in Great Britain.

Machine has the wax pot for the top tread and comes with the following accessories:

Bobbin winder, 1 shuttle, 2 bobbins, 2 presser feet (1 double toe on machine, 1 left toe extra) parts tin, approx 15 needles, some spare screws, oiler holder, bracket for flat bed attachment (the curved piece) some tools and a few other bits - I can also include an edge guide which it´s not OEM but I think you can make it work for this machine - I never installed it. See pictures. Oh - and there is a sharpening stone is for deburring the needle tips - just for the case. The brown thread on the bobbin winder is not included but I include some heavy polyester thread of approx size 207.

The squared piece in the upper left side (last picture) are for inside the wax pot AFAIK. Bobbin winder wax pot is included too - of course. I never have used either wax pot so they are clean. I put an extra tension unit on top of the bobbin winder because I had a thread stand for industrial thread cones and figured winding the bobbing works much better with the tension unit

I also have 2 PDF manuals - one original scanned and one digitally reworked.

Treadle stand is NOT included.

I take Paypal.

I can ship to USA,Canada and the whole European Union incl. Great Britain.

USA & Canada:

Price Including UPS shipping in a custom build cerate: $1750 / 1500€

EU & Great Britain:

Price Including UPS shipping or freight forwarder in a custom build cerate or on a palette: 1350€

Above Price expire on Jan. 31 2019 because right now I have a UPS shipping voucher which expires at that date. So shipping has to happen before that date. Later shipping will cost more.

If interested or you want to see more detailed pictures / need more information send me a PM or ask here.

I will post a YouTube video later.

-

39 minutes ago, Dufresne said:

Hi Evo160

any chance you have a source for a Repair manual for the Claes shoe patcher 20 I’m happy to pay for one. I’ve looked but no avail. I have a German manual but I can not read German. I’ve purchased parts and installed them. The machine has not sewn properly since.

Thanks

I have sent you a PM.

I´d recommend opening a new topic, post some pictures and explain the issues. I have some experience with CLAES patchers and a few others LW members too

-

importing a 110V motor from the US to Europe makes no sense at all. I haven´t yet seen this model on the continent but a similar motor is / was the HMC ZYT116. I had one but it made a permanent high frequency beeeeeep sound and that was so unbelievable annoying. I ended with a 750Watts Jack Servo from College Sewing. I meanwhile have 2 and a 3rd (and maybe 4th) one will follow soon.

-

good luck with that!

I know you want to avoid pulling the top shaft. But I´m not sure if it really is worth the effort and at he end not sure if it will work / last at all.

I know you want to avoid pulling the top shaft. But I´m not sure if it really is worth the effort and at he end not sure if it will work / last at all.

-

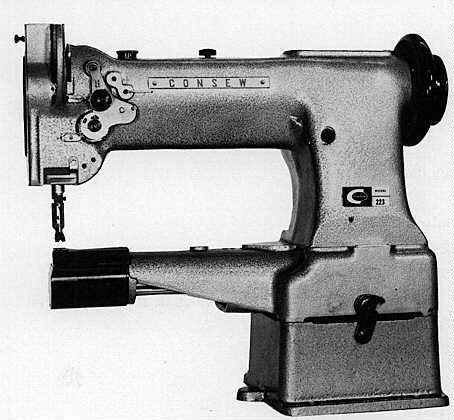

Seems the 223 came with 2 different stitch length mechanisms - one just as used on the Singer 153 (old type) and one with a stitch length / reverse lever (later type).

I would open the top lid and check what inside there and find out which type of stitch length mechanism is inside the machine.

But I think you are right seems someone "cobbled together" 2 different machines (see lever marks on pics 2 + hand wheel with coarse thread seems to be from the 1st type) - or - it is a custom build / modified machine but I cannot tell from your pictures.

I just looked for pictures:

-

Buy a servo motor + maybe later a speed reducer or DIY one! You will not regret it.

Value of a used clutch motor? Almost nothing because no one really wants them - maybe 25 - 30€ if you find a buyer.

College sewing is blowing out their NOS clutch motors for 28GBP with wires and switch.

-

I would go with a e-commerce shop software like "Modified e-commerce Shop Software" - its free - you only need the web space and have to adapt it to your needs.

https://www.modified-shop.org/

Not sure if they have an "english branch" but it has lots of templates you can choose from and you can check out some templates designs at their demo shop site:

https://www.modified-shop.org/demoshops

EDIT:

or check MAGENTO:

https://en.wikipedia.org/wiki/Magento

-

its a 29K71 clone with minor differences - not Singer made but probably better made than you other (29 clone?)

-

30-5 is a small hook high lift / long needle 30-3 is the large hook short needle variant.

3 hours ago, jimi said:Yes Folker, that would be good, thanks.

There you have it - 29K71 sewing approx. 12mm material with sz. 15 metric thread with 140 needle - okay I´m cheating for approx 0.5mm

-

I would buy the 29K71 mainly because of the parts situation. I´m owner of a restored 29k71 and have restores several other 29K models and Adler 30. The 29K71 is technically advanced and you have more options for making adjustments. The 29K71 can sew with a lower foot pressure whereas the Adler always has a certain and quite hight foot pressure due to the leaf spring. The 29K71 has a helical presser foot spring you can tune the foot pressure a lot better. Regarding high lift - belief it or not my 29K71 can sew 10-12mm thick materials - it just depends on the settings. This is no sorcery and I have not modified parts. I hoverer never sew materials this thick "in real life" but it is possible. The thing is you have to play a little bit with the position of some parts. I think Singer never explained well enough what their late model patchers are capable for.

I can post a quick 29K71 Video showing how thick it can sew if someone wants me to.

-

Picture tell more than 1000 words...

-

No matter the machine - you usually can but as you said sometimes it requires to bring the hook tip closer to the needle - meaning you probably have to move the hook saddle toward the needle. Just try it it will not hurt.

-

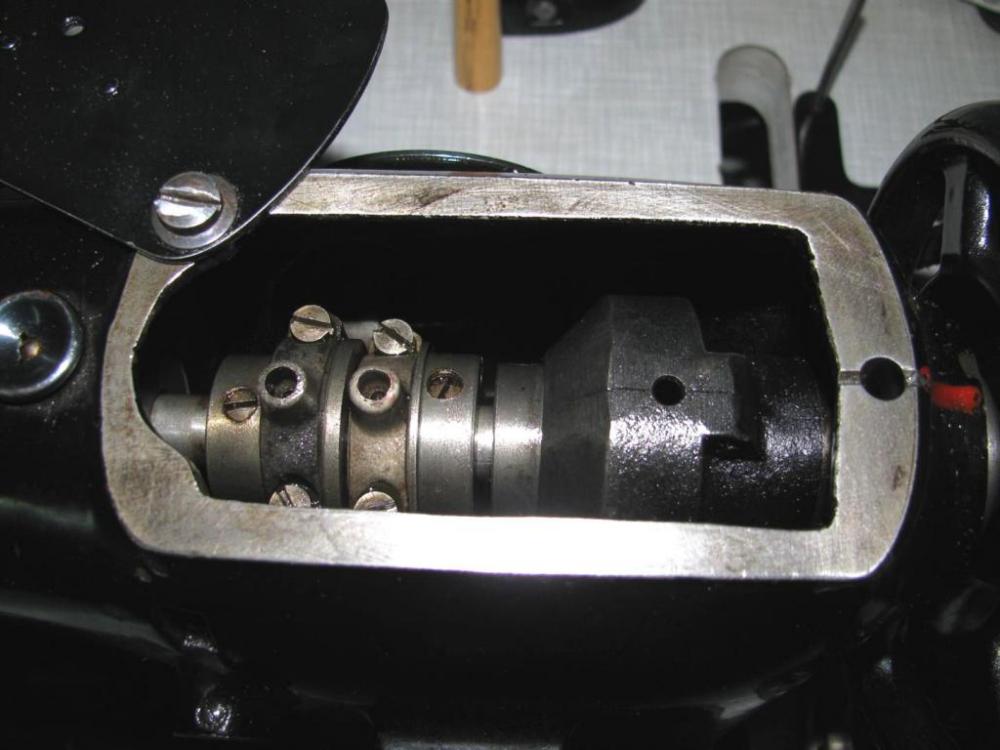

It is also possible that you have a dedicated binding machine - as far as I recall you can tell the difference by opening the top lid near the hand wheel, There usually is missing the 2nd drive rod which is controlling the up and down movement of the feed dog. If the rod is missing your feed to only moves back and forth.

You also can tell when you look on the underside. there is not drive rod attached to the upper rod.

Hope you know what I mean - I have to look for pictures....

Edit:

see pictures - I think you will notice the difference. Not sure if you have a binding machine but pictures tell the difference.

-

Since I have an interest in sewing machines I came across 2 or 3 of these motors they all didn't work properly and I figured it really was a waste of time an money trying to repair them (BTW I had no luck). When they run - great - keep em running - if they do not run just scrap them and buy a servo motor. It´s is a nice idea to "revitalize" old motors to save resources, avoid waste and to save money and so forth - I absolutely agree - but honestly if you invest more than $25 (not speaking of your time) it is not worth it. And you don´t know how long they will "survive".

I have tried several types motors and setups but the best solution for me (yet) is a servo motor + speed reducer. Lot´s of control, lots of torque (if needed) and you have energy.

My 2 cents.

EDIT:

check the timing belt of your Adler 67 - if it is brownish and brittle / has cracks - do not buy it - changing the timing belt on an Adler 67 class is a real pain. I did it once and and don´t want to do it again.

-

my plate is not an original 132K plate - I have modified a 96K table because the plate was so nice and vintage (original Singer actually).

The peg I´m using came form a different machine and I´m using the original hole of the former 96K setup cause I don´t wanted to drill new holes into this nice old plate. I´ll post some pictures later.

I´ll send you an PM bcs. of the drip pan.

-

Looks like drop feed variant w/o jump foot - then the machine takes the same presser feet as the Singer 45K / GA5-1.

BTW - do you need an oil drip pan & bobbin winder?

-

don´t know who typed it - must be decades old. I once found it in a lot of manuals I bought. You may need the "old" parts list (with old Pfaff parts numbers) to understand what parts they mean. I have an old 145 parts list but its too big to attach - if you need it send me a PM so I can forward it by Email.

-

sometimes its helpful to show a picture of the part because most people do not know the long Singer nomenclatures and parts number by heart and I´m sure just very few will check the parts lists - if at all.

You for sure have to check with a dealer for this part - maybe Keystone Sewing Machines in PA or Toledo Sewing Machines in OH can help you with this.

-

Rather a Consew 227 - maybe seller mistyped...

-

30-1 most likely - small hook short needle. You can tell from the position of the arm lever pivot pin that it has a short needle (pivot point on the right = Adler 30-7 / 30-5, pivot point on the left Adler 30-1 / 30-3) plus it has no raised housing and and on the last picture you see a pice of the hook - its a small hook.

- 30-1 small hook, short needle

- 30-3 large hook, short needle

- 30-5 small hook, long needle

- 30-7 large hook, long needle

It´s a light greenish hammertone paint. BTW - foot lift lever is broken off, needle plate holes are very worn.

-

I don´t think the shaft is stainless steel.

I haven´t pulled a top shaft yet and cannot support here but you at least have to remove all gears and all parts attached to the top shaft. I have a disassembling / assembling instruction for the Pfaff 145 - maybe it helps you a bit - the head is "quite" similar.

I have sent you the parts lists I have - I hope they help a bit.

-

Damn - thats bullshit!

Shipping a sewing machine from an "unexperienced" seller (in terms of shipping) is a 50/50 risk . I would always remove the hand wheel form the machine when shipping it or support the machine with styrofoam the way the hand wheel is free. And you at least need 1.5" styrofoam on each side (more is better) of the machine + it has to be packed real tight!

I have a parts list for a "new and old" 193. I´ll send them by email.

Pfaff once changed their parts numbers - what I have observed is that the old part number is part of the new part number meaning they added some digits as prefix and some digits as suffix.

The old number of the arm shaft is 10002 - the new number is 91-0100 002-05

College Sewing seems to have the shaft - seems this is the one but better check with them:

https://www.college-sewing.co.uk/store/9101000205000-ARM-SHAFT-GENUINE-PFAFF

German dealers might be cheaper but my experience is (ordered Pfaff parts once and requested prices from 10-12 different dealers) that CS necessarily is NOT the most expensive. Prices from German dealers varied by more than 100%.

BUSMC #6 HM (Head + Bobbin winder) - I can ship

in Old/Sold

Posted · Edited by Constabulary

Thank you I honestly hate to sell it, this was the best rebuilt I ever did - but - I have to be honest to my self, I will most likely never have enough work for this machine so the machine "rests" in the garage and is collection dust - that's not what it is meant for. I think since the day I finished the machine I have not sewn more than maybe 5 feet or so - sad but true. I barely sew heavy leather. I mainly sew webbing and canvas so it is like "pearls for the pigs". So it will serve a serious leather worker, saddle or harness maker better than me.

I honestly hate to sell it, this was the best rebuilt I ever did - but - I have to be honest to my self, I will most likely never have enough work for this machine so the machine "rests" in the garage and is collection dust - that's not what it is meant for. I think since the day I finished the machine I have not sewn more than maybe 5 feet or so - sad but true. I barely sew heavy leather. I mainly sew webbing and canvas so it is like "pearls for the pigs". So it will serve a serious leather worker, saddle or harness maker better than me.

The stand can be sold separately but It cannot be shipped over the pond to the US or Canada - I´m sorry! Due to size and weight the stand can only be shipped inside the EU by freight forwarder or we talk about personal delivery (depends on location) or pick up.

So if someone inside the EU is interested in the stand drop me a note. It has an attached work plate and has the original heavy cast iron motor mount.