-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rhinez0r

-

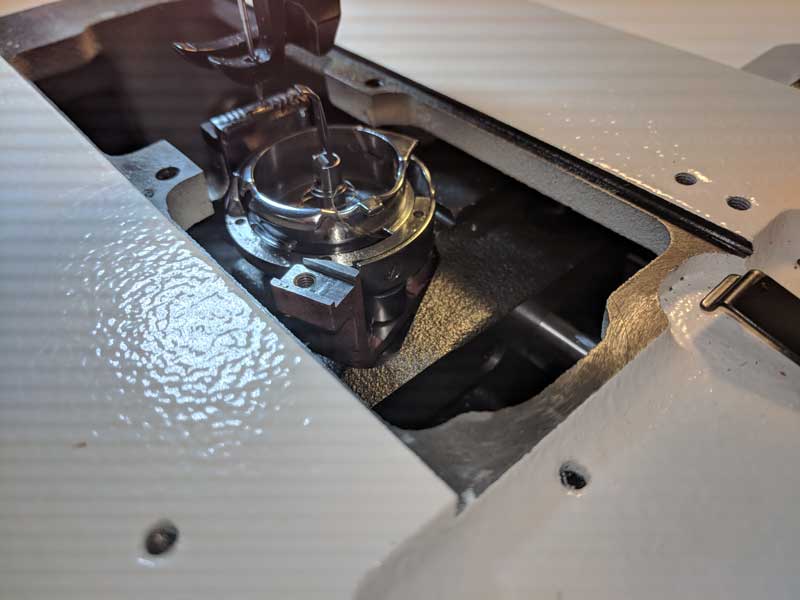

juki JUKI 1508/LU-563N - I can't remove the bobbin case?

rhinez0r replied to rhinez0r's topic in Leather Sewing Machines

Thanks all - we used a pair of pliers to grip the bobbin case and turn it. Just a small piece of thread stuck under the case. Appreciate all the help. -

Selling Techsew 2750 pro - ideal for heavyweight items such as leather and canvas. I've had it for 3 years, good working order. Local technician looked it over and it's good to go. You must pick up from our workshop. Asking $2,000 CAD, Must pickup from my workshop in Nelson BC, Canada. Features: - Compound walking-foot feeding mechanism - Sews up to 3/8" thick leather - SmartServo-NP needle position motor - TLG laser guide - Swing down roller guide - Flatbed table attachment - Includes table & adjustable speed SmartServo-NP needle position motor

-

Better safe than sorry, thanks Bruce. I will give them a call and update this thread with my experience

-

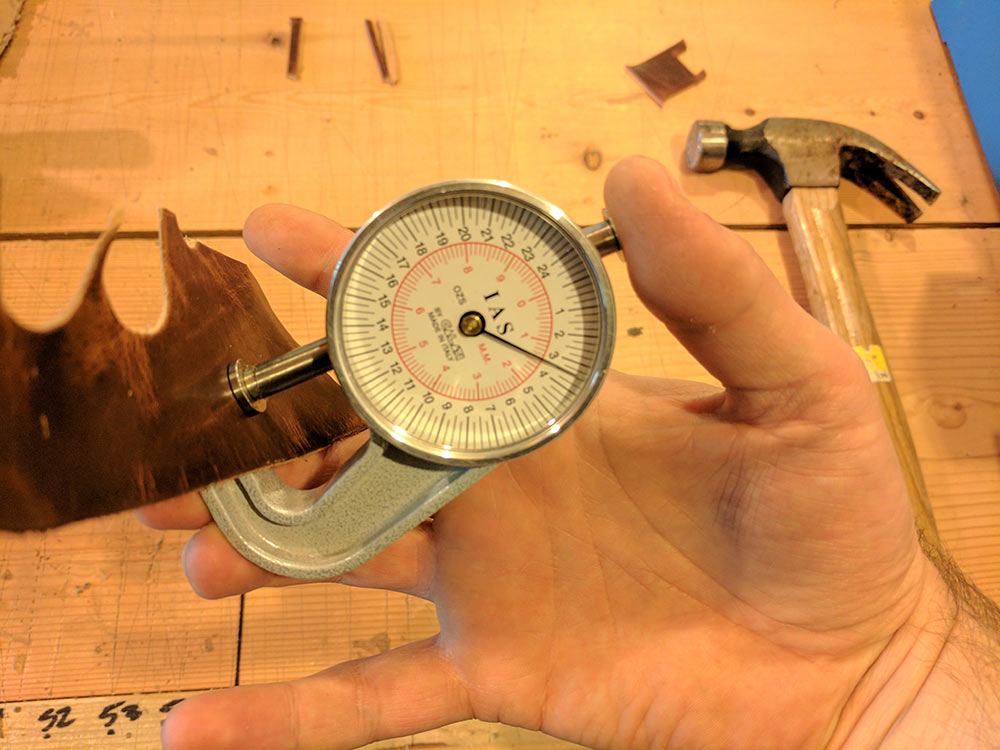

Thanks for taking the time to write that thoughtful reply Bruce. You certainly made me appreciate this beast more. I'm primarily splitting weights of 5 and 6oz leather, my understanding is that the roller bars should be adjusted for this type of work. Could you show me where the top screws are located? I only have oil wells at the top and bolts everywhere else. Here are some more pictures:

-

Just had this splitter delivered today, it's brand new and adjusted at the factory. I'm having some problem splitting veg tan/dublin. I gauge the leather at 6oz and I want to skive it down to 4oz or 5oz. Yet, I can't seem to get it to feed through the machine.The only way I can feed is if the splitter is gauged to 3oz or lower. Machine didn't come w/ instructions, nobody is in their office at Landis and all I can find online are Landis 30 instructions.. but they are a bit obtuse for me. Anybody have suggestions?

-

Hey thanks! The motor is still under warranty, I think I isolated it to the circuit board. The RPM can't be adjusted, we took the safety plate off and the spinning wheel just rubs against the brake pad and almost starts to smoke. Since the sensor isn't "sensing" and the RPM dial isn't working I must assume it's a circuit issue. I'm actually in the market for more thread and supplies, so I may hit up Masons either way =)

-

Control arm ok, nothing slipped or bent. I am wondering if it its an electrical issue with circuit board. Anywhere we can find more information?

-

Anyone have experience fixing a variable speed servo motor? It was working fine yesterday, but now when I turn on my machine it won't stop running. It's a 550w variable speed servo motor.. should I just get it replaced?

-

I picked up a C.S. Osborne 86 Splitter, but the blade is dull. So I bought some DMT DiaSharp Diamond Stones to fix that problem. Only issue is.. I can't seem to get the blade sharp! I'm using the 8" 600x, 1200x and 8000x Diamond Stones. Any pointers?

-

Hey folks, any suggestions on what kind of machine I can use to split 5 & 6oz leather down to 3oz? Would a Cobra Class 14 work?

-

Hey all, I've been doing my watch strap ends with the Tandy Safety beveller, but I wonder if there's a better way? I skive the ends where they wrap around for the pin and buckle. Could I use a machine like this splitter to get more uniform skives? I'm working with 4oz CXL as well. Any thoughts or suggestions?

-

Noticed that it looks almost identical to the Tandy:

-

Does anyone have an opinion on this? http://shop.raphaelsewing.com/index.php?main_page=product_info&cPath=95_96&products_id=838 Looking to pick one up, but there isn't much information out there.

-

I'll try that! Thanks & Merry Christmas

-

I'm using a techsew 2750 pro, the needle is 135X16DIA and thread 207

-

The bottom of my leather always looks like this when I sew, any idea what's causing this? Any way to solve this problem?

-

I was hoping to get this sorted during the weekend. I took a trip to Home Depot and found a similar thread/size (it's m6) so that should do it for now. I'll contact Techsew and see if they can send me some spares. Thanks for all the help everyone!

-

Yep - looks like it! Thank you

-

I've had good luck with Maverick - Tannery Row is always worth the wait though. Anywhere else and companies are just going to gouge you.

-

Hey folks, I ended up stripping a screw on my Techsew 2750 and I had to remove it with a drill. I took it to a few hardware stores in the area, but nobody seems to carry this (or could even identify it). Could someone help me out? Maybe I could get this online? It's a flathead screw. Here are some pictures:

-

Looking At A Techsew Pro 2700 And 2750

rhinez0r replied to rhinez0r's topic in Leather Sewing Machines

Incase anyone is interested, here's a reply I got from Techsew: Now I just have to make room in my studio -

Looking At A Techsew Pro 2700 And 2750

rhinez0r replied to rhinez0r's topic in Leather Sewing Machines

This is good to know - thanks. -

I've been hand-stitching my products for a long while, and we're at the point where we can no longer keep up. Jill and I are looking at getting a hold of an industrial sewing machine for our studio and we've narrowed it down to a Techsew Pro. Mostly because of the laser - we're afraid we can't stitch straight lines worth a darn. We're also in Canada and don't want to pay the extra import fees importing from the USA. Anyway, these machines have come highly recommended to us by various leatherworkers. I'm hoping someone could tell me the difference between the 2700 pro and the 2750 pro? From what I gather it's just the large bobbin? We primarily sew small leather goods like wallets, I figured a 441 is overkill for our work. I'm a TOTAL newbie when it comes to sewing machines, so any advice is appreciated.

-

How much are the 500m rolls?