-

Posts

24 -

Joined

-

Last visited

sulla's Achievements

Member (2/4)

-

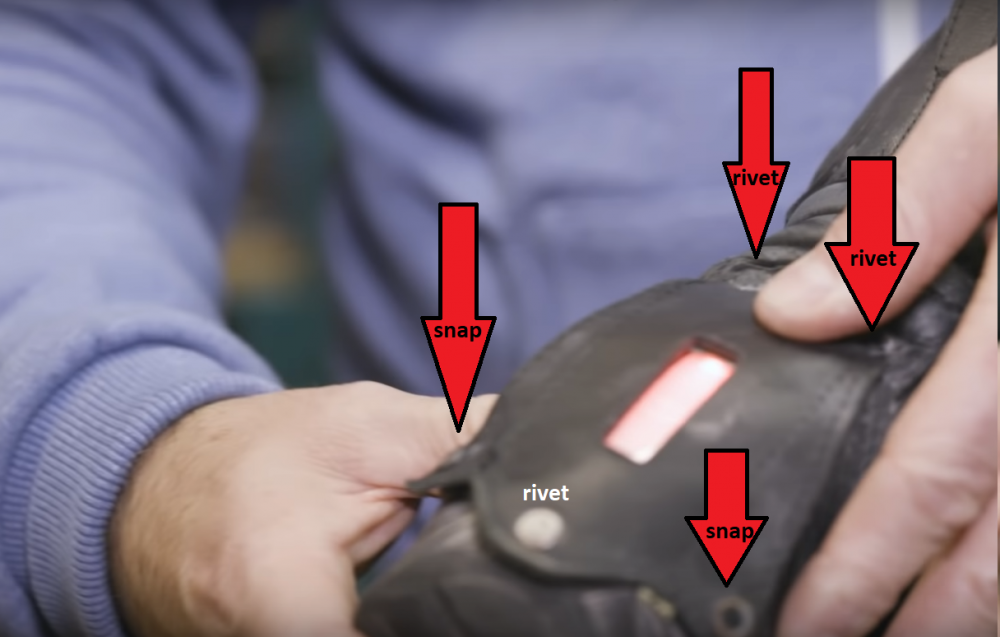

I am trying to replicate this extra heal flap as used on boots in the TV show The Expanse. I was wondering how you might get into the boot heal so deep to put in snaps since the shoe is closed and using a sturdy table to set the punch base on is not possible. I've thought about clamping a piece of flat stock steel in a vice as a sort of narrow extended anvil for getting in there. Or even using my cobblers shoe anvil. Any suggestions? Note: the lowest rivet is decorative and part of the flap only.

-

Is this just a Yamata FY5318 with a "Chicago Electric" logo on it? Or is it a clone or something?

-

I have an opportunity to pick one of these up used for $400. Was wondering if it would sew leather up to any particular thickness? It is still possible to get parts and needles, etc for it? I usually sew veg tanned up to 8 oz, and soft chrome tan buffalo hide up to 10-12 oz. for turn shoes. Thanks!

-

Help understanding this applied edge trim for turn shoes, please.

sulla replied to sulla's topic in How Do I Do That?

Thanks! I've used that stitch too many times to count when sewing cloth but never with leather. I hadn't thought about that with a glovers' needle. Here is an image of the construction from a book I have. I wonder if in step 'c' the holes in the upper are pre-punched with a strait or curved awl, sewn through with a strait or curved needle, or something else? The books offer no further suggestions as to method of construction for this type of seam. -

I make turn shoes for mostly reenacting purposes. I have decided to up my game by doing some edge trim on a two-toggle Scandinavian turn shoe. The trim is skived to about half or 1/3 thickness on one side. The thicker side of the trim is first butt-seamed to the edge of the upper leather. Then it is turned over so the thinner skived side is inside the shoe and is then stitched to the inside of the leather upper with a sort of hidden whip stitch. These whip stitches do not show through the leather. I understand how to do the butt stitch, but I was wondering if there were any tricks or techniques or even special tools for this. I have some shallow curve bladed awls but have not used them for this purpose. (first image is a process photo by Simurlan. The images of completed shoes are made by Alexey Nikifovorov. )

-

Got 2 new free Singer sewing machines, your advice sought.

sulla replied to sulla's topic in Leatherwork Conversation

Thanks all. I was able to sew linen and some heavy canvas with the 99K with a 110 needle and some Coats "Extra Strong" Upholstery thread. Haven't tried leather yet. The other machine is definitely a clone. It was made in Japan. I don't think it says occupied Japan, but I will look again when I get home. -

Got 2 new free Singer sewing machines, your advice sought.

sulla replied to sulla's topic in Leatherwork Conversation

Thank you for the information rejerome. I went looking after I posted this and found out that this is indeed the 99K. even found a manual to download. Here's hoping this is the one that has all it's parts and still runs. -

Got 2 new free Singer sewing machines, your advice sought.

sulla replied to sulla's topic in Leatherwork Conversation

I make shoes like these among other things. The ones I made out of this line-up are the pair second from the left, the brown and burgundy with the black soles.. -

My sister-in-law picked these up at a flea market sale and gave them to me. Anyone know if either will sew leather if I get them running? I was told that one of them runs but the other needs work. Not sure which as I got them late last night and haven't had the time to plug them in. Alas, neither has a walking foot. I most often make shoes and commonly work with 5-8 oz chrome tan bull hide (often skived to 1/2 thickness for seams) usually bonded together with Renia aquilum or Renia all purpose cement or sometimes barge. I also use 2-3 oz. veg tan leather used as toe and other reinforcing pieces in shoes.. Here is the second one.

-

Here is an example of one on a throwing tomahawk. I use the same style covers for my Viking boat ax and camp axe.

-

Talk about not replying sooner. I can get you some pixs. Still need them?

-

Need about 10 each 3-5mm striaght stiching punches, make them?

sulla replied to sulla's topic in How Do I Do That?

Awesome, Masonry Nails! -

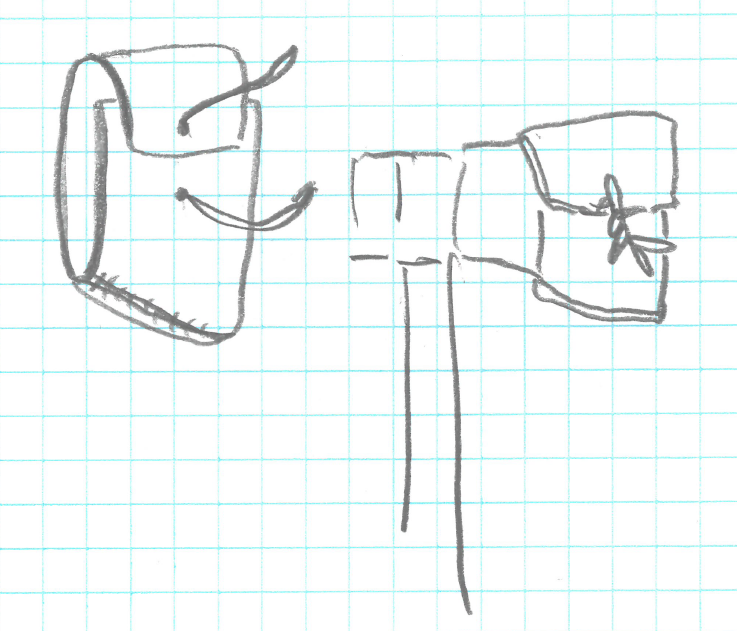

This is an example based on a Haithabu find. I tried looking for a picture of the leather covers I use for my Viking camp axe and Viking boat axe, but I couldn't find any, sorry. Here's a drawing. I can take some pictures of mine when I get home tonight if you wanna see them.

-

Need about 10 each 3-5mm striaght stiching punches, make them?

sulla replied to sulla's topic in How Do I Do That?

-

I have the opportunity to teach a class on making some simple Roman period sandals to a class of about 10-15 people. I have all the tools needed, lacing needles, mallets, punch boards, etc. All the tools, that is, except for some small flat hole chisel style lacing punches. I need single prong or chisel shaped 3mm-4mm lacing punches in about 2 weeks time. I have one or two but having the class share would take for ever. The available Chinese punches take too long to arrive. My local store has 1 or 2, and can order more, but is looking at similar lead times. So I am casting around for ideas. I thought about using those long flat head screw driver bits like you use in power drills and sharpening them, getting some round stock, hammering it out and grinding it sharp, but I am not experienced and don't want chisels breaking or bending while the students use them. The leather will be in the 3-5 oz. range. Soft veg or oil tanned stuff. Any ideas? Maybe sharpen some nail punches into flat thong punches?