-

Posts

15 -

Joined

-

Last visited

About n866

- Birthday 01/06/1981

Contact Methods

-

Website URL

N/A

Profile Information

-

Gender

Male

-

Location

Dayton Ohio

-

Interests

Leatherwork, hunting, fishing, & anything with a motor!

LW Info

-

Leatherwork Specialty

Learning lessons the hard way!

-

Interested in learning about

Heavy Duty Sewing Machines & all aspects of refining my leather craft!

-

How did you find leatherworker.net?

Google searches

n866's Achievements

Member (2/4)

-

Awesome thanks for the feedback!

-

Because all my friends know me as "the leather guy" I get a lot of requests for anything leather related. Sunday I had a friend call me up asking where he could take his professionally tanned deerskins to have things made (gloves, jackets, purses, etc.). I guess he had them tanned over the years by a place from Wisconsin or Minnesota & they used to make garments, but they are long since out of business. It sounds like he has over a dozen, and would like to have a couple nice things made from them. Do any of you have recommendations for a place that makes high quality goods from your deer hides? I found a place on-line here in Ohio that says they do just that, but I figured I'd ask some of you for your opinions as well. I know he'll want high quality. http://www.custommadesportwear.com/ Thanks for your time!

-

Awesome thanks for the support!

-

Good morning all! Hope everyone had a good Thanksgiving holiday here in the states. I have been starting to get my Adler 205 ready for the servo motor conversion. I also wanted to by an edge guide. I see one of the ones I had been looking at was on a Cyber Monday deal from Amazon. I've read through a dozen threads on here, and I'm having trouble identifying if this will work on my 205? I see some threads where people used an adapter for a similar style, but I'm really confused due to my lack of experience. Any help would be greatly appreciated. https://www.amazon.com/KUNPENG-Suspended-LU-1508-Industrial-Machines/dp/B0774FZWTN/ref=sr_1_5?crid=WVCAULB6O7HQ&keywords=suspended+edge+guide+for+adler+205&qid=1669649898&sprefix=suspended+edge+guide+for+adler+205%2Caps%2C67&sr=8-5 Thanks, Nate

-

servo motor consew 225 Which servo motor to buy for consew 225

n866 replied to photo2u's topic in Leather Sewing Machines

What servo motor do you use? -

Thats a good idea!

-

Thanks Ken. I'll be looking into that as well.

-

Silky, I've got a 60 gallon Snap-on that should handle it just fine, especially for the small volume I plan to run on it, but like I said I'll likely go to servo especially since I plan to move it inside. The coupe is my 47 Plymouth coupe. It's just a dirty old hotrod that's been in the family for a long time. Small block Chevy & a Ford 9" It's running and driving but long over due for me to go ahead & really blow it apart & start the lengthy task of the sheet metal repair! Thanks Jim. He's on my list. I'd like to try & support an Ohio business if possible & of course its great to have a resource for questions too!

-

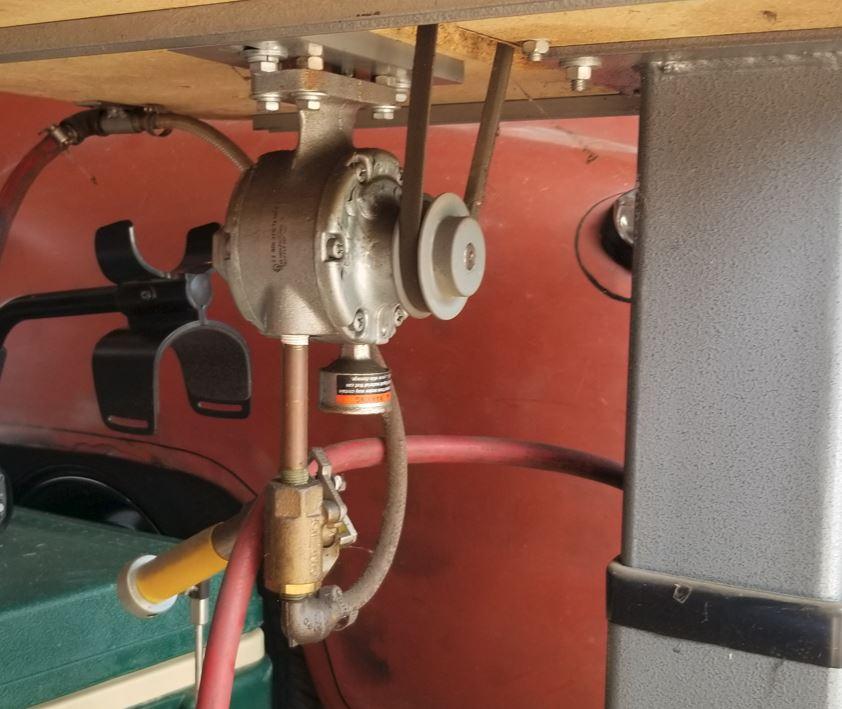

So I stumbled into a deal I couldn't pass up on a 205-370. It belonged to a friends grand father who passed 3 years ago. The story goes that he got it as a replacement for an older singer machine that he had modified to run on air when his shop burnt down. His insurance replaced it with this one because it was the only pneumatic machine they could find. I'm embarrassed to say how cheap I got it, but they were very happy to see it go to someone who could use it because he set it up & supposedly it has less than one hour of run time on it. I never thought it would be in my price range to own a real 205 so I have never done much research on one. I'm VERY inexperienced with any machines much less one of this caliber. Of course I was not looking for a pneumatic machine, so I plan to set it up with a servo at some point, but I am planning to grab a pressure regulator & set it up in my garage just for giggles. I've been reading several threads on here about 205's & watching a lot of youtube videos. If anyone has any suggestions, (or any other resources or recommended threads on here about set up, maintenancing, tips or tricks, etc) I would really appreciate the support! I'll be slowly chipping away at it because its hotter than hades out in the garage right now, and I've got some other work to get caught up on in the next month or so anyway. I'm really excited to get started playing with it & look forward to learning a new skill set. I'm positive I'll be investing in some more hardware, guide plates, different style feet, etc if necessary. thanks in advance!

-

Consew Model 225 Should I buy! Will it work?

n866 replied to n866's topic in Leather Sewing Machines

Well I pulled the trigger and I'll be going over to help him dig it out of his shop after I get back from vacation next week. Thanks everyone. I'm sure I'll be back with questions! -

Consew Model 225 Should I buy! Will it work?

n866 replied to n866's topic in Leather Sewing Machines

Great video by the way! Wish they were all that nice. -

Consew Model 225 Should I buy! Will it work?

n866 replied to n866's topic in Leather Sewing Machines

Awesome everyone thanks! -

Consew Model 225 Should I buy! Will it work?

n866 replied to n866's topic in Leather Sewing Machines

He told me not only would he run it but he would tech me to use it the way he has it set up for the upholstery. Thanks for chiming in! -

Consew Model 225 Should I buy! Will it work?

n866 replied to n866's topic in Leather Sewing Machines

ok I meant to post this in the leather sewing machine forum, so if someone wants to move this feel free! Sorry! -

Hi everyone I'm a long time lurker, and almost always find my answers with out posting. You guys are great with all the support you put out there. I've found an old Consew 225 from a local guy who used it to do some upholstery work. I would be looking to use it as my first machine. I do a lot of wallets with about 4oz liners and more like 5-7 oz tooled outers, but have been wanting to be able to stich some guitar straps, maybe even a belt. I imagine that may be stretching it. As far as I know its just a clutch motor, and I may need to make some upgrades but I believe I can get it somewhere between 2 and 300$ and I can see it run before I buy? Do any of you all have any experience or pointers before I pull the trigger. I think it may be a little underpowered, but with some upgrades I think it may work? I've considered doing some lighter bag type Thanks all!