-

Posts

31 -

Joined

Recent Profile Visitors

2,003 profile views

medion's Achievements

Member (2/4)

-

Hi all, I do a lot of production sewing which involves wide hems, which I currently do with two passes on a single needle Juki. I'd like to upgrade to something more efficient for this task, and I'm looking into long arm compound feed twin needle machines. From what I can gather however, most needle gauge adjustments max out at 24.4mm / 1" - however I am hoping to achieve something like a 32mm / 1.25" gauge spacing between the two needles. Is anyone able to recommend or suggest machine(s) capable of this? Cheers!

-

Thanks everyone - it was the safety clutch being activated because the hook could not rotate due to being jammed deep underneath with thread and having no oil after sitting for a long time. I was able to pry it apart, clean, oil and then it all started working again and I was able to continue on doing some pre-war vehicle upholstery repairs. Thank you!

-

Hi all, I am looking at this Pfaff 145 for my father in law - I cannot for the life of me work out why the hook is not doing full rotations. I'm not familiar with this machine, and I was hoping someone could take a look at the following two videos and possibly provide some insight? I understand the throat plate needs to be in place for it all to function, however I've taken a video with and without to try and illustrate the issue: https://www.dropbox.com/scl/fi/b5cdijblzmo7e3nyp4diu/IMG_3732.MOV?rlkey=ewo531ra41pzn97x6ypz0w283&dl=0 https://www.dropbox.com/scl/fi/49sz9e76468dgcoe75aga/IMG_3734.MOV?rlkey=6mz092r091xtutxzlwq87som2&dl=0

-

Hi all, This is a bit off topic as it's not a leather machine per se (this is my only non-leather sewing machine), however I know there is a wealth of knowledge and industry here and I was hoping someone might have an answer. Does anyone own a dedicated blanket stitch / crochet stitch machine - most commonly built by Merrow? I own one for whipping blanket edges. I currently use a 5/2 weight cotton yarn for this, however I am noticing the yarn I use often has knots in it, which is ripping through my needles. Has anyone worked with these machines and able to recommend what kind of yarn/brand/weight is commonly used in production blanket edge stitching? Cheers! Medion

-

Very frustrating loss of bobbin tension mid-stitching, help!

medion replied to medion's topic in Leather Sewing Machines

I'm also noticing something else which is contributing to inconsistency - thread spooling off my thread cones is not smooth. I can feel it jerk, especially as it spools off the bottom, as if there is a minor stickiness factor in the cone thread. Is this a result of a bad batch of thread? Or? -

Very frustrating loss of bobbin tension mid-stitching, help!

medion replied to medion's topic in Leather Sewing Machines

Thank you everyone for your help - so, for future people having this issue, it seems like an increase in needle sized has likely resolved it in tests. I need to run a few actual wallets now, however, with scrap it looks like it's resolved. I'm running M40 thread needle 130/21 -

Very frustrating loss of bobbin tension mid-stitching, help!

medion replied to medion's topic in Leather Sewing Machines

This actually looks like it's not an entirely uncommon problem -

Very frustrating loss of bobbin tension mid-stitching, help!

medion replied to medion's topic in Leather Sewing Machines

Thanks, I'll take a look! Honestly, I have so many tension issues with this machine, none of my other 3 machines cause me so much drama... I feel like I'm constantly fixing a hangup or battling a bizarre issue like this... -

Very frustrating loss of bobbin tension mid-stitching, help!

medion replied to medion's topic in Leather Sewing Machines

Thanks very much for all these ideas - I will try swapping in a new needle to start with and see how I go. With regards to twisting thread, I wonder if the thread is twisting when I round the corner? My corner rounding is done by spinning the wheel by hand, as I cannot reliably control the clutch and round the corner. So, I sew up to the corner, stop, hand crank and turn the corner with the needle down and the foot up. This is how I've always done it, and I've rounded literally hundreds of corners on hundreds of wallets and other objects, but for some insane reason this is now plaguing me... Anyway, let me try a needle change and changing the bobbin direction. Thanks again. -

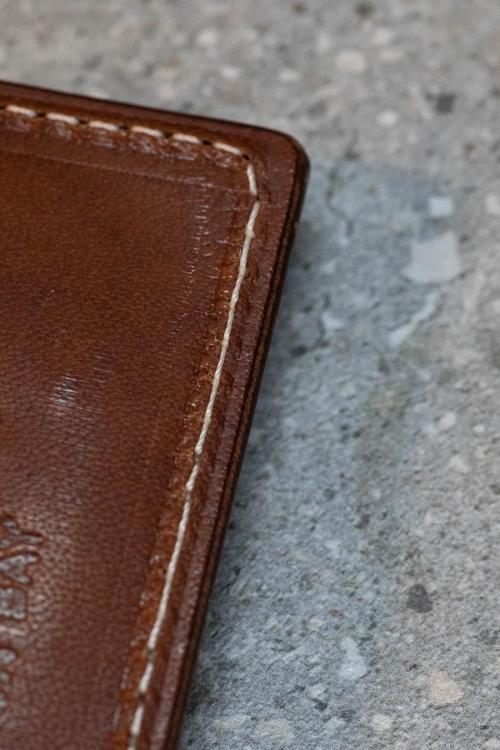

Hi all, I'm working on 10 wallets and 3 of them are having the strangest loss of bobbin-tension after rounding the corner. I cannot work out what's going on, and I've re-worked two of them hand-winding through the existing holes, to the same effect. I cannot for the life of me work out why this is happening. It's on a JUKI 1508 NH - any thoughts on what's going on would be so very helpful! Cheers, Medion.

-

The honest truth, is that I like working with unusual and high performance materials... There is no reason other than that I do currently use v69 right throughout my wallets though, it has held up well so far - what are you using for your main wallet stitch line if only using v69 for wallet internals? The honest truth, is that I like working with unusual and high performance materials... There is no reason other than that I do currently use v69 right throughout my wallets though, it has held up well so far - what are you using for your main wallet stitch line if only using v69 for wallet internals?

-

Hi all, Does anyone have any input on what could be considered the strongest modern machine sewable thread for leather? I currently use a bonded nylon #69 thread which is fine, but I do wonder what the strongest machine sewable thread may be, I'm thinking in terms of Kevlar and Dyneema (or others?) - does anyone have experience with high tech threads? I understand there comes a point where the thread is significantly stronger than the leather, however I'm wanting to avoid that part of the discussion. -p

-

THANK YOU everyone - you're all right, it is the clutch being in brake mode when the machine is stopped. If I run the pedal very lightly, the stiffness disappears - thanks so much, I was getting all worried about having to fit a new motor or something

-

Hi all, I have a Pfaff 335 - the older style, image attached as an example. I'm having an issue which appears to be getting worse, whereby the motor is hard to turn/sticks. It's not the machine, if I take the belt off the machine itself turns over smoothly. That being said, the clutch/motor still works perfectly fine, and you wouldn't notice it if you didn't hand crank the needle into position or around tight spots. I'm just wondering if this is normal behaviour/the motor is wearing out/bearings are toast/or other. Am I not doing something maintenance-wise? My other two machines are much newer with servo motors so I have nothing to compare - I also live in a remote place without access to industrial machine mechanics. Any help greatly appreciated! Cheers!

-

Cheers - sorry to be a pain, but are you able to show me a link to the bits you changed on your machine?