-

Posts

32 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://www.workoutsandbags.com/

Profile Information

-

Gender

Male

Recent Profile Visitors

1,589 profile views

dgkfit's Achievements

Member (2/4)

-

Hello, Thank you all for your help in the past. I have a Cobra Class 4 with all the premium accessories. I have been using it to sew nylon fabric to make exercise gear for almost 3 years now. I am probably going to end that business soon. The machine is paid for by sales. I need to decide what to make with it now. Let's assume that it will be made of leather. But I don't know what to make with it. Even tho I am from Texas, I don't think another saddle / tack maker is needed. And, I don't speak the "language" of those who use that stuff. I am thinking about shearling vests, making one or more for myself, and seeing how that goes. Also, I am thinking about making dog beds. But back to the leather. Where can I get both ideas and instruction on how to do leatherwork? Thank you Dale Workout Sandbags

-

Foot Lift sticking problem with 441 clone

dgkfit replied to dgkfit's topic in Leather Sewing Machines

Hello all, I think i have it fixed for now. I loosened the screw that holds the pivoting part with the fork, and got the fork to go over the coil at the end of the thick wire that goes on down inside the machine. (That is the internal linkage) Again, the parts manual gives no names I can find for these parts. The " upper end of the thread tension release arm" DOES go between the "thread tension discs" when i step on the lift pedal. Steve at Leather Machine Co told me to adjust the " foot pressure adjustment screw on top of the machine" way down because the feet were slipping on slippery ballistic nylon fabric. So, that raises the question: SHOULD I ADJUST THE BANANA SLIDE TO THE TOP POSITION FOR THIN FABRIC?....if so, and then should i loosen up the screw that makes the foot pressure spring so tight? Thank you all again....I think I fixed it. I will call Steve/David if it needs more fixing. Dale K -

Foot Lift sticking problem with 441 clone

dgkfit replied to dgkfit's topic in Leather Sewing Machines

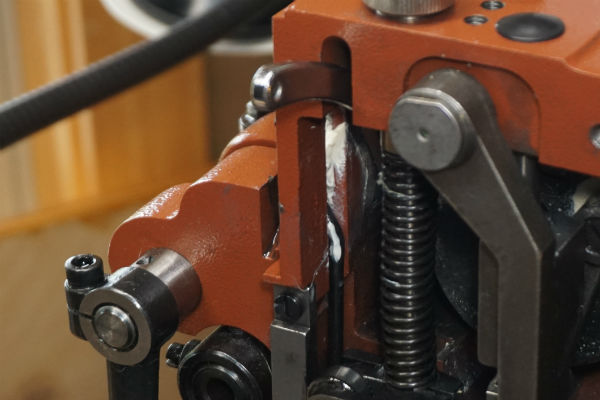

hello all, i took the end plate off and oiled everything that moved. that included some pistons that go up and down when the feet are lifted. then, when i went to put the thing back together, and put the fork over the knob that connects and completes the connection, the disc that goes around the bent rod inside the machine came off. i dont know how to re-connect it. it is a mess. i looked hard in the parts list to find names for these parts, but could not find them. fotos are below. thank you for your past and future help.....dale -

Foot Lift sticking problem with 441 clone

dgkfit replied to dgkfit's topic in Leather Sewing Machines

hello floyd, thanks for your input. i didnt take the end plate off, but stepped on the foot lift, locked the hand lock, and stepped on the foot lift again. the hand lever dropped. this is after i oiled the center bolt on top/end. i will take this up again tomorrow. thanks dale -

Foot Lift sticking problem with 441 clone

dgkfit replied to dgkfit's topic in Leather Sewing Machines

hello uwe, thank you for your help. i oiled the bolt that goes up and down inside the lockscrew that adjusts the presser foot height. that helps alot. we shall see. your "hiding in plain sight" input helped me look at that. i will sew tomorrow. thank you and i will reply with more....dale -

Foot Lift sticking problem with 441 clone

dgkfit replied to dgkfit's topic in Leather Sewing Machines

hello wiz, bob, and uwe, thank you all for your rapid reply. i will try to answer all your questions, and try what you recommended. it is a cobra 4. i bought it new, only because its dealer was the closest dealer to me. but it has been a good machine, and the service has been fine. 1 it will stick up no matter how it was put there, foot pedal or manual. 2 the recommendation was that i take a dremel and motor-file off some of the end of the lever's knob, which attaches to the fork on the back / end of the machine. i did this some. 3 the big presser foot pressure knob is adjusted way down tight for the thin fabric i sew. is that making the foot stick in the up position??? 4 it has been a while since i oiled inside the end plate. i had a machine mechanic come and try to fix the problem, last fall, but he hasnt totally fixed it. and, he looked inside the cover plate. which place inside there should i especially oil to treat this problem? thank you dale k -

Hello, Your help is needed. I have a 2 year old 441 clone, one of the popular brands. It has a chronic problem. The mechanism that lifts the presser feet to remove material from under the feet and needle sticks, usually in the UP position. I have done what the importer says do, and it still does it. Is there any advice out there as to how to fix it? Thanks Dale

-

Hello, Thank you all for your help in the past. I have a 441 clone. I have watched the video of Ryan Neal showing how to adjust thread tension. It compares the top and bobbin tension to a tug-of-war. That is a good analogy. I have been sewing thin nylon fabric with thick #346 thread top and bobbin. Lately my wife has bought lots of leather to make purses with. And, she wants me to sew them. Do any of you have some advice on how to adjust from the 346 thread down to 138 thread, and from thin fabric to thicker leather? I of course will change the needle type and change the feed dog and presser feet? Also, how to adjust the presser foot height? Thanks Dale

-

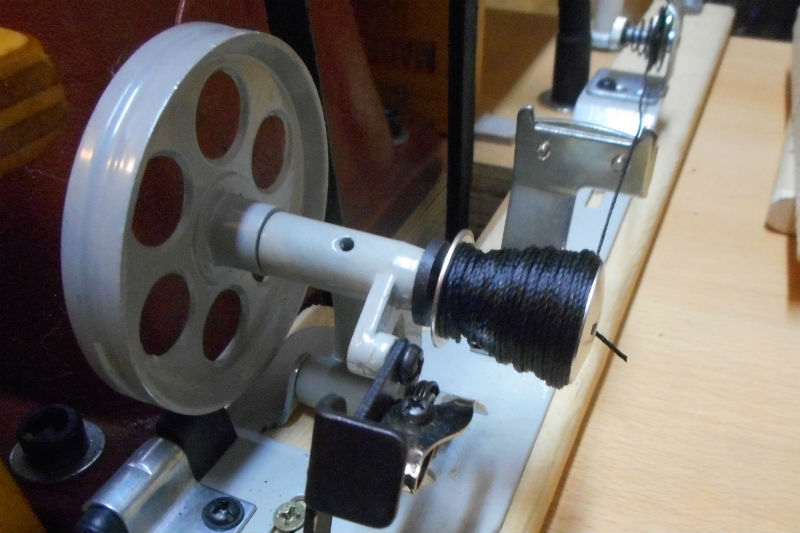

Hello, I have a small problem with the drive belt-driven bobbin winder on my 441 clone. This type of winder is on Cobra Class 3, Cowboy 3200, Nickosew 441-S, and other shorter arm 441 clones. Even though I have a Cobra Class 4 with its internal bobbin winder, Steve and David were nice enough to send me a Class 3 / belt-driven bobbin winder for free! Much praise to their customer service! Here is my small problem with it: After many adjustments of what I call the "slider bar", it refuses to put the thread evenly across the bobbin. It starts out good, but ends up with it on either one end or the other. This disengages the winder, putting less than a full load of thread on the bobbin. Does anyone have any tips as to how to adjust the slider bar to make the thread go on and end up evenly across the bobbin? Thank you Dale

-

hello art, thank you for your reply. again, i do not intend to market sewing machines. i am just curious. thank you. dale

-

just for curiosity, who in shanghai makes the cobra class 4 ? thank you dale

-

hello, thank you for your replies. in particular, i am looking for the factory of cobra, cowboy, artisan, and nickosew in that order of curiosity. again, this is just for curiosity, nothing else. thank you dale

-

hello y'all, i have a silly question. i promise not to start my own sewing machine company with the answer. i am quite happy with my 441 clone. i have been told by more than one seller of them that they are made in the same chinese factory. they just put a different paint job on them, and do slight changes that the seller orders. and, service after the sale is the largest difference between them. just for curiosity, WHAT IS THE NAME OF THE COMPANY THAT MAKES THEM AND WHAT CITY IN CHINA ARE THEY MADE IN? thanks dale

-

hello all, thank you for your replies. the support stand has been moved toward the machine about 2'. that eliminates the possibility of mid-sheet sag. it also makes room for a little folding table at the end. dale

-

hello y'all, almost a month ago i posted an idea for a work platform for a 441 clone machine. all the work platforms that come with the machines are way too small, so i made one that is 2' x 4' in size. and it worked great. now i have made one that is bigger and better than that one. it is 3' x 6' in size. it is held up into the proper place next to the machine by a pair of 6" long 2x4's that are 1.5" in from a cutout i made for the cylinder arm. see my previous post entitled "work platform idea" for the dimensions of the cutout. this platform is made of cabinet grade plywood, and finished with 4 coats of clear polyurethane. it stands on the other end on a stand made of 2x4's with one 1x6 for a shelf. if you have any questions, please ask. dale