jakc3

Members-

Posts

32 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Slovenia

-

Interests

Web development and leatherworking

LW Info

-

Leatherwork Specialty

None yet - still a beginner

-

Interested in learning about

Fine leatherworking, wallets, bags, briefcases

Recent Profile Visitors

2,104 profile views

jakc3's Achievements

Member (2/4)

-

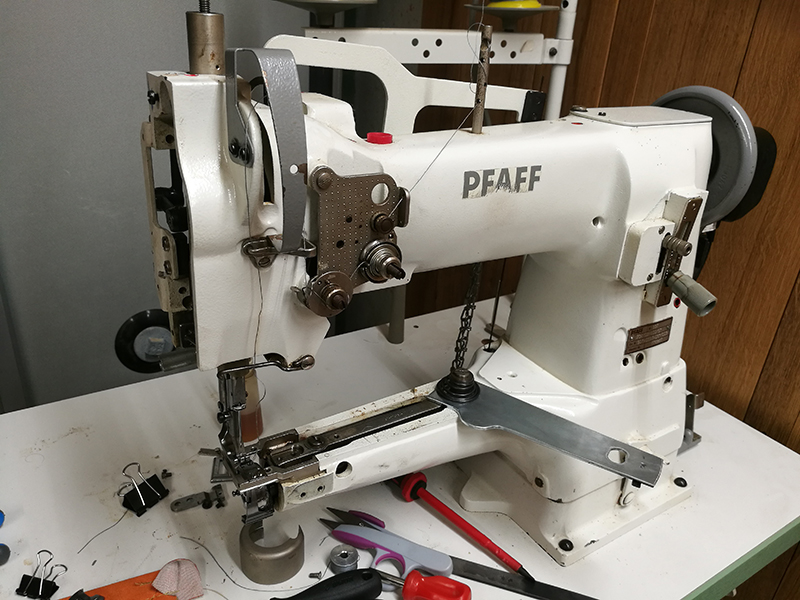

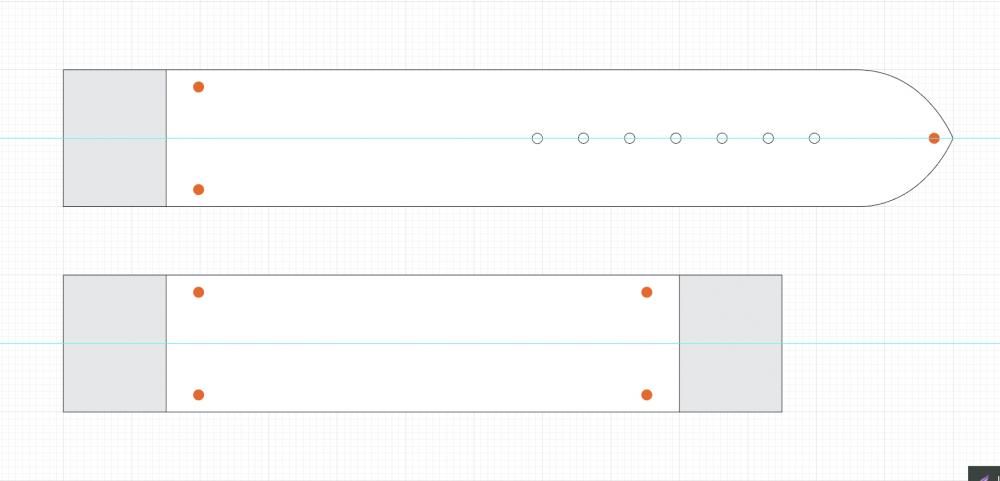

Heya, I come from hand sewing world and am just beginning to really learn how to use a sewing machine. Currently, I am trying to make a watch strap and am having difficulties lining up the stitching perfectly at 3 crucial points (start, tip, end). Starting stitch should be perfectly parallel to the ending stitch and the tip directly in the middle. How on bloody earth do you do this (see the image below)? I am trying to sew at somewhere around 10spi. Also, what is the best way to start and finish the stitch so it won't look messy and the thread will stay put/secure? Many thanks

-

As you noticed, the screw doesn't really affect the foot pressure. The markings appear only on the left side of the needle. A temporary fix I found is to sew the piece with baking paper underneath and then simply tear it away. It is extra work though and would be nice if the leather wouldn't get marked in the first place.

-

Hello, I have a question regarding feed dogs marking leather. I have a Pfaff 335 sewing machine with walking foot feed. On softer leather the feet marked it as well but I solved that by gluing thin leather on the bottom of the feet. I still have issues with the bottom feed dog marking the leather. It's smooth, without teeth and it moves only horizontally (maybe just a little bit vertically but it is a negligible amount - 0.05mm). What it does is it leaves a line, which can't be rubbed off, on the bottom side of the leather. First I thought this is because the plate covering it was slightly higher than the feed dog so I sanded it down to the same height. This however didn't solve the issue. Are there any solutions/workarounds to this? Many thanks, Jakob

-

I was unable to source this tool in my country so I improvise with fine sandpaper glued to a stick. I'll try to import it from somewhere and try it. It is weird because usually there were no issues with this even when I had to completely re grind the bevel. Besides that first question I have another. When I skive for example a fold over edge for a card slot the leather stretches and skews. What could be the reason for this? Perhaps transport wheel tension?

-

Hey guys, I've got a question regarding skiving machine sharpening. Usually this part didn't cause trouble until now. I simply can't get it sharp and the blade leaves these ridges which then also show on the surface if you bend the leather. How I'm sharpening: - First I move the blade into the required position (almost next to the foot) - After that I paint the bevel with a marker - Then I move the grinding wheel into position and grind until the bevel is nice and to the edge (the grinding wheel is almost new, so is the knife which I replaced not so long ago) Am I missing a step? This usually worked but for some reason it doesn't today. I did notice however that when i painted the bevel, if I sharpened it ''gently'' there were 3 depressions in the blade remained painted. Due to this I sharpened a bit harder and I think they flattened out. Here's a picture of leather I skived:

-

Thank you for the reply, this was indeed the issue.

-

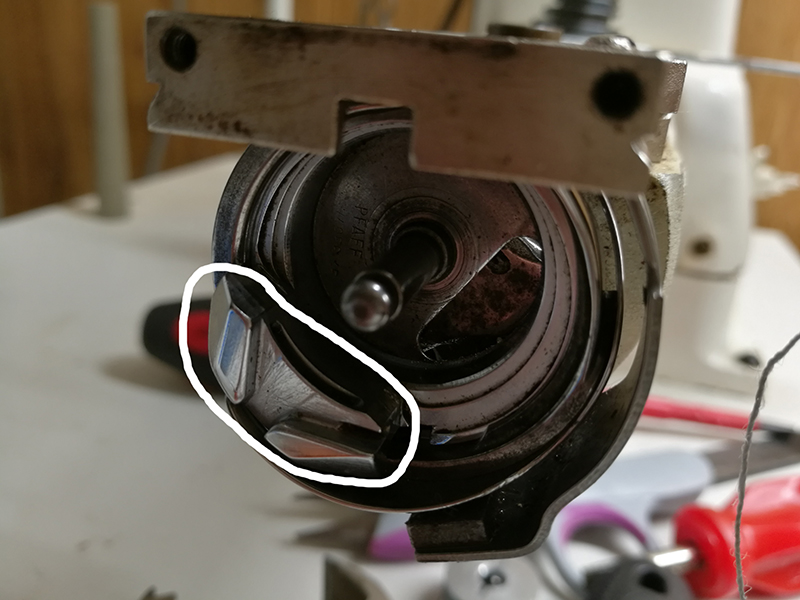

Hey guys I have some issues regarding my pfaff 335 (which I dont use much and don't know much about sewing machines in general). The main issue is that the needle hits the bobbin case and breaks. I timed the hook so the needle is 1.8mm up when the hook intersects the needle. The problem happens when the bobbin case is inserted and the inner part inside the hook part that spins freely isn't synchronized to the needle causing it to miss the hole and hit the bobbin case. Do you have any ideas what is causing this? Did I fail to time the needle/hook or is it something else? I attached a picture of my sewing machine and the hook/inner part thingy that is causing issues. Many thanks, Jakob

-

Thank you very much, it is indeed in mm without decimals.

-

Hello, I got in touch with a certain french tannery and they sent me the information about their articles. However I haven't yet seen such units for leather thickness or at least not with such numbers. Could someone please enlighten me on how these would convert to millimeters: 15/17 20/22 26/28 Many thanks, Jakob

-

Excellent, thank you for the information.

-

Hello, I'm interested in this kind of stitching and am wondering if somebody knows what's it called and how to make it. Also what are the benefits of using this stitch (better flexibility?). Another question i have is about a very small watch strap which a friend of mine ordered (less than 1cm in width). I made it out of three pieces since she wanted it to be raised in the middle (lining, core and upper part). How do I sew this since it's so small? I tried it on a test piece and the edges get distorted (wavy) the holes are very easy to rip. If i put the holes further from the edge it doesn't look so neat. Any advice? I'm stitching at 9 spi. Many thanks, Jakob

-

I just finished seting up the machine and it works perfectly. I got 3 new standard metal presser feet with the machine and I ordered the roller one too. Some pictures: https://drive.google.com/folderview?id=0B2IzdSTDuaz_dVkyR2VVRUZZb0k

-

Thanks, it's quite a pleasure to sew with it. Yes, the table looks almost too nice to cut hehe. Yes, I also have multiple bobbins that hold different threads. I will have it in couple of days, I bought a refurbished 50 PUAG Fortuna which I am going to pick up on Thursday in Vienna.

-

-

Thank you for the compliments. Yes, the exterior was hand stitched and parts of the interior as well. I will definitively give machine sewing the zipper a shot but i need to get some experience with machine sewing first. This bag's interior was the first thing I've ever sewn on a machine.

.jpg.8235aea71112aa02577505765079edd0.jpg)