jakc3

Members-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by jakc3

-

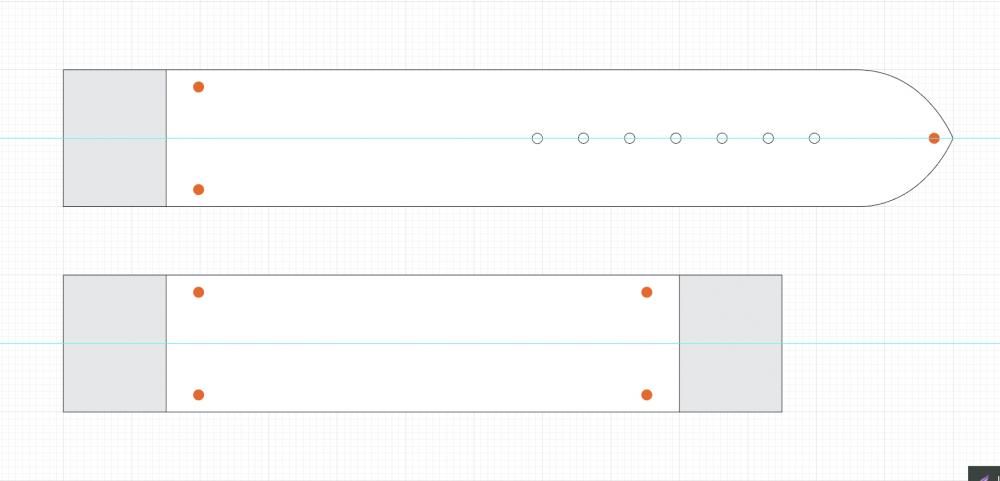

Heya, I come from hand sewing world and am just beginning to really learn how to use a sewing machine. Currently, I am trying to make a watch strap and am having difficulties lining up the stitching perfectly at 3 crucial points (start, tip, end). Starting stitch should be perfectly parallel to the ending stitch and the tip directly in the middle. How on bloody earth do you do this (see the image below)? I am trying to sew at somewhere around 10spi. Also, what is the best way to start and finish the stitch so it won't look messy and the thread will stay put/secure? Many thanks

-

As you noticed, the screw doesn't really affect the foot pressure. The markings appear only on the left side of the needle. A temporary fix I found is to sew the piece with baking paper underneath and then simply tear it away. It is extra work though and would be nice if the leather wouldn't get marked in the first place.

-

Hello, I have a question regarding feed dogs marking leather. I have a Pfaff 335 sewing machine with walking foot feed. On softer leather the feet marked it as well but I solved that by gluing thin leather on the bottom of the feet. I still have issues with the bottom feed dog marking the leather. It's smooth, without teeth and it moves only horizontally (maybe just a little bit vertically but it is a negligible amount - 0.05mm). What it does is it leaves a line, which can't be rubbed off, on the bottom side of the leather. First I thought this is because the plate covering it was slightly higher than the feed dog so I sanded it down to the same height. This however didn't solve the issue. Are there any solutions/workarounds to this? Many thanks, Jakob

-

I was unable to source this tool in my country so I improvise with fine sandpaper glued to a stick. I'll try to import it from somewhere and try it. It is weird because usually there were no issues with this even when I had to completely re grind the bevel. Besides that first question I have another. When I skive for example a fold over edge for a card slot the leather stretches and skews. What could be the reason for this? Perhaps transport wheel tension?

-

Hey guys, I've got a question regarding skiving machine sharpening. Usually this part didn't cause trouble until now. I simply can't get it sharp and the blade leaves these ridges which then also show on the surface if you bend the leather. How I'm sharpening: - First I move the blade into the required position (almost next to the foot) - After that I paint the bevel with a marker - Then I move the grinding wheel into position and grind until the bevel is nice and to the edge (the grinding wheel is almost new, so is the knife which I replaced not so long ago) Am I missing a step? This usually worked but for some reason it doesn't today. I did notice however that when i painted the bevel, if I sharpened it ''gently'' there were 3 depressions in the blade remained painted. Due to this I sharpened a bit harder and I think they flattened out. Here's a picture of leather I skived:

-

Thank you for the reply, this was indeed the issue.

-

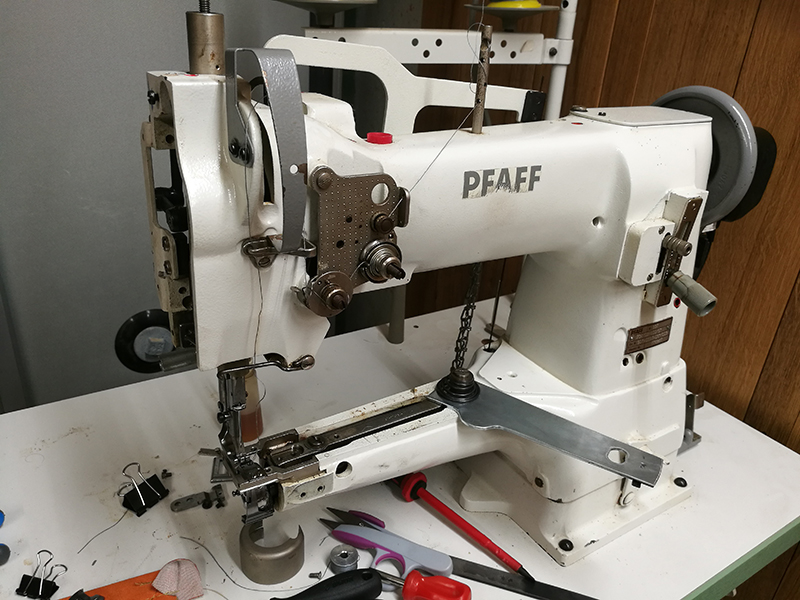

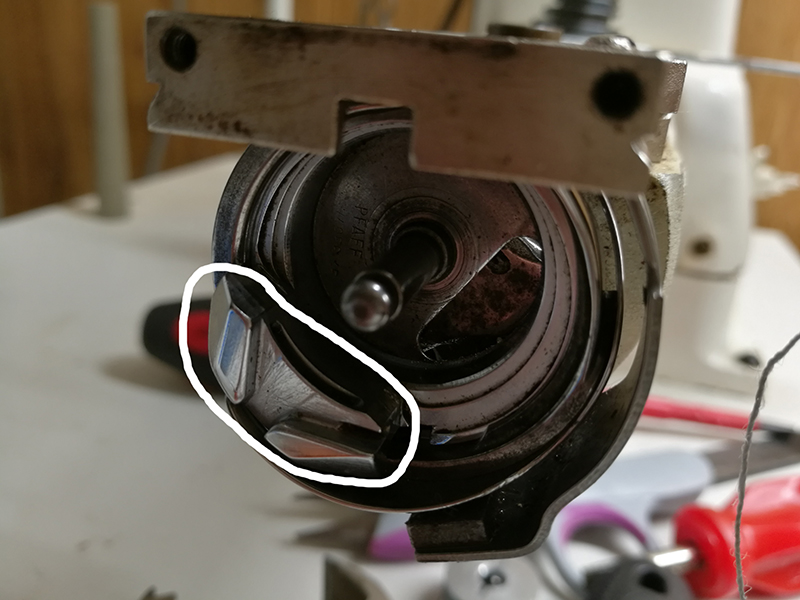

Hey guys I have some issues regarding my pfaff 335 (which I dont use much and don't know much about sewing machines in general). The main issue is that the needle hits the bobbin case and breaks. I timed the hook so the needle is 1.8mm up when the hook intersects the needle. The problem happens when the bobbin case is inserted and the inner part inside the hook part that spins freely isn't synchronized to the needle causing it to miss the hole and hit the bobbin case. Do you have any ideas what is causing this? Did I fail to time the needle/hook or is it something else? I attached a picture of my sewing machine and the hook/inner part thingy that is causing issues. Many thanks, Jakob

-

Thank you very much, it is indeed in mm without decimals.

-

Hello, I got in touch with a certain french tannery and they sent me the information about their articles. However I haven't yet seen such units for leather thickness or at least not with such numbers. Could someone please enlighten me on how these would convert to millimeters: 15/17 20/22 26/28 Many thanks, Jakob

-

Excellent, thank you for the information.

-

Hello, I'm interested in this kind of stitching and am wondering if somebody knows what's it called and how to make it. Also what are the benefits of using this stitch (better flexibility?). Another question i have is about a very small watch strap which a friend of mine ordered (less than 1cm in width). I made it out of three pieces since she wanted it to be raised in the middle (lining, core and upper part). How do I sew this since it's so small? I tried it on a test piece and the edges get distorted (wavy) the holes are very easy to rip. If i put the holes further from the edge it doesn't look so neat. Any advice? I'm stitching at 9 spi. Many thanks, Jakob

-

I just finished seting up the machine and it works perfectly. I got 3 new standard metal presser feet with the machine and I ordered the roller one too. Some pictures: https://drive.google.com/folderview?id=0B2IzdSTDuaz_dVkyR2VVRUZZb0k

-

Thanks, it's quite a pleasure to sew with it. Yes, the table looks almost too nice to cut hehe. Yes, I also have multiple bobbins that hold different threads. I will have it in couple of days, I bought a refurbished 50 PUAG Fortuna which I am going to pick up on Thursday in Vienna.

-

-

Thank you for the compliments. Yes, the exterior was hand stitched and parts of the interior as well. I will definitively give machine sewing the zipper a shot but i need to get some experience with machine sewing first. This bag's interior was the first thing I've ever sewn on a machine.

-

Hey there! I just finished my 2nd bag (1st one was a very simple turned messenger bag) which took me over a month to finish (in hobby time of course). Unfortunately I failed to anticipate how heavy the bag would be before deciding to go with all leather interior. It weighs around 4 pounds but that is mainly because the thinnest leather for the interior i could find was 1.1-1.2mm. The exterior is italian veg. tan leather and completely hand sewn but the interior is from chrome tanned leateher and is partially machine sown. It was also my first experience with machine sewing and adding zippers in general. Please feel free to write your opinion on the bag and point out possible improvements.

-

Thank you for your tips and photos, they have been of great help and sorry for a late reply (I was terribly busy, took me a month and a half to finish the bag). Here is the finished bag:

-

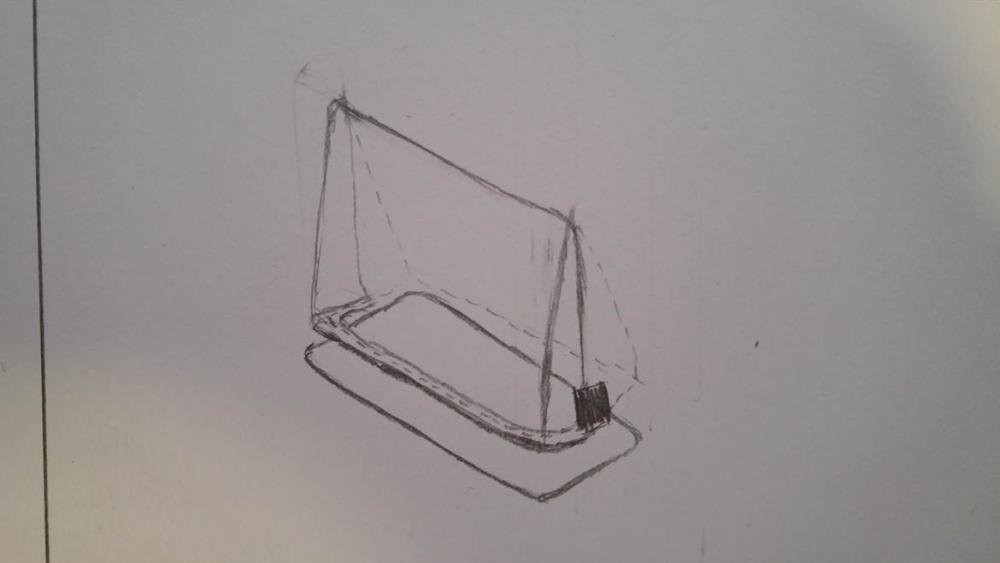

Hey fellas, I'd need some advice on how to sew in a lining/interior into this particular bag I'm currently making. The problem I'm having is that i chose not to sew the bag inside out but I went for visible edges on the bottom pannel. The bag has a long zipper that runs from side to side almost to the bottom (currently only taped on the pieces with double sided tape). The bag doesen't have a side panel but the front piece wraps around the corner of the bottom and meets up in the middle with the other piece. How should I go about sewing it up together with interior and all? I got a bit stuck as this is after all my first real bag (I've only made a simple turned unlined messenger bag) and I don't want to mess it up. Should i sew the interior with inner gussets and pockets together like a separate bag, insert it and then sew it along the zipper? Or line the pieces, sew on the bottom panel and then sew in the gussets + inner pocket? Here are some sketches and pictures of what i'm making: An exloded wireframe view of how i'm planning to put this piece together

-

Thank you all for your constructive critiques. Yes the wallet is lined and I'm planning to sew the next one all the way to the other side, that will most certainly help with durability. The card slots do indeed have a pocket underneath and for that there is a thin leather panel to serve as a base for the card slots. Does anyone perhaps know how to keep the stitches angled when sewing thicker leather (like the edge of the wallet or edges of briefcases,bags etc.)? WIth my current technique they get kinda straightened out and I'd like them to be angled. I'll be recieving a delivery of blanchard pricking irons sometime next week and I hope that will help with that.

- 8 replies

-

- leather

- wallet bi-fold

-

(and 2 more)

Tagged with:

-

Heya, Here are the first two bifold wallets I ever made and I would love to get some feedback on what things I should improve. On the two-tone wallet I used braided nylon thread and on the light brown one i was trying out the fil au chinois thread i just recieved. It is like learning to sew leather all over again. The leather is tumbled veg tan full grain italian leather. Images: More images: https://imgur.com/a/ytfBx

- 8 replies

-

- leather

- wallet bi-fold

-

(and 2 more)

Tagged with:

-

Hello, Could someone please enlighten me about a few types of leather. I got in contact with an Italian tannery and I'm going to go visit their tannery and buy some leather from them in a couple of weeks (they aren't so far from where I live). They specialize in vegetable tanned leather (the tannery is a member of this consortium) and they offer double shoulders in different finishes. Natural finish Double oiled natural finish Dyed through, aniline finished, smooth, matt Dyed through, aniline finished, smooth, bright Dyed through, aniline finished, tumbled/ drummed, matt Dyed through, wax, tumbled/ drummed, bright Dyed through, no finish, tumbled/ drummed What does analine finished mean? Can you finish the edges of analine finished leather in the same way as you can with natural veg tan leather (burnishing)? They say that their leather is selected for belts. Does this mean it has fewer marks (handbag grade) or more, like an accesory grade leather? Also what type of leather (listed above) would you recommend for making travel bags and handbags? I can afford to buy thicker leather and then split it for smaller items such as wallets as I will be buying a splitter in a couple of weeks. Many thanks, Jakob

-

I am from Slovenia. We had a few very good tanneries and lots of good companies producing leather products, most of which went bankrupt at the end of the previous century due to the bad economy, poor leadership and corrupted government. Because of this there are many machines in the hands of people who worked in those companies and got the machinery as compensation when the company closed down. Nowdays the leatherworking is almost dead here and I think that's why the price is so low.

-

Well I went and saw the machines personally. The splitter looks in mint condition and it works perfectly well too. The sewing machines look like they have been through a lot but they work well. Anyhow at 100 eur per sewing machine I can afford to have it serviced if anything is wrong. Also the man offered to teach me how to use the machines before selling them. He looks trustworthy so I will most likely go through with the deal.

-

Hello! I need some help with a deal. Someone i know put me in contact with an older leatherworker who is going to retire in a couple of months and he is selling his machinery. I went to see what he's offering today and he made me a great offer. All the machines are older models but they were well taken care of. He is selling: German Fortuna leathet splitter (35cm width) German Fortuna edge skiver 3 Pfaff sewing machines (each is different but i do not know the models) All of the machinery is industrial grade ,built like a tank, he got it from factories that went bankrupt in the '80s and '90s. He is offering me all of the above with lots of spare parts and other small things like thread, needles, stitching pony, rivets, some handtools etc.. The price is 2500 eur which is somewhere around 2800 dollars. Is this a good deal? He will also put me in contact with people who know how to service these machines and with people that sell spare parts. Many thanks, Jakob

.jpg.8235aea71112aa02577505765079edd0.jpg)