-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TheHollerLW

-

Great job

-

Weaver Easy Edger Marking Bottom Side of Leather

TheHollerLW replied to PheesOriginal's topic in Leather Machinery

Its not much of a modification, there is a small sharp edge/ bur on top of the lever. A quick polish is my game plan. I reached out to them for there recommendation before I do it.- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

Weaver Easy Edger Marking Bottom Side of Leather

TheHollerLW replied to PheesOriginal's topic in Leather Machinery

Myself- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

Weaver Easy Edger Marking Bottom Side of Leather

TheHollerLW replied to PheesOriginal's topic in Leather Machinery

modifying the tension levers that are making the mark on the leather- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

Weaver Easy Edger Marking Bottom Side of Leather

TheHollerLW replied to PheesOriginal's topic in Leather Machinery

Weaver told me its normal and said to adjust them down a bit and try to stretch out the tension springs. I tired that and got the same result.- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

Weaver Easy Edger Marking Bottom Side of Leather

TheHollerLW replied to PheesOriginal's topic in Leather Machinery

I just got mine last week and Im having the same issue. I contacted weaver and did the adjustments they suggested but I have the same result.- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

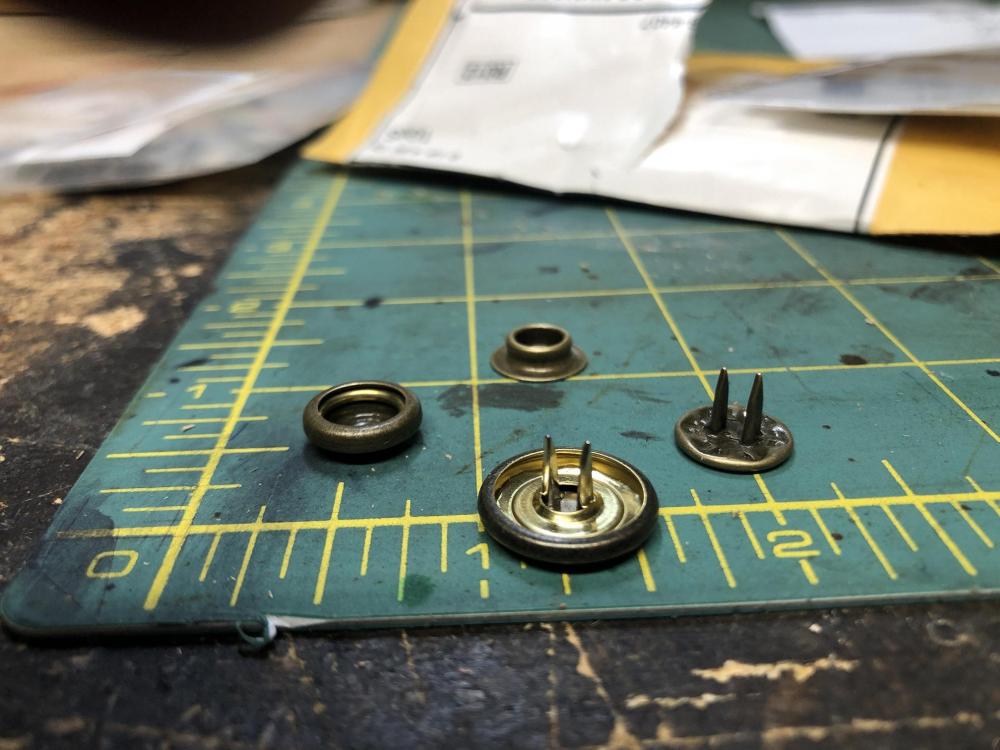

Does anyone know about these snaps

TheHollerLW replied to TheHollerLW's topic in Leatherwork Conversation

Thats what im thinking, I reached out to Filson -

I have a customer that just hooked up with Filson. So they sent me Filson's snaps. I have never seen this style before. I guess what i would be looking for is dies for my press, but I dont even see how you would had set these nor can I find hand setters for them. Thanks

-

Noticed tonight some bit of smoke after sewing for 30 min, I changed needle and still same result. I cant seem to find any other parts with heat in bobbin area, just needle. I re threaded as well. Also let it cool and just ran about 50 stitches and it was hot. Thanks

-

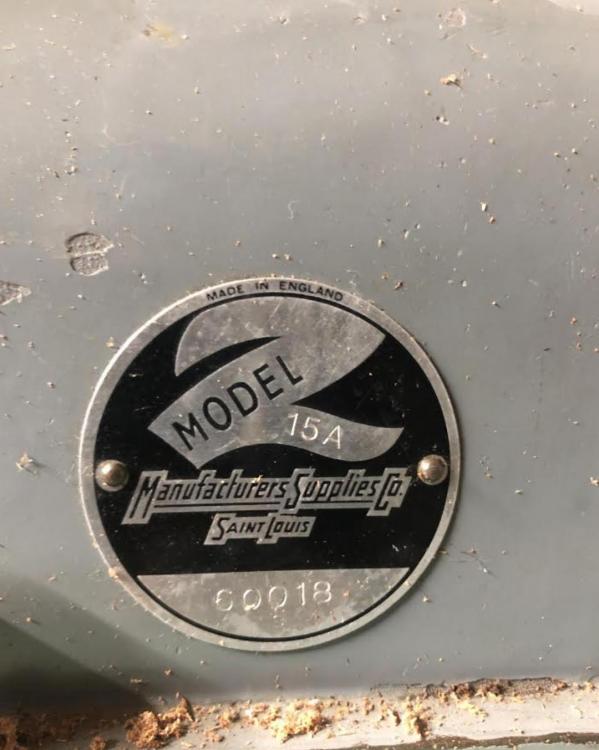

Manufacturers Supply Co 15A I can't seem to find the correct belt for my machine, and the parts list i have doesn't list the roller feed belt. Any help appreciated Thanks

-

Last night I was sewing fast and when I went in to reverse I snapped a needle. After replacing needle I now can now not get shuttle to pull up bobbin thread. The Shuttle hook is not grabbing mt top thread. I assume my timing is off but the videos and support of Solar leather are no long available. I can post move photos or videos if needed. Thank you

-

Thank you

-

I hope this is the proper place to post this I recently just purchased this machine and after a few days i was able to figure it out, i am new to serger machines. I got it working pretty nicely. Sometimes it stitches perfectly but more often that not the needle thread stops sewing. Any help is much appreciated. Thanks

-

I posted this in the For sale section but got to attention Does anyone have a table they would like to sell that they dont use?? Thanks!

-

Thank you very much

-

Not always but when i go from two layers of leather to a single layer the thread pattern just gets destroyed. In this case its two 3.5 oz pieces of leather and im using 138 on a coyboy 3200 thanks

-

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

-

Anyone have one to get rid of?

-

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

Could you post a photo of your modification? -

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

Was from a dealer, Solar leather. Spoke to them they are sending another foot but the one I have is very smooth I think it’s something else going on. My buddy had a 3200 and it does not leave a round spot ever needle punch -

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

Yeah I’m not giving up on this machine haha I love it, the photo is two 9oz pieces. But I have tired it on many thickness with same result. I will look online to lower the fees dog, is there a foot that is different? That isnt a round hole? -

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

-

Pressure foot issues with Cowboy 3200

TheHollerLW replied to TheHollerLW's topic in Leather Sewing Machines

I’m using 207 with 200/25 needle here is a pic I’m not sure what the feed dog is on this machine. I’m new to machines -

I am new to this machine, I have notice a circle around ever needle hole. I realize veg tan is going to have plenty of marks etc. I have the pressure foot adjustment as light as it will go. I too the foot off and it is very smooth but a took a high grit sand paper and then buffed it and i still ave some results. Anyone have any advice? Thanks

-

oh ok i get it, thanks Bob

.thumb.jpg.8c2385f6bad1ff0b6ed4898735a05bde.jpg)