-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by HardenGoods

-

Adler 067 GK-373 tension problem (advanced)

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

This problem appeared on many different kinds of leather but I can definitely see a particular tannery or batch playing hard to sew. I’m in the middle of figuring this one out I think. I’ve noticed my takeup lever ascending before the thread reaches the 3:00 position around the hook which creates some random/inconsistent resistance, in turn, altering tension randomly. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

That would make more sense for sure. I’ve seen several machines with their bevel gears either covered in or encased in grease. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Wow. I'm not surprised after seeing your setup... new... old/dead stock seems like the best it gets. Treasures waiting to be unleashed haha. Agreed. That Adler 67 taught me how many things have to work with and off of each other in just the right way/time to accomplish what the machine was set out to do. Also, I hope this isn't too late for this (2600) machine because I sent the video to the tech and he said it was normal. Doesn't seem normal. Looks great. Something about a well fitting stamped pan does it for me a little more than what looks like scissor cut felt . Did you have many of the same clones to choose from when buying the Honbo? Lately, I often wonder how one knows which copy to get when they all tend to look the same. Reputation goes a long way but it seems to be difficult to acquire useful info on which manufacturer produces said machine best. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

I will check the play and movement a little later when I am back in front of the machine. Yea, I really like the pan idea! -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

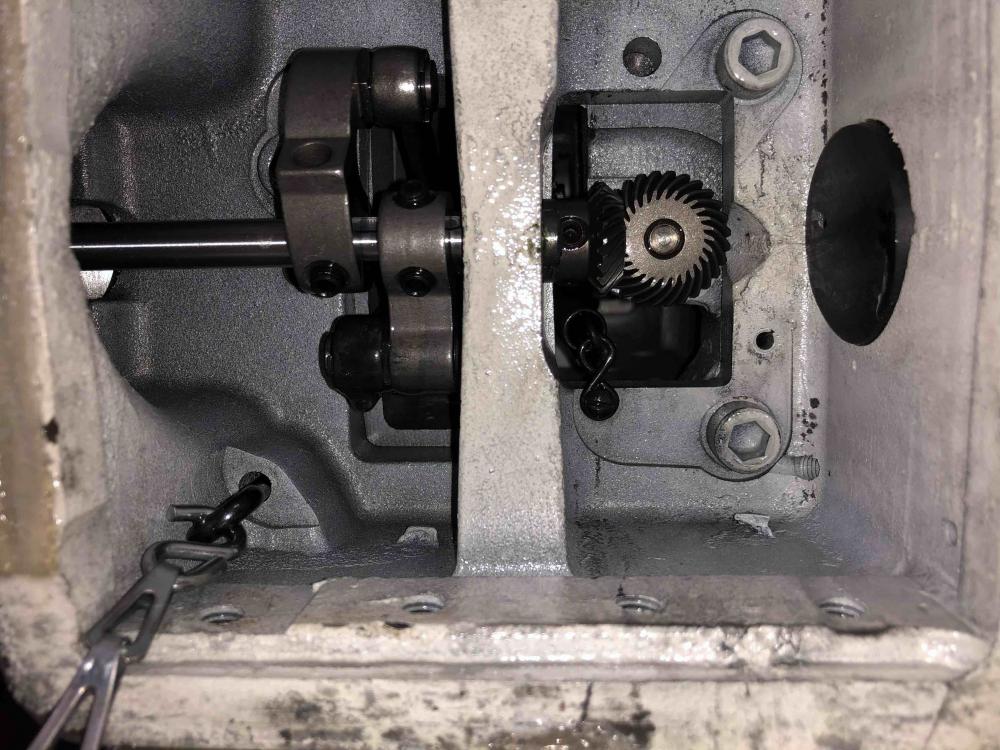

I hope it doesn’t need them. The oil pan is taken from a video from “Alden’s School of Leather” on a Juki 341 copy. Not my oil pan but made me think my machine should or could have one. No rubbing in the hook area. All is well on that end after careful inspection. The noise comes from right near the gears in the photos. Thanks for the help kgg. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Thanks for the insight Floyd! I appreciate your thoughts. The noise definitely seems to be coming from in and around the lower driveshaft gears though. Kgg, I suspected something similar because of the particular sound of the grinding noise. After tilting the head of the machine back I do notice some discolouration on the oil pad but this may also be normal for break in (although I'm positive the noise is not). I was also surprised to not see an oil pan under here which I've seen on some other Juki clones, but maybe not necessary. Also, the rubber gasket came like that. I continue to place it back where it should be but it is too small for its purpose. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Cheese grade haha.. I concur with you and your tech on that. You are absolutely right about the pros of the machine. The narrow cylinder arm is great and the bobbin size is a game changer for anyone coming from smaller sized bobbins. My reverse works well too. That was the first thing I tried. As I’ve had lumpy belts before too. Belt looked fine, tried a new standard belt and tried a link belt with no real change in result. Thanks for this pointer though, I can see that fix helping others. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Vibrates and grinds with other motors still, just a little less. Hope your end result with the motor is good, Plinker! I’m with you 100% on that. I’m glad you ended up with a solid machine! -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Looking at a copy of both the Juki 1508 and the Juki 341. Both branded "Kobe". I ordered a Techsew 2600 a few weeks back and am not happy with it at all. My initial impressions were that it all looked pretty nice but upon closer inspection and use, my experience started to change. The machine vibrates an unreasonable amount and I was told it was normal due to torque increase which sounds reasonable, although, I’ve got 5 servos in my shop and none of my machines shake rumble and grind like the Techsew. The thread stand shakes a remarkable amount (and it is fastened properly) and it sounds like gears are grinding inside the machine. Castings are super rough and the underside of the table (legs) feels flimsy. Here is a short video of the machine without a load. It does this to varying degrees with different materials. Techsew has a really strong following and have been super nice guys to deal with when they do get back to me but for just under $3000, the machine just feels so cheap to me to be honest. This definitely won’t help me sell the machine (which was timed and sews properly!) but it is true. Will keep it up in the classifieds until someone purchases it, as it does sew well and comes with a really beautiful table attachment from Uwe. Excited to see what Chris has in store though! -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Glad to hear that. I got a really solid vibe off the guy too. Going to see him next week. -

Juki 1341 experience? pros cons?

HardenGoods replied to plinkercases's topic in Leather Sewing Machines

Did you end up with this machine? Curious to know if you like it. -

Adler 67 Timing Belt Placement

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

That makes a lot of sense Bob. I had wondered about that too because I’ve adjusted the feed dog on this particular machine several times from underneath. The main reason I asked the question in the first place was because I’m trying to see if it is possible to advance the takeup lever to hook timing because my thread is very tight when passing around the hook and seems like it is due to the takeup lever being early (as I’m pretty sure the take up lever shouldn’t start it’s ascent until the thread is at the 3:00 position around the bobbin case). -

Adler 67 Timing Belt Placement

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

Thanks for this info! -

No. The 2600 is a copy of the Juki 246. Comparing the 2600 to the CB4500 is strange - mechanically, they are very different. Perhaps you should do some more research before you start asking questions that can easily be obtained via the search feature and questioning if my machine is a “chinese knock off”.

-

Thanks for bringing this to my attention. This is in Canadian dollars and is available for pickup only - will change post now.

-

Brand new Techsew 2600 walking foot sewing machine. Purchased a few weeks ago and has only sewed samples. Machine has been timed, tuned and inspected by Techsew and is ready to sew. Comes with a really beautiful tabletop attachment made by Uwe. The machine can be used as a standard flatbed or can quickly be switched over to cylinder arm setup. Comes with the following: Machine head and table Custom table attachment Premium Techsew motor with optional needle position adapter (sold separately) Swing down roller edge guide Double toe presser foot Left toe presser foot Manual Inspection certificate Magnetic led sewing light Needles Tool kit $2850 CAD. Local Pickup only, located in London Ontario Canada. Any questions, please feel free to pm me.

-

Anyone know if the Adler 67 (subclass GK373) has factory notches on or near the main shafts and gears for point of reference when replacing the timing belt? I’ve seen several machines with markings on the underside so as to know when the shaft and gear are in the correct position, I just don’t see them on this particular Adler head. I’ve read the service manual but don’t see any mention of the timing belt (other than part identification). Any help is super appreciated.

-

Adler 167 - Timing Belt Replacement

HardenGoods replied to Constabulary's topic in Leather Sewing Machines

No worries. I have the service manual but couldn't find anything. Will take a closer look. -

Adler 167 - Timing Belt Replacement

HardenGoods replied to Constabulary's topic in Leather Sewing Machines

When you got the new belt on did you have factory reference points on the machine's top and bottom timing belt gears (or somewhere else) to keep shafts synced? Looking over my Adler 067-GK373, I'm not seeing any factory markings. -

Needle bar hitting outside foot on Adler 67

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

Needle being longer would lift the needle bar higher and out of the way after adjusting - that makes perfect sense Gregg! New needles and I'm pretty sure this case is closed. Thanks for the insight, I appreciate it! -

Needle bar hitting outside foot on Adler 67

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

My apologies for the double post. I meant to attach this but don't see an edit button and am new to the site. Needles that came with the machine: -

Needle bar hitting outside foot on Adler 67

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

I used your paper clamp idea (from the 67 timing video) to hold the bar hieght in place while I rotated it slightly. You were right Uwe. I purchased this machine in very poor condition. The previous owner was using singer bobbins in it and 134 needles, vs 134-135 (which I'm now assuming are a little longer). I'm somewhat new to industrial sewing machines but have been reading/watching everything I can. My previous problem I had posted about was in regards to extremely random top knots. A little research and I find out the bobbins that came with (and inside) the machine are several mm wider than the proper bobbin: part number 068-180-0. My biggest mistake was assuming the accessories and original setup of the machine was correct. Learning some really critical things here.. actually, your Juki LU-563 video taught me a lot of important pieces of information too. Luckily I purchased my 441 clone and accessories new so not as many learning curves there (and looking forward to modifying my blanket feet into in-line too). -

Needle bar hitting outside foot on Adler 67

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

Thank you Uwe, I was worried that moving the needle bar over more, even slightly, would interfere with my machine's sewing abilities (although it seems a long shot as it would be something like 1/32" of a turn). Going to double check all systems and will report back. Thanks for your input! -

Needle bar hitting outside foot on Adler 67

HardenGoods replied to HardenGoods's topic in Leather Sewing Machines

That was the first thing I tried after re checking timing. Unfortunately, still touches. Below. I've tried several thicknesses of leather and (obviously) the thinner the material the less chance of contact. Yes, I agree that this is good practice. -

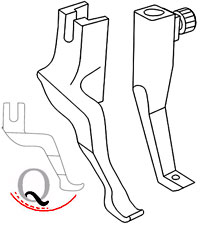

Hey guys, thought I'd touch base with the community before I started modifying. I recently purchased several sets of presser feet for my Adler 67 GK 373. One of the sets was a Kwok Hing KP267Q (as pictured below). When the needle bar makes its decent down towards the hook, the thread guide on the needle bar touches the outside presser foot with enough force to do damage. Was wondering If there was an adjustment I could make to my machine but I'm assuming no as the needle bar is set to meet the hook at perfect timing already. Because these specialised feet protrude forward (as they are intended to) I am wondering if slight foot modification is necessary. Machine has been timed and serviced and sews beautifully with all other foot sets. Any advice would be appreciated - thank you in advance.