EMI

Members-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Athens, Greece

-

Interests

Sewing machines, leather & canvaswork, woodworking, watch repair, fountain pens, vintage machinery, boating.

Recent Profile Visitors

3,289 profile views

EMI's Achievements

Member (2/4)

-

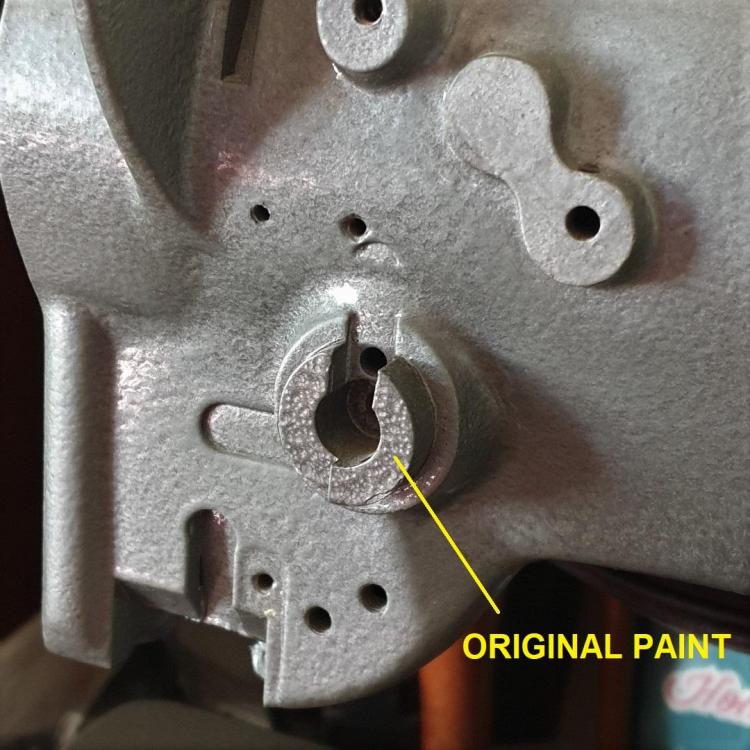

You may buy a couple of different colors ( e.g a silver & a darker grey) and mix them to get the right shade. You will need a spray gun to apply it. The difficult part is to match the original factory hammered effect. Each paint ends up with different hammered effect depending on the maker, application method, paint dillution etc. For local touch-ups I've had better results by applying it with a paint brush or sponge in a dabbing fashion. Its still hard to get a 100% match though In the attached photos example of repaint job on a 226R i am working on. You may notice the difference from the original in the close up of thread tension controller mounting hole.

-

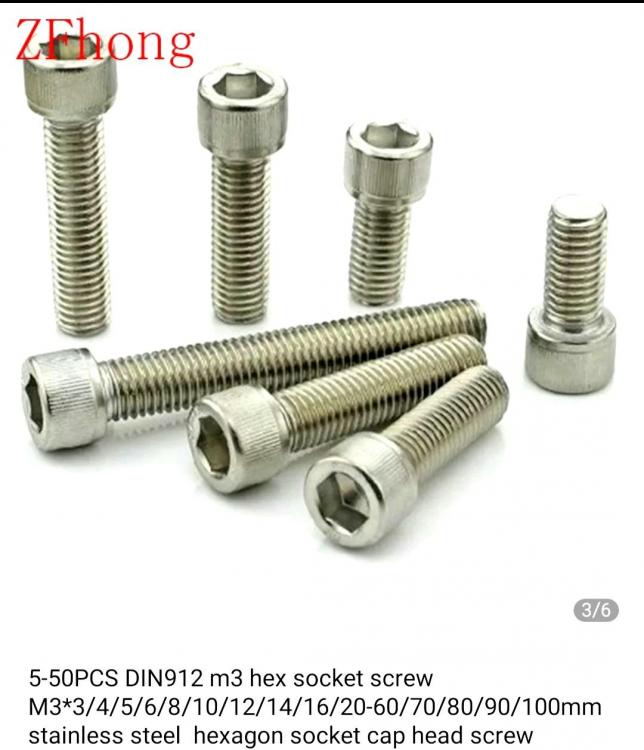

Right. I've also got them from Aliexpress for around $2 a bag of 50 pcs. Even the locally available ones are made in china.

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

Details of the M3 types of screws I found compatible with my machine (I had to file a bit the heads as they were a bit larger in diameter than the holder's recessed hole).

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

It's a lovely machine and the twin needle holder gives you more configuration options than the single one. It doesn't worth the trouble to have it replaced for the sake of a couple worn screws ( especially since there is no guarantee that a second hand replacement part wouldn't have worn screws too). My advice is to measure with a caliper the external diameter and the length of your screws and get new matching ones. I've also replaced mine the same way. They were metric with M3 thread and tried different types (with hex socket and torx heads)

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

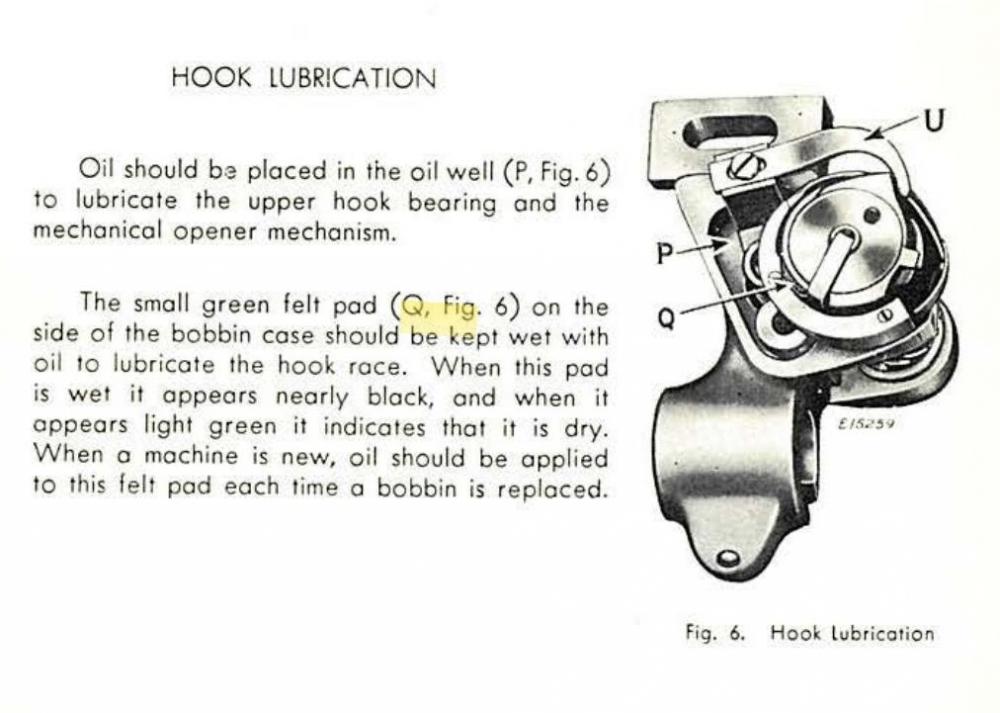

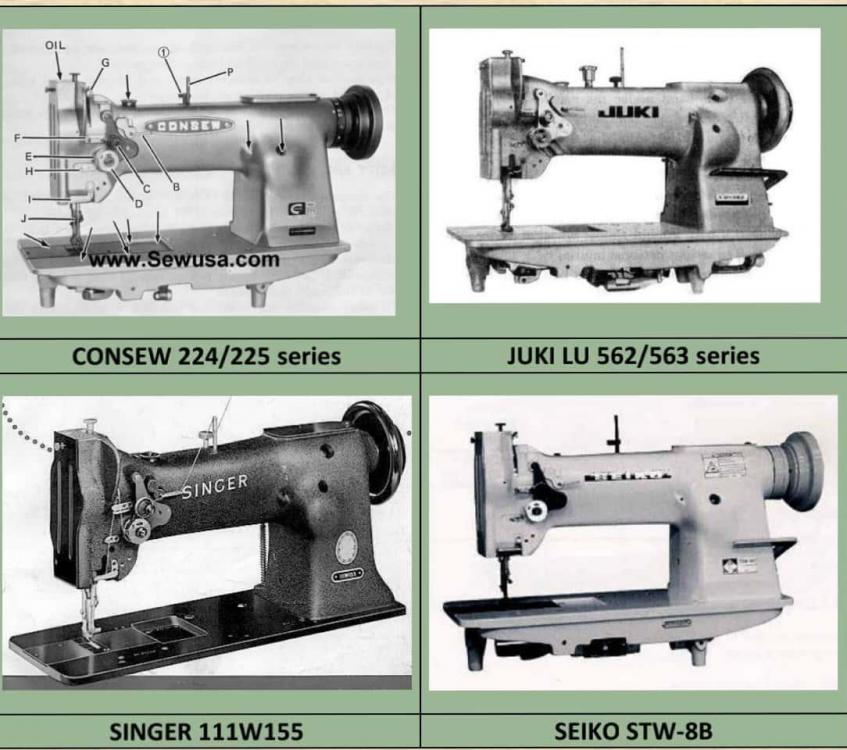

For the sake of clarification and without any intention to debate other opinions, please let me just say that my approach in such cases is, if it is there it belongs there for a reason, and in a proper maintenance or restoration work if it is missing it needs to be replaced (especially when it is so easy to be done). Singer’s manual is self explanatory in this respect. However, it is true that this felt has been omitted in later versions of Singer machines and is missing entirely from clone machines (Consew 225, Juki, Seiko etc) and its function can be substituted by regular manual oiling. I don’t know if it was done because they considered it un-necessary or as cost saving measure (steel parts have been also substituted by plastics in newer machines as allegedly superior maintenance and grease free components). The choice of replacing it or not is of course yours. I still believe though that a felt reservoir does provide a more uniform film of oil in such a high-speed rotating critical component and prevents the risk of either running it dry or splashing oil to the needle plate by overoiling it.

-

Yes it is essential for proper lubrication. However, in lieu of the original you can easily make it yourself from wool felt material.

-

Thanks for the info. Lack of reverse is not such a big issue. However the "A" class designation (as opposed to BL ones I've seen in photos on the net) is what puzzles me.

-

I am looking at a Pfaff 34 on sale for 100 euros (body only without motor/table). The sub class appears to be 34 -705/03-AL with roller presser and most probably wheel feed. The machine is advertised as leather working ( shoe uppers and medium weight leather ?) but except from parts list ( ref link below) I didn't manage to find any concrete info on the net or in this site regarding her stitch length, needle system and needle/ thread sizes. https://www.google.com/url?sa=t&source=web&rct=j&url=https://www.supsew.com/download/Pfaff/Pfaff%2034.pdf&ved=2ahUKEwiFub2vx_zsAhVH9aQKHdD3CasQFjABegQIAhAB&usg=AOvVaw2K_dytlfXdvb4zCPRLTaAu Furthermore the code letters AL are also a bit confusing to me (A= Light materials & L= leather). Does anyone has experience or info on this particular model ? Would you consider it as as a worthy purchase in a supplementary role to a Consew 226 for medium leather and synthetics/faux leather work ? I understand that spare parts may not be widely available ( if needed).

-

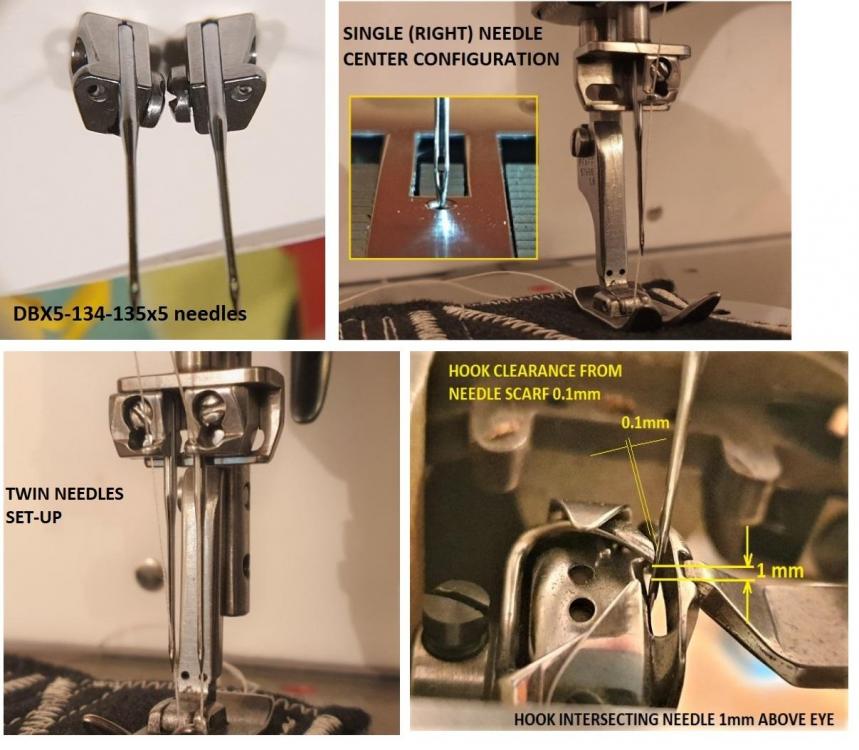

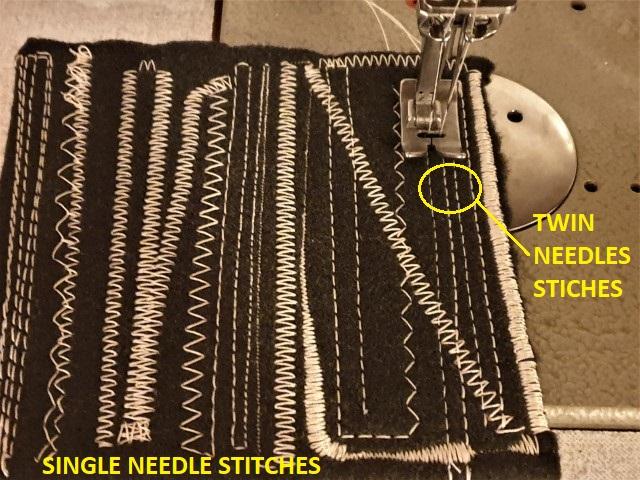

After my unsuccessful attempt to fit DBx1/1738/16x257/287WH needles I’ve tried once more the DBX5-134 needles. Their 2mm nominal diameter shank (actual measured diam. of Schmetz needle 1.94mm) is a very tight fit in holder’s holes, impossible to be inserted by hand and feasible only with a pair of pliers, but it worked. I centered the right needle for single needle sewing. Twin needles may be set up to 6mm apart (i.e. machine’s zig-zag width range). Upon fine tuning of hook timing tests in both single and twin needle modes were done with satisfactory results.

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

Just brought 111g155 at £90 inc table and clutch motor

EMI replied to chrisash's topic in Leather Sewing Machines

Is it a service or user manual ? I may need all the help I can get with the reassembly and final tuning of my Consew 225R and the US army/navy service manuals are a bit hard to follow. -

Just brought 111g155 at £90 inc table and clutch motor

EMI replied to chrisash's topic in Leather Sewing Machines

Congrats, really nice find. For a sister Consew 225R machine I am currently overhauling I found the US Navy Course NAVEDRA 14217 manual very helpful (Link below) https://www.google.com/url?sa=t&source=web&rct=j&url=http://keysew.com/Webpages/DemoImages/USNavySinger111WConsew225REPAIR.pdf&ved=2ahUKEwjR0bGA0O3sAhXKyIUKHaxQBzMQFjAAegQIARAB&usg=AOvVaw2W219vX6s2_tJX2L_mg6u7 Consew 225, Juki LU562 and Seiko STW8B clones are very similar.The Juki and Seiko parts list manuals helped also alot (very clear illustrations) -

Update on the saga of PFAFF's double needle holder needle system. I've tried a few Groz Beckert DBx1/1738/16x257/287WH and DLx1 (same basic dimensions but with shorter shank) needles but none of them found possible to be clamped in the needle holder. It turned out that their shank diameter (measured at 1.55mm) is too small for the clamping range of this holder.

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

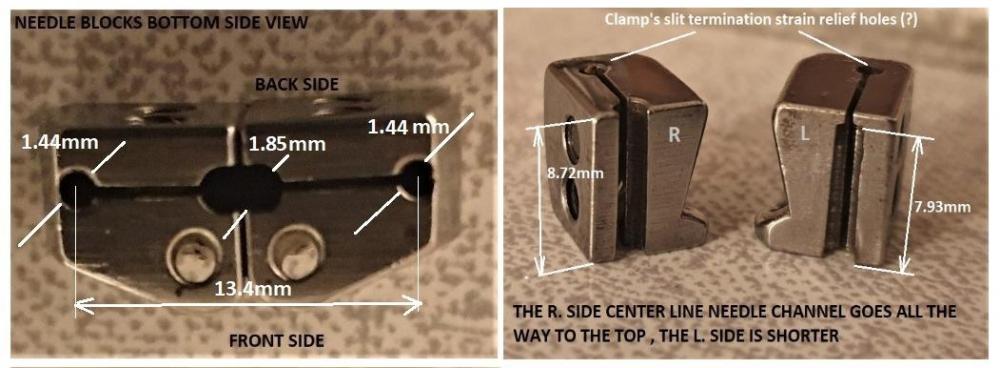

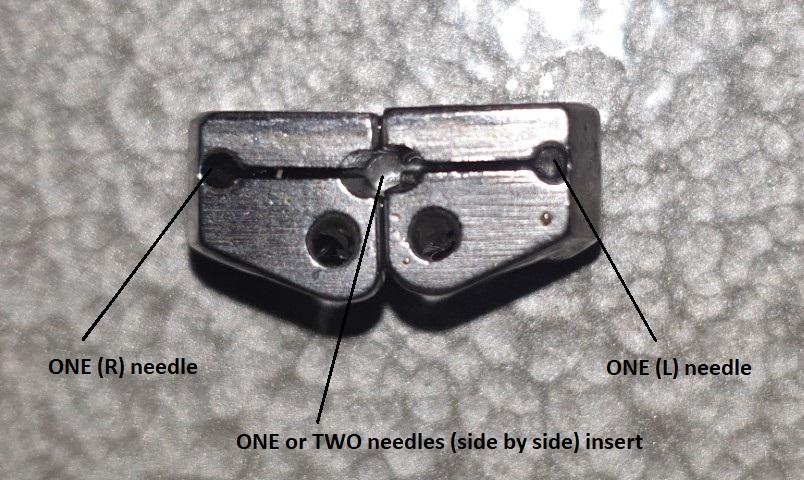

After a more careful re-measurement of the needle holder holes I believe that my previous assessment is wrong, so please disregard my last post above. The two outer holes are 13.5mm apart (a rather big distance for a single bobbin twin needle configuration) and of 1,44mm diameter (too small for any needle shank), so I tend to believe that they are just clamp’s slit termination strain relief holes and not needle sockets. It appears to me that the only needle sockets are the two middle holes, approx. 1.85mm in diameter and of 7.93mm (L) and 8.72mm(R) length.

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

I’ve checked the manual of PFAFF 130-115 (predecessor of the 138) to find any possible info related to PFAFF’s twin needle holder configuration. As it turned out, the 138-6 twin needle holder seems to be a variation of the 130-115 one with essentially the same features. It is meant to be used as a single, double or triple needles holder with (most probably) 130B system needles. Extracted pages of 130-115 manual hereby attached for easy reference. It appears that round shank 130B needles are used in the outer holes. A single 130B needle or two 130B needles may be inserted in the middle clamp jaws grooves. For very fine cording two special type left and right needles 130BL and 130BR with flattened shank (like the domestic needles) are inserted in the middle clamp jaws grooves as a single needle with the flat surfaces facing each other. I still didn’t manage to find out the purpose of the L & R middle grooves length difference though. My biggest concern now is if the machine could be used with its current needle bar/holder and probably matching DPx1/1738/287 needles for my intended purposes (medium weight fabric & canvas/upholstery works with needles sizes up to 110/18-120/19) or shall I consider modifications to a regular 138-6 needle bar/holder ( assuming availability of necessary replacement parts).

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with: