-

Posts

14 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.AbrahamArtist.com

Profile Information

-

Location

TX

-

Interests

Painting, metal, computer, leather, etc.

LW Info

-

Leatherwork Specialty

Very little to none.

-

Interested in learning about

Leather craft

-

How did you find leatherworker.net?

Pinterest post

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

abrahamd2k's Achievements

Member (2/4)

-

Free spill stand for Fiebings 440ml dye

abrahamd2k replied to chrisash's topic in 3D Printers and Lasers

Need to make one soon. Already had a spill last month. Thank you for sharing. -

It seemed it was CNK just like it reads. I was surprised that quite a bit of major Russian knife makers had their brand logos and writings on knives in plain English. But I understand what you mean.

-

I did a search on a Russian Image search engine https://yandex.com and this knife which is nicer than mine came up. Notice the similar style image below. Called American Tanto. Another site selling one called it a "Boot knife" made in China under the brand 'SIBRTEH ' Another site source called it a Universal Knife. Also used for leather and fishing and many other materials. Guess the one i got was a cheap knockoff of these brands. lol. Popular knife style for utility use in the East I guess. Now I need to learn what the steels carbon reading is on the knife in Russian standards mean. This one says 3Cr13x and that symbol at the end. My knife would have read "HIgh-quality steel 9x (w symbol)" Well had fun. Thank for the help and advise guys. I'm going to make a couple in this similar style out of some old files and a comfortable wooden handle to beat. I will post some pics when I am done.

-

LOL yup this knife has many job titles in the past and putty knife is one of them too.

-

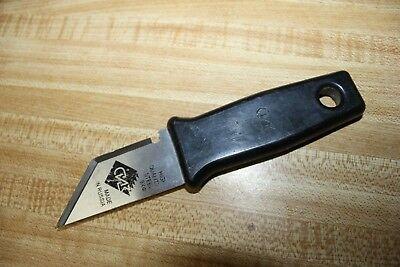

This is an image I found on Ebay, this one was sold at 30 to 40$ and posted as rare. Now I know the maker (CNK) but can not find anything about them online. Still uncertain of what it was for. Had a plastic handle that broke one time and I fixed it. Think I will make two of them out of old files one day with opposite cutting sides.

-

I dont see how that could turn a screwdriver.

-

Well now I know it is Russian made. And the steel is high quality (Russian high quality). Do not know what '9X?" means? Going to do some research in Russian knives now. Nothing else to do this morning anyway.

-

After some searching, I tried CNK letters that lead me to only one image of it on Ebay. from there i got more info on it. "CNK 9x steel Russian Russia knife" Still looking, there has to be more about this knife elsewhere.

-

I do remember buying the way it was. I just did not know what store I got it at. It was the shape of the blade that interested me. Notice the notch near the handle I think it was to pull nails out a board. Should mention the blade is 2.3 mm thick.

-

I had this knife going 20+ years now. Does anybody seen or know where I can get a couple more of them? I can not remember where I bought it but I feel it was not a pricy tool. I can not make out the tool stamp/logo either. I've used it roughly and it withstood every punishment I threw at it. I use it now for cutting and skiving leather and it does a wonderful job. Not knowing what the tensile is the steel it is a fair steel for cutting but the file does bite into the metal and I was wondering on trying to tempering the metal to see if I can harden it a bit more. Also, replace the plastic handle with a wooden one.

-

Homemade Clicker Press and Steel Rule Bender

abrahamd2k replied to abrahamd2k's topic in Leather Tools

That would be the best way to work bending the steel rules with hands-free. After a few dies, I wish I had implemented that. That will be the next project in the near future. -

Homemade Clicker Press and Steel Rule Bender

abrahamd2k replied to abrahamd2k's topic in Leather Tools

Had an idea for a simple mechanism to apply enough force to bend the steel rule similar to other machines on the market. To my surprise, there is already something similar to what I made... Hopefully, to answer your question, I made it with 1/4 in metal plate, 1-inch metal bar stock and a few 1/4 inch metal pins including a wooden handle. -

When one of my hobbies demand a tool my other hobby skills come to the rescue. Starting out in leatherwork I may not have the money to have fancy equipment but I do have the means to build what I need. Maybe someday I may get into selling more leather creations but for now, I am just preparing in case I do get serious in the future by having fun building cool things now. The die bender is very simple and works well. Using Autodesk Inventor software I worked out a functioning model to build into a tables surface and a handle to push downward to counterforce any table movement that it may cause. I already have an idea to make a different version that will be able to change out the bending points (whatever they are called) and stay out of the way of the bending steel rule on itself by making most of the mechanism under the surface of the table like a few commercial designs out there. The manual clicker press (pictured below) I made after a mini hydraulic press I saw online. Made some improvements by welding the joints solid instead of nuts and bolts (nobody ever takes them apart) for better rigidity and with tighter tolerances on the sliding parts so the press works smooth and solid. Still, need a few tweaking on both machines but overall they were a success for my needs. I would not recommend anyone asking me to make one for them because you can purchase the same class of tools in the open market for the same cost of what I would charge to make plus, the shipping cost. That said, in material cost, the press was estimated 40$-50$ and the die bender was built from scrap I had laying around. I am always open to suggestions and ideas for DIY projects like this that starving artisans like myself can benefit.