Garyspruill

Members-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Garyspruill

-

Thank you

-

I need to ask a quick question due to my personal ignorance, Again, working with the thread companies. For leather Sewing Machine thread: My folks are asking me a question and wanted to come to the experts for the real skinny: The question on the table to me is: do you want: "S" twist or "Z" twist?? Dealing with a poly bonded material, does it make a difference if it is twisted left (S vs Z) or right for our leather sewing machine foils?? Just a reminder: I normally sew all my projects by hand, hence the reason I am asking this very question. They are offering me sizes from a V46 all the way up to the V500's Any help would be greatful Gary

-

NVLeatherWorx Just sent you a PM Thank you so much for testing this Gary

-

Newbie question: Best way to sharpen you awl? 2000 grit? Me: light tap on the irons, awl, stitch. When I am going all the way around a project, I like the unbroken seams, but is a bear with all that thread hanging out while sewing. Personally: I like either the thread I am working on-testing or the Tiger in 0.80 with a JJ 002 needle. It's just what I have gotten used to I guess.

-

porcupine, You can tell me, I am an old fart. Allow me to rephrase: teeth-pricking irons just tell me where the hole should be, then the awl for a tight hole. Line drawn by groover. Reminder: I am in my first year, aka: newbie, am I doing something wrong??

-

We are saying the same thing. You just explained it better than I did.

-

Thanks LetterT I am working with (3) companies right now. 1 in Germany, 1 in France and the last one is in Harligen, TX Which ever one can or does meet what I am asking for and can get the ($) in line to have a workable margin, is the company I am going to be using to have it made. I reached out to the Asian market, and quickly learned: (Texan): this ain't the way to go! The high end companies are all asking for a (+)(-) 5% tolerance, I am working on less than 2%. The Asian market wanted close to 15%? Good pun! Thanks Gary

-

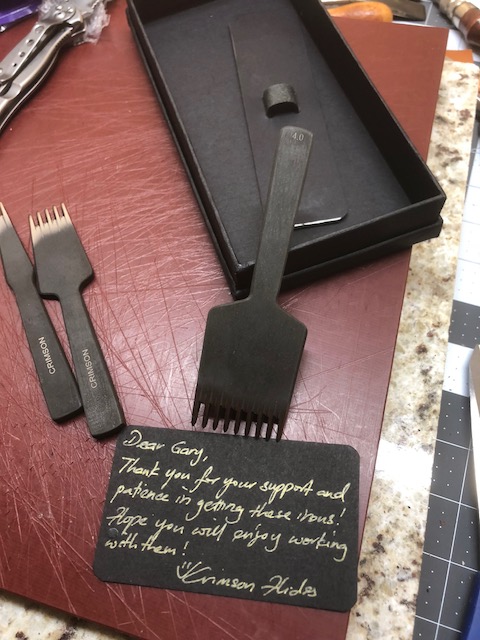

Hey Scoobie, Yes, I hand sew a lot, gets my brain to turn off for some reason? My likes: I like a super slanted tight hole. If I have to use a pair of needle nose pliers to get a single needle through the hole sometimes, its perfect! Using an awl is very common. I like that 40 to 45 degree angle tooth coupled with a tight hole. Makes the thread lay perfect in my opinion. Nothing chunky or rippled with light showing through holes where the thread is. Tight! SPI (stitches per inch) on the new Crimson Hides irons - 4.0 is 7 spi. I own/use sets at 2.7, 3.0, 3.38, 3.85 and now 4.0 (newbies) I do also use a sewing machine for the quickies. Please also note: I am still in my first year at this hobby :-) Gary

-

Hey ScoobyNewbie Understood, this is exactly how I feel Working with (3) companies right now to have it made. Have some high standards for them to hit for both hand sew and machine sew. I see you are from Omaha! Cool, lived there for 7 winters :-) 132nd and Fort area (actually 128th and Fort), lived on the north side of Fort on 128th st. If you want to try some, PM me and will send some samples out at your address. Note: its in raw format right now, no coloring. I have some 1.2mm here that is in sample format. I have already tried a bunch of lines with it, yet know, this is the first group. Gary

-

Logo/Website/Business Card Design

Garyspruill replied to andrewsejlv's topic in Marketing and Advertising

This is funny to read due to the fact, I too am starting to look for a logo designer. I have a person that normally does it for me, but is tied up for the next year. Goodness Gary -

Fun Question: Breakdown: Singapore Dollar: $290 US Dollar: $210.02 Shipping: $45 via FedEx Right at $260 out the door for all four irons. I bought these from the recommendation of Nigal ArmItage. I have already run a few lines with them as a test. My goodness, these teeth are at almost 45 degrees. That thread just lays way over on its side.

-

I spy, hmmm, good eye. Yes, sets of 3.0, 3.38 and 3.85's from Blanchard's

-

-

Thank you alpha2, I will give it a try. I currently use Fiebing's Liquid Glycerine saddle soap. Nothing added to it. Gary

-

Beginnings of the new Leather Workshop Station

Garyspruill replied to Garyspruill's topic in All About Us and Off Topic

Got a tad more done today. AKA.: update Counter top, walls, LED light and craft paper roll done! Pulled a lot of the tools over, now I gotta put'em up :-( Coming Soon: stereo, (gotta have the tunes), skiver, sewing machine, 4 foot work table in front of bench you see. Any ideas that want to be donated, thanks! Later Gary Following forum policy: no images, did not happen :-) -

I will look it up and see the magic, thanks The method I am used to is: water - saddle soap - wax - light sand high grit - paint Gary

-

Got it fredk, Want harder wax, add a lot of carnauba wax, want it softer, add more neetsfoot oil. The ones I have been seeing are almost "white" in color? I am looking for something that makes it easier to apply when burnishing. Gary

-

I have read on several posts and from burnishing companies (folks that sell burnishing wares) that say they have the “perfect” recipe for wax while burnishing. I have about 2 lbs of beeswax with me. Would it be too forward to ask what is the difference (normal beeswax or special recipe)? Anything special to add to beeswax for burnishing, or is it just "snake oil"? Gary

-

Beginnings of the new Leather Workshop Station

Garyspruill replied to Garyspruill's topic in All About Us and Off Topic

Hey Matt From the images, you are only seeing the framing for the main work table that will hold all my small tools, small cutting mate and just all around general stuff. The other table will be in front of it that is 24 inch x 48 inch that is on wheels, on the side wall, there is going to be a clicker press and skiver (consew) and "maybe" a sewing machine, I enjoy hand sewing, but want the option of getting it done fast if needed. You already see the burnisher in the photos. I want to say, there is right at 350 sq feet to work with, have not really put a tape measure to it all the way around yet. Headed back to Home Depot today to pick up the plywood for shelves tops and table tops and lights. Lights, getting all LED, I am done with bulbs. This shop you see is inside a metal building that I have an office in as well. It is AC'd and heated. Which I like :-)! -

Beginnings of the new Leather Workshop Station

Garyspruill replied to Garyspruill's topic in All About Us and Off Topic

Thank you -

-

NVLeatherWorx It would be my honor to send you what ever you wanted or I have to test. I would soak up advice from you like a sponge. I have sent you a private message letting you know my information just in case you ever needed it. Will need your shipping address at some point to send you the samples. Thanks again Gary

-

Hey Ed In TX Thank you for your advice, So in the sewing machine world, I need to be looking in the #346 through the #69 thickness range. Reminder: I personally hand sew. Picking irons and awl. Learning the sewing machine concept is a new world to me. I personally own around 8 sewing machines, but I personally do not use them :-). I want to say they are Juki LU-1508N's with a servo and speed reducer? I can learn, but as stated, new to me. Main focus right now is the hand sewing thread. With my personal sewing machines, I use them on garment goods, 800 Newton material, I use a #69 poly bonded thread for strength and the folks that use what we make, sweat a ton! ED: when we get to that point, you mind if I call you and pick your brain? Thanks again Gary

-

Hey chrisash, I understand Tiger Thread is a branded name of quality, I am the same as you. This is what I personally buy-use myself for the very same reason. I also know I would be a no-name company going up against a company like Nike. It's tough - coupled with small margins. Far East production: would never even think of this. I am working with companies here in the US and in Europe to get the tolerances and quality that would match what we all currently use and like or "better". The base line from me to these companies is pretty high, and most of the companies are fighting me. I have set some pretty high levels to them. It's very close to a darn boxing match with some of these companies. Gary, you just can't do this, OH yes you can. If I do this project, I can only hope to some day sway you to change your mind or at least give us a fair shake. That is all one can ask for. Thanks again chrisash