DSloop

-

Content Count

35 -

Joined

-

Last visited

Posts posted by DSloop

-

-

Nice. How well does the mouse work on leather?

-

You just learn by experience setting the tension, it don't take long.

That was an interesting video. I have two hooks, one a 35 dollar Chinese brand and a Simanco original. The Singer has more metal in the area where the thread was slipping off the hook in the video. It is about 3 mm longer there. I wonder if that has anything to do with it?

-

tighten the bobbin until it will not slide. these things like tension. thread take up spring is set at medium. How did you time it? there is a very good video on youtube about doing that. the author describes everything clearly. search for 111w155 setup/timing/maintenance..

How is the hook? nice and smooth and very pointy?

The point of the hook should be 1/16 of an inch above the needle eye as it starts back up. It should be moved as close as possible to the needle without touching it.( I think that's how it goes)

-

Bobbin tension kinda stays the same unless you go from light to very heavy thread. Did you set it where the thread is resisting being pulled from the holder? It should not be loose, but offer good resistance.

Check ALL of the guides and little holes where the thread runs thru.If there is even a small groove for the thread to catch it will mess everything up. Get a good magnifying glass and check those out, along with the tension discs. I don't run the thread thru the small guide at the foot, it runs just fine with out going thru it.

I adjust the part in image 4 so it lets the thread thru freely, it don't require a lot of attention. (I think).

Remove the take up discs off as a pair, but leave the spring on the machine.

Wind the thread take up spring around clockwise 1 turn then put the discs back on. This can be a pain, make sure you don't trap the little spring with the discs, there is a shoulder back there for it .

Good luck.

-

5 hours ago, Sugarkryptonite said:Yup! I made sure to do that. Also I noticed that on the stitches, the thread is at a slight angle between each hole, maybe like 10-15 degrees. Probably unrelated but still a problem. Brand new needle.

One of mine did the angled stitch thing too. Try adjusting the upper thread tension and see if that helps. Start with almost none and put more tension on the thread as you slowly sew.

-

I live very near Gastonia, and have two Singer 111 w 155 machines for sale. They are in good operating condition, with L shaped tables and 1/2 hp motors that use 120 volts. I will let you pick the one you want for $500.00 and I will deliver and help set the table and machine up.

-

Make me an offer and lets see how close we are in thinking. I did research and learned they are like unicorn teeth.

-

Are you holding the threads taut about 6 inches back from the foot when you start sewing? Not banjo string tight, but snugly. These machines need that bit of help, to get the first stitch started.. Mine does, anyways.

-

I responded to an add on my local Craigslist for "Industrial sewing machines for sale". The picture was of a Singer111w155 and a table, at a decent price. I went and looked at the machine and bought it. It had been sitting on the floor in a basement that was used as an upholstery shop, for a couple years, so it did have some light surface rust and the usual grime and spiderwebs. I cleaned it with BrakeKleen and polished some of the nastier spots. After oiling everything up and making sure it would not destroy itself I put it on the table where my 111w115 was, powered by a servo motor. After some more tweaking it runs like a champion. This is good, right?

I talked with the lady that was selling the machines ( her dad had died suddenly a couple years ago) and she was wanting to clean the basement out, as it had become a hoarders dream or nightmare. Her father bought any and everything that interested him and there is a lot of stuff. I made a deal for the other two 111w155's and all of the leather, fabric and anything that was used for the upholstery shop. Two machine two huge L shaped tables, four motors and a pile of other things. Still need to make a few more trips to get it all.

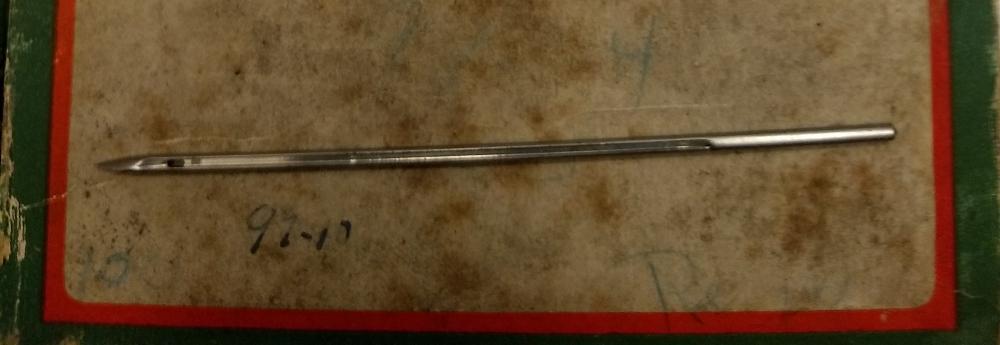

In the goodies were some NOS Singer needles for a 97series machine. The hand printed label on the boxes is faded badly, I might be reading it wrong. Here is a picture. These needles are for sale if anyone can use the m, I cannot. There are 77 of the smaller leather tip needles -3.044 inches long, .065 diameter, and 23 of the larger fabric needles, - .092 diameter and 3.030 long and one oddball that is .100 diameter and 2 .744 long.

The upper box has 97 x 3,- 26 on it, the lower box has 97 x 10. I cannot see a thread size.

Image # 2

.thumb.jpg.92002562475fd042170c2a6be158bded.jpg)

Mouse Pads

in Purses, Wallets, Belts and Miscellaneous Pocket Items

Posted · Report reply

I'm gonna try that.. thanks for the idea.