DirtyDusty

Members-

Posts

91 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DirtyDusty

-

I am wanting to do a straight up binding. Are you saying to do it like Watts video for Cheyenne roll, but leave it sticking up? The stohlman method has the cantle filler on the back side.

-

So, I am going off 2 different resources for saddle construction, besides the help I am receiving from here. The Watt video and the Stohlman book. Watt is doing a Cheyenne roll so obviously the procedure will differ. I am using a tin strainer, so would i cut the final ground seat layer to fit the entire inside of the cantle? The Watt video shows cutting it back inside the dishes, and adding the cantle filler to the inside of the cantle. Stohlman shows adding the cantle filler back side, before adding the cantle back. I can’t find any instructions for a straight up cantle. Other than the stohlman book, but they are doing all leather ground seat.

-

i remember reading somewhere on here, where someone was discussing the cantle height and width should be considered when deciding wether to go with a Cheyenne or a straight up binding. I don't remember who it was, but I got yo thinking about my saddle I am building. I was planning on a straight up cantle, but I ordered the tree 4” x 12.5” cantle. Is this going to look out of place with a straight up cantle?

-

That’s the style I was looking. What did you use for a background stamp?

-

The stohlman book has tables for fender length and stirrup leather relationship, depending on which hardware is used, is it accurate? Or is there a better chart for determining fender length and stirrup leather length?

-

Superior Stirrup Leather Buckles

DirtyDusty replied to bruce johnson's topic in Saddle Supplies, Tools & Trees

Will the superior buckle work with twisted stirrup leathers, the sand as Blevins? -

Anyone ever line your flat plate rigging with raw hide? I saw a custom saddle one Facebook that said the plate rigging was rawhide backed. Just wondering what the pros and cons would be.

-

I understand what you are saying. As far as rigging I was looking at doing a dee rig in the 7/8 position. Like the Al Stohlman dee rig. Figured it would help keep it lighter. I am using 13/15 skirting.

-

So instead of a straight dotted line, make that cut an arch, to spread the transition?

-

So getting my patterns made and starting to layout, using the Jeremiah watt method. Came to my next question. In the video he has a triangle shaped riser in the front of his plug. When I laid mine out, there isn’t much room for the front to go all the way down. As you can see by the dotted line, I will be running part of it up in the fork. Is this correct? In am thinking I need to just slice that part till it blends, and go all the way to the bottom of the bar.

-

Thanks for taking time to responding. Makes a lot of sense. On a side note, I like that border you used in the saddle in the post. What size and style of stamp did you use, if you don’t mind me asking.

-

How short can the skirts be in the back? I notice several manufactures have their overall skirt length on mule saddles at 24-27” for a 16” finished seat. My tree is 24” alone.

-

I have seen several comments, on different videos and posts, that say the angle of the rise is usually determined by what the customer wants. Looking at some pics of custom saddles, most I have looked at have a low, gradual rise. While I have seen production saddles that are steep rise abruptly. What are you thoughts on the pros and cons of the rise on the ground seat.

-

I have one pattern made already, like the stohlman book shows. I think I will modify it some. Pondering how to work around my stirrup strap slots. I think I may have an issue with the slot under the tree being too narrow. I am gonna cut my straps and see if it looks like it will work.

-

What’s your preference on mounting breast collar dee’s and other small Dee rings? Rawhide, pre made metal tabs, or leather? Pro’s and con’s of each?

-

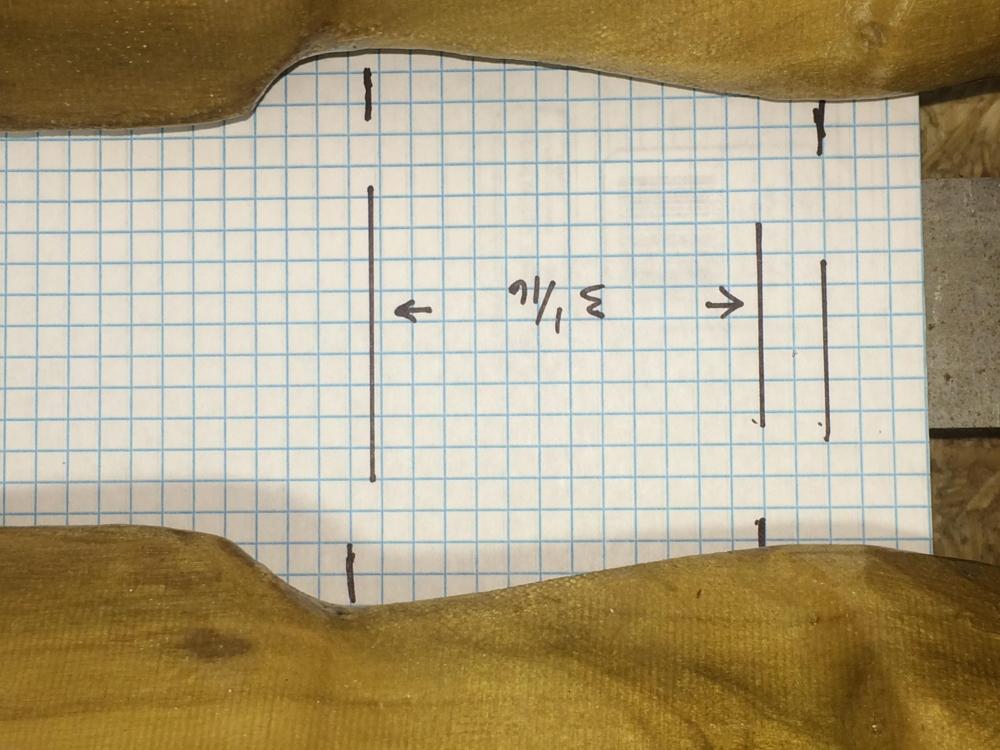

So as most of the guys who have been commenting on my post and helping me out greatly know, I am trying to build my first saddle. It’s for a mule and I ordered a HF tree and it had issues. So I went the custom route and ordered one, which came in this past fall. Due to time issues, I am just now getting back on this project. I been watching the Jeremiah Watt video and learning from it too. I started laying out where my stirrup will lay on the tree. Using the method that Jeremiah Watt uses, he suggest 3 3/8” clearance fir a 3” leather. He also says they should be squared to each other. So as I started laying out on my tree I find I can’t square them up perfect because of the stirrup slots being slightly offset from each other. If I split the difference I end up with almost 3 1/16” but the edges will be riding on the radius of the slots. Am I over thinking this and trying to be too perfect?

-

What’s the best thickness to use? I have some spare 9/10oz I was gonna use, but wasn’t sure if it would be too light.

-

I am in the process of making my patterns. In the stohlman book it shows the fender leg departing at a forward angle, If the fender was hanging down. Is this normal or is it one of their designs they preferred to use?

-

Do you happen to have a link to the article?

-

What diameter and size of ss ring shank do you use? I found several styles online. Cedar siding nails 1” and up, and roofing nails with s big head. 2d I believe.

-

The pics help a lot. Is there any modification to the Stanley spoke shave? i have the Jeremiah Watt videos coming in. Dusty Smith sent me a message Friday and said my tree is shipping out this weekend. Made me a round knife while I was waiting. Along with a lot of knife sheaths, to practice stitching and tooling. Things are starting to come together.

-

What’s your favorite rust preventative for tools on your bench. Made a sheath for my new round knife, let it dry for a couple of weeks before I put it in, but it still rusted in a couple of spots. I was using ballistol oil on it.

-

I got the watt dvds ordered. Tree should be getting close to getting made. Went with Dusty Smith and he was @3 months out 3.5 months ago, So hopefully it won’t be much longer. Already had ordered 2 13-15 HO from panhandle, along with a sheepskin. Already have my hardware, except fir nails and tacks. Could you steer me in the right direction on sizes and suppliers. The Stohlman books call for blued tacks, but I have seen many in the forum suggest stainless.

-

Superior Stirrup Leather Buckles

DirtyDusty replied to bruce johnson's topic in Saddle Supplies, Tools & Trees

Ok, thanks. -

Superior Stirrup Leather Buckles

DirtyDusty replied to bruce johnson's topic in Saddle Supplies, Tools & Trees

Hate to ressurect an old post, but I couldn’t find the answer anywhere. What thicknes do the 2 sizes cover? I see 2 sizes listed on several sights. They just say fir thick leather and medium thickness. What oz. range would that equal?