Workinman

Members-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

SoCal

-

Interests

Wet Molding, tooling & stamping.

LW Info

-

Leatherwork Specialty

Coasters, Key Fobs & Valet Trays

-

Interested in learning about

Dying, Coloring & Finishing.

-

How did you find leatherworker.net?

web search

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Workinman's Achievements

Member (2/4)

-

Thank You everyone !!! I now know what to buy !!! I really appreciate your help !!

-

Thank you PurpleFox & TomE !! So, when I went to my local Tandy store (not super helpful) they had mainly sheepskin rugs. Would those work, or should I ask for some other type of sheepskin product ? As you can tell, I'm a newbee ?!?!

-

I want to make a rifle holder (?) for my daughter as a Christmas gift. I have a beautiful leather hide, but want to line the inside with sheepskin. My question is - what kind of sheepskin do I look for ? Thank You !!

-

Hot Foil VS Hydraulic Press for volume stamping

Workinman replied to Workinman's topic in Leather Machinery

Thanks for your comment ! Before I bought the 12 ton press I looked into buying an Arbor press. Since my images are approx. 3.5" in diameter, I felt the arbor press would be iffy. I like the mod you made to the ram on your press. You wouldn't happen to have a photo you could post ? Also, what kind of company made that mod for you (welder, fabricator, etc) ?? Thanks again ! -

Hot Foil VS Hydraulic Press for volume stamping

Workinman replied to Workinman's topic in Leather Machinery

Thank you, Mike. I agree. I do case my leather as it seems to leave sharper impressions that I think are visually appealing. However, that introduces another variable- moisture content ?!?!?! Frankly, if I can solve the other issues, the pressure is something I can deal with, like you said. Get an approximate pressure for each image, note it and start there when stamping that particular image. Should be close enough to not slow me down too much. To all- I do appreciate the effort and trouble you went to in giving me your advice !!! Mike -

Hot Foil VS Hydraulic Press for volume stamping

Workinman replied to Workinman's topic in Leather Machinery

Thank you all so much for taking the time to offer such detailed suggestions !!! I really appreciate it ! Since the die and leather piece are mobile (not fixed to the press), I think the suggestion Mike Batson offered re creating a jig. The way Mike described creating the jig will work for me because each of dies are square and can be set up using a "poster child" of each image as Mike described. As for the pressure issue, since my press is hydraulic (not pneumatic), I will look in to adding a pressure gage. If that isn't possible, I will upgrade my press to a pneumatic press- which does come with a pressure gage. A guy at the local Tandy store also suggested that I look at the dies to see if they are warped, since I am using a 12 ton press. He thought my dies might need to be a little thicker to press more evenly (just throwing this out there if case any of you encounter another another newbie like me Thanks again everyone !!!! -

Hot Foil VS Hydraulic Press for volume stamping

Workinman replied to Workinman's topic in Leather Machinery

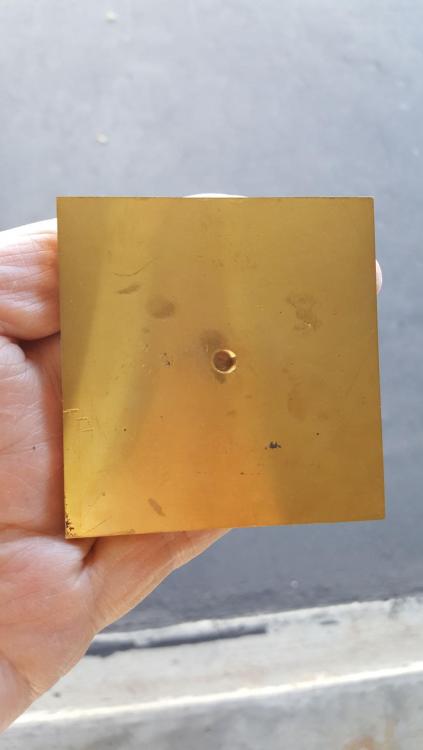

Thanks Burkhardt and Mike Batson !! I probably overcomplicated this. I don't have any (current) plans for stamping with foil, so, the only point in mentioning a hot foil stamping machine was a result of a conversation I had with a friend who also dabbles in leather. My only "need" right now is to speed up the stamping process. I currently use a 12 ton Harbor Freight hydraulic press (see photo). My stamps are brass (see photo) and are made by LeatherStampMaker here in SoCal. Everything works fine, except the alignment (very tedious) and pressure (sometimes the image is too light, sometimes too deep, sometimes deeper on one side than the other, ......). If I stamp 100 pieces, I will get 8-10 that are unsaleable (not horribe). BUT, it might take me 3+ hours to stamp those 100 pieces. BTW- The magnitude of the problem is much greater than described because I have two different product lines with 8 different designs for each. So, in a typical month I might need to stamp several hundred pieces. Appreciate your suggestions !! -

I've been stamping key fobs using an 11 ton hydraulic press. With (tedious) alignment time spent on each piece, plus making sure the image is even, I can spend hours stamping 100 pieces. I hear a lot about hot stamping machines, especially relative to higher output. So, my question is, would I be better off paying for a good pneumatic hot foil stamping machine, or a good pneumatic hydraulic press ? Sorry if this is a dumb question. I'm relatively new to all this Thank you !!

-

I've been wet molding leather trays using a stainless steel bowl, and a Pyrex casserole dish purchased on a local junkin trip. Unfortunately, the bowl makes a tray that's too small, and the Pyrex dish is also about an inch too narrow for what I need. I'm planning to make molds out of solid wood , but am not sure what to seal the wood with ? Thanks for your suggestions !!

-

Thanks Tom. I'll give it a try.

-

Thanks Tom and Alaisiagae ! Tom, how would the lacquer affect the leather- other than the waterproofing ? Would it darken it, stiffen it, or, leave a shiny film (like Super Sheen does) ? Thanks again ! Mike

-

Those are awesome...at any level of skill, let alone your first solo project ! Great job !! I'm curious how your waterproofing is working ? I also make (veg tan) coasters, but noticed they begin to stain really badly after a few weeks of use. Coffee and wine seem to be really bad, but even water leaves a stain. I've experimented with; 1) Fiebings Leather Balm; 2) Tandy's Eco Flo Super Sheen; 3) Tandy's Eco Flo Top Finish; 4) Mink Oil; 5) Saddle Soap, and; 6) Dr Jackson's Oil for Leather- ALL recommended by Tandy and Fiebing. I've even experimented applying each on to dry leather, cased leather with 1 coat to as many as 4 coats. NONE work perfectly (of course, some better than others). Also, most leave a shiny film on the surface, which for my coaster designs is not desireable. I'm sure open for suggestions any one

-