-

Posts

97 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LiftPig

-

@Icho & @Moti did you get this problem resolved? I'm having similar problems and it seems to be not-too-uncommon with 341 clones. I got some good advice from @Wizcrafts & @kgg utilizing @Uwe's videos and the problem has improved significantly. I have one more adjustment to make this evening and I'm pretty convinced that this issue is going to go away once I do that.

-

Update: I moved the bobbin opener back as much as I can without causing a bind. The manual is really vague as exactly how to set it so I used @Uwe method of setting the tab in the middle of the slot when the thread reaches 3 o clock and then a touch more. I also changed the swing and tension of the check spring to give the top a little more throw. I would say the noise of the thread getting caught beneath the bobbin case has reduce about 50%. I did a few test stitches that looked pretty good but then had to leave for work. I'll test some more today. @Wizcrafts you mention in a few other threads advancing the timing a little bit (a couple degrees) when someone else described a similar problem. Would that be helpful? I have my timing set in the method that @VanPlew describe in their youtube video. I recall seeing a post from @Uwe saying how he likes to time based on hook position rather than a distance above BDC but now I can't find it again and I don't remember which position he mentions. I think it's having the hook tip at 7:30 when at BDC but I can't recall exactly. The aforementioned @VanPlew video:

-

The thread is same size top and bottom - 207. It happens with all threads pretty equally. I did once think it was a black thread issue (of which there are many) since most of my sewing is black thread but that's not the case. Wow these are great manuals. Why aren't the ones that come with Cobra's this good? Thank you so much!! Wiz and KGG - Thank you for the advice and videos! Looking at the 341 video compared to mine and breaking them down frame by frame, mine is under way more tension. I'm betting that the take up spring and/or bobbin case opener are mal-adjusted. I'll work on those adjustments and report back.

-

I can tell you what I do - it might not be the According to Hoyle right thing but it works for me. I set my tension for the thinnest part. Now I know the knot is somewhere in that thin material. Theoretically, going up in thickness should leave the knot in the same general place, and while it may not be right in the middle of the layers, it's buried. You could also give the tension knob a couple clicks tighter when you go up in thickness, keeping track of how many times you do that, and then go back down if the material gets thin again. When my machine is sewing well this works - I might get one wonky knot that just shows right at the transition between thicknesses but I can poke that down with a blunted awl.

-

Hi KGG I've had the machine about 18 months. I always thought the noise was the spring on the third tension disk (check-spring?) resetting and the knots were something I was doing. I slowed way down, watched the spiral exercise videos on YouTube, practiced a lot, and was very careful about technique and still have issues. It wasn't until the gentleman I spoke to on the phone said he heard the twang and had never heard such a noise coming from a 26 that I started investigating where it came from. I did look through the thread you linked - his noise was some sort of squealing coming from the shaft - mine's something else. I haven't talked to LMC yet. My work schedule has me working when they're open. The good news is my schedule changes in a couple weeks and I'll have Friday's off to call them. Here's a link to the sound:

-

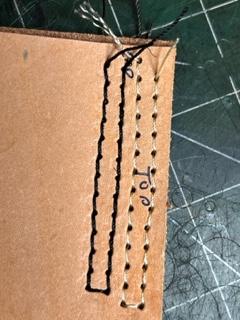

Good morning everyone, I'm having some trouble with my Class 26. I'm usually running 138 or 207 top and bottom through 8-16 ounces of firm veg tan. I use a 23 needle for 138 and a 25 for the 207. I'm getting inconsistent stitch tension and the occasional balled up knot/loose stitch that isn't pulled up through the piece. This is especially true going around any type of corner but as you can see in the pictures it happens in the straights a lot too. The pictures below are 207 through 8 ounces of veg on a 25 Schmetz tri point needle. I've cranked down the tension until every knot is on top and it still happens. I've cranked down the pressor foot as far as it goes and it still happens. I've raised the needle until its barely in the leather before making a turn and it still happens. What's most frustrating is that it's so random. I'll get two or three stitches that has too much top tension, then two or three that have two little. I spoke to a guy who is well established as knowing these machines well and we worked on tension, bobbin tension, cleaning out the tension discs, changing needles, rethreading the machine, different threads, looking at timing, and technique. We were on the phone for about three hours and at the end he said "I can't think of anything else to help you, you might be screwed". One thought I have is that when the thread pulls from under the bobbin case it makes a loud popping sound. I have a video of it but it's too large to embed here. I've scoured the internet looking at videos of sewing with a 26 and with only one exception, nobody's machine makes that noise. It seems logical in my brain that the top thread getting caught under the bobbin case is going to make a tension issue as the take-up lever raises. I've taken apart the race to look for debris but haven't found anything. The machine is well oiled. Could this be my culprit? I'm at a loss. I do know that I have a backlog of orders and a machine that's making loose stitches that have to be-resewn. I am extremely grateful for any help or insight. Cheers, Jordan

-

When I wet form holsters I dip it for about 7 seconds in ~2c luke warm water with 1 drop of dish soap (breaks up surface tension). I then let it set for about 5 minutes before introducing the pistol. This is using 8-10 ounce very firm veg tan.

-

It comes with some manner of high-density closed cell foam. Doesn't say what the density is. It's made for Kydex. I imagine it would get at least a beginning impression made that could then be sharpened with normal techniques.

-

-

Good morning all, I have a customer who would like something built similar to this picture. I've heard that it's called a "Montana Rig" but I'm not sure if that's right. Does anyone have a pattern for this? I know I could sit down and make one, but if someone else has already gone through the trouble, I'd rather support their endeavor. Thanks in advance.

-

Hello everyone, I've resigned myself that if I want to make this belt the way the customer requests, I'll need to have a custom stamp made. I don't need a big expensive brass stamp. Delryn will work. I'm willing to bet I only use the thing once. I need the stamp to be no larger than 1" tall (going on a belt). Here's an example of the art. If you have a better sample of a Northern Flicker that would look better, I'm all ears. If anyone is willing to make this for me (and have it to me in California, USA within 2 weeks or so), please DM or respond to this message. Cheers,

-

That should work!

-

I have a customer who wants a Norther Flicker (it's an irritating bird that knocks holes in houses. It's one of God's lovely creatures) placed on the inside of a belt. I've looked at some line drawings and I can draw the thing but I'm not sure how well it's going to come out once it's carved in a space that's only 1" high. I guess I could have a stamp made but I'd rather not, as I doubt I'd ever use the thing again. Anyone else have any ideas, or a stamp for a woodpecker type thing I could borrow/rent?

-

It looks good NOW but my concern is that all this product will come out when it gets damp from use in some dudes back pocket. Some of the horror stories I’ve read has me concerned. That said, when I got home from work today I oiled the leather a bit and nothing came up on the rag so that’s encouraging. Funny reading suggestions for Pledge with Future. I used Future Floorwax to seal model airplanes until the product was discontinued. I swear the outcry from that was what made SE Johnson reintroduce the brand.

-

Also, check to make sure there's nothing jammed up in the bobbin compartment. Even a little piece of thread will gum up the works.

-

So, I'm making a wallet with the intent to try to sell it. I happened to watch a video on YouTube of George Hurst using Eco-Flo All-in-One on a belt and thought "that came out looking great". So I went and bought some, cut my wallet, drew my design, did my tooling and applied the stuff. I agree it looks fantastic. Very easy to work with, deep color and a very nice satin sheen left at the end. Now, this morning I was looking to see what to use to seal the stuff and have read the horror stories of it bleeding out and making a mess of things. Now, my question is, should I bother trying to seal it or just toss the thing and start again? I don't want to sell a wallet and have a customer be unhappy because the dye that should be in his wallet has soaked out to his skivvies. Has anyone used this successfully? I wish I could use Feibings Pro-Dye but I'm in California and can't (this state.....).

-

I totally agree w/ the AC. I live in Northern California (Butte County). It gets hot in the summer. I think a wall or window unit AC is a must, not only for comfort but to protect my leather and supplies from getting baked. I think a base-unit 12x10 will work. I can install a couple windows and run the romex myself for power. How do you keep the critters (I'm mostly worried about rats and mice) out?

-

My new house is about 50% complete being built. I've decided to move my leather shop out to a tuff shed type situation as soon as we move so I can work at night and not bother everyone with the tap-tap-tapping. My question is, for those who are working out of one, how big is adequate and how do you have it set up? I think an 8-10x12 would probably be okay. I'd like to have a full 4x8 sheet of plywood as my cutting bench so I can lay a side out and have room to cut and maneuver. Eventually I'll have a sewing machine and table. A small space to tool (or just put my granite on the cutting table) would also be nice. That and some storage should do it, right? Thanks in advance for the replies.

-

Has anyone tried using vinyl cut-outs as a mask for dye? I have a client who wants his company logo on some leather. It's too small and intricate to carve, at least with my skills. I was thinking if I made a vinyl cut-out of his logo, stuck it to the leather, and then lightly airbrushed several light coats of dye, I could get the logo how he wants it. I realize a laser etcher would do this but I don't have one nor access to one. I do have access to a vinyl cutter, though. Just curious on everyone's thoughts.

-

Which setter do you have? I've been looking at various models. I'd like something that can set double caps, tube rivets, and line 20/24 snaps without crushing the hell out of them.

-

JerseyFirefighter, I'm assuming from your handle that you're in the business, too. I didn't want to use the Rivet/Burr combo since they're so big, and really an overkill for these. But you're as aware I am that firefighters are hard on their things. I don't trust sewing and glue alone to hold things together that need to be structural and might be subjected to heat, solvents, high stress, and other nasties. I'd prefer the cleaner look of a double cap, though. I might make some test pieces and pull them apart with a come along and see what fails.

-

A better black?

LiftPig replied to LiftPig's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Cost mostly. An undyed side is about 25% less expensive. If I can't find a good way to get black leather that is color fast, I'll have to buy pre-dyed black and adjust my prices a bit. -

A better black?

LiftPig replied to LiftPig's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Hell I’ll try this just for the fun of it. -

Do you know how tube rivets compare to double caps for strength?

-

I make a lot of black items for firefighter gear. I've been using Angelus Jet Black cut 50/50 with rubbing alcohol, allow to dry fully (I usually air brush), oil with a single heavy coat of Neatsfoot, allow to dry, then a coat of Leather balm w Atom wax. I'm still getting a lot of rub off. The dye looks nice and the leather is nice and supple but it seems I can't get the dye to stay where it belongs. Anyone have some advice on a different product I can use to hold the dye down? I can't use Feibings Pro Dye because I'm in California...unless someone knows a retailer that's willing to sell it to me.