TonyGreen3455

Members-

Posts

63 -

Joined

-

Last visited

Profile Information

-

Location

UK

LW Info

-

Interested in learning about

Learning leatherworking A-Z

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

TonyGreen3455's Achievements

Member (2/4)

-

thanks a lot to everyone for your help

-

looking to buy it can anyone prove - does this reducer (box one) have a bearing on the axle?

-

troubles with cb3500 threading on upper tension

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

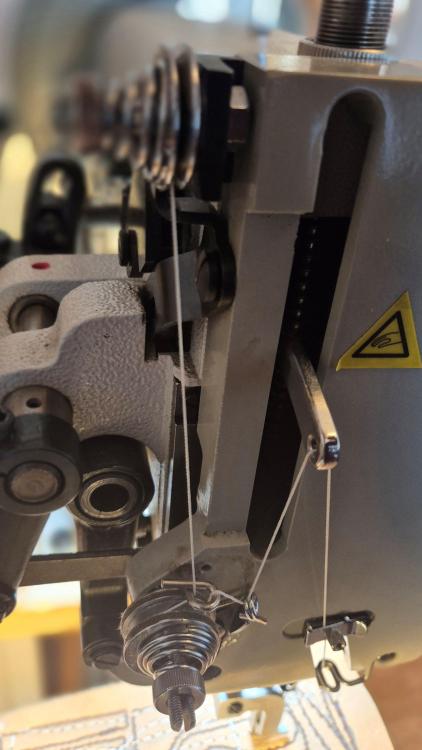

followed all recommendations and on top of that moved thread guide before the upper tension a bit down, just below the axle of the tension itself - see pict. very happy with a result, whatever it's a right way or not. many thanks to all again. coda -

troubles with cb3500 threading on upper tension

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

those pict with a thread on the top taken after that. at the beginning put it in between plates completely down - it is why a bit surprised with such issue. confused - thread itself is either too thin or slippery many thanks to all for your opinions - will try it -

troubles with cb3500 threading on upper tension

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

you mean - this one? threaded as per video - through single hole, but will try it for sure, thank you! -

help needed a bit strange issue, I can't even describe in which area exactly - the threading, the tension or machine itself. cb3500 clone. the thread 207/15 the thread, which is initially threaded as usual (via correct way, I hope) when sewing, jumps out of the upper tension. just comes out from between the plates and all the tension disappears. was trying different ways to thread, screwing tension/plates up - all the same. thread 207 does not want to be in between the plates when sewing. imho most logical way to fix it - to put extra thread guide after the tensioner, but there in no any hole/screw to connect it at all. no any way by the design. with a thread 277/10 no such problems, everything was fine. so, where I'm wrong? or it is hardware issue and smth to be replaced/fixed/installed? any advises welcome

-

slide plate CB3500 machine

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

Patrick, many thanks! -

slide plate CB3500 machine

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

the irony is that I was asking and from this seller as well (on aliexpress) - do they hold screws for such plate? alas, Constabulary needed ) thank you, will try it many thanks to all - will try those Singer screws or will re-tap the plate coda -

slide plate CB3500 machine

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

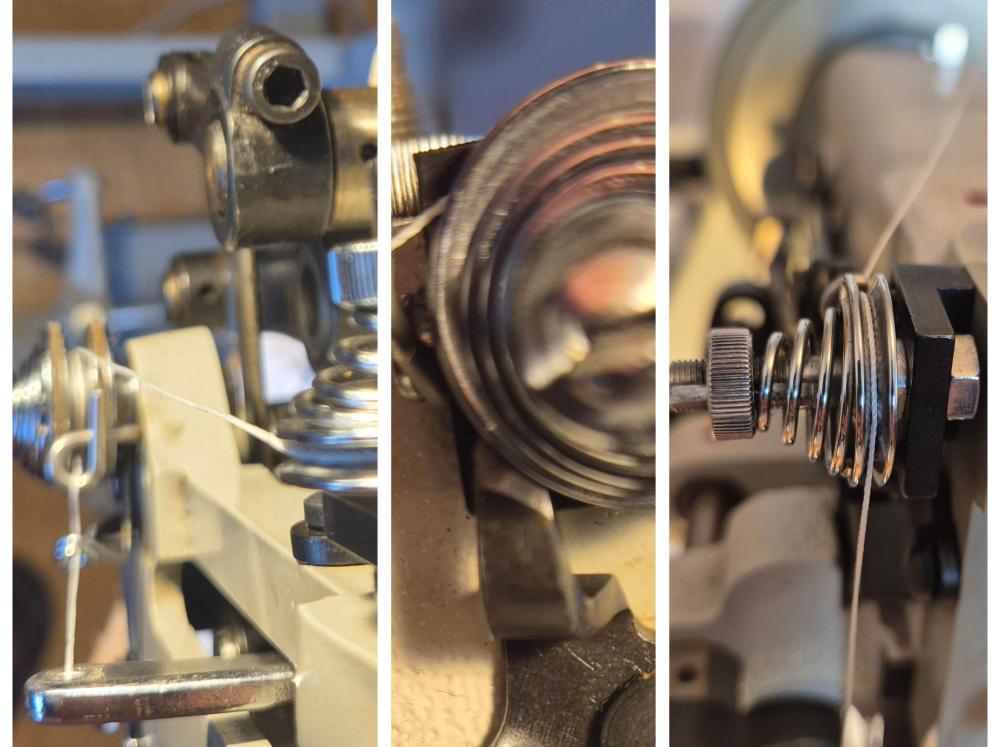

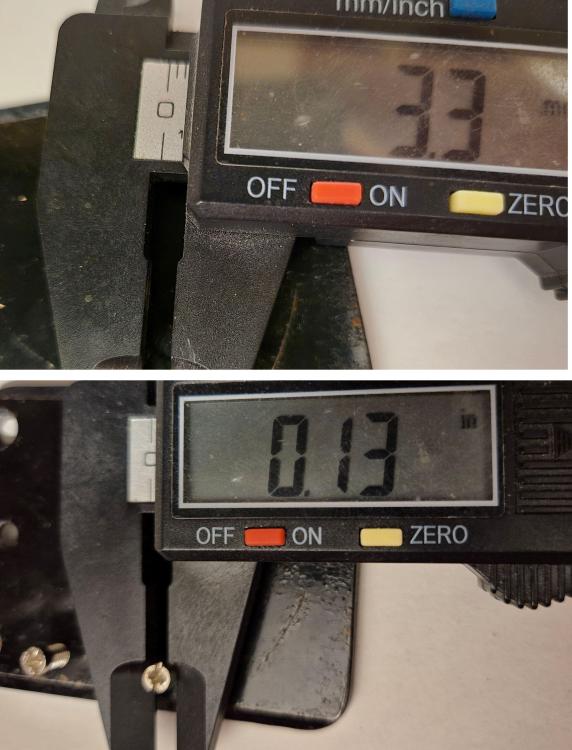

asking due to even living in imperial/metric country can't find proper screws mine is smaller than 11/64 - see photo and another issue - there is no problem to order this piece of metal - from dealer or ebay. but they all come with no screws and I have no ideas where to order it? I mean - compatible with the plate. CKPSMS has similar screw 11/64 or near, but no plate. and I didn't find such place to buy a set - the plate with screws. so, no one who selling plate will guaranty me that other "third parties" parts will be compatible with their one. circle closed. looks like the simplest solution - re-thread holes -

Needles again Having CB3500 clone - can I find 794 needles for sewing leather smaller, than size 160LR? 794 140LR - does it exist at all? Otherwise - sewing with 794R size 140 - it's not counted it as a "heavy" sewing, therefore we can use regular R point needles?

-

hello sewing guru help heeded CB3500 slide plate - does anyone can tell me which thread size on those 3 holes for fixture? any dedicated places to order special bolts for it? apart of "sewing machine bolts" - do these bolts have a special name? what I have to google for? about the plate - shape like this only? no other versions? regards

-

Narrow feed dog FLAT Plate for Cowboy CB4500 and Cobra 4

TonyGreen3455 replied to Patrick1's topic in Leather Sewing Machines

Nice stuff! have not found the roller guide on your shop - is there any chance to get it as well? -

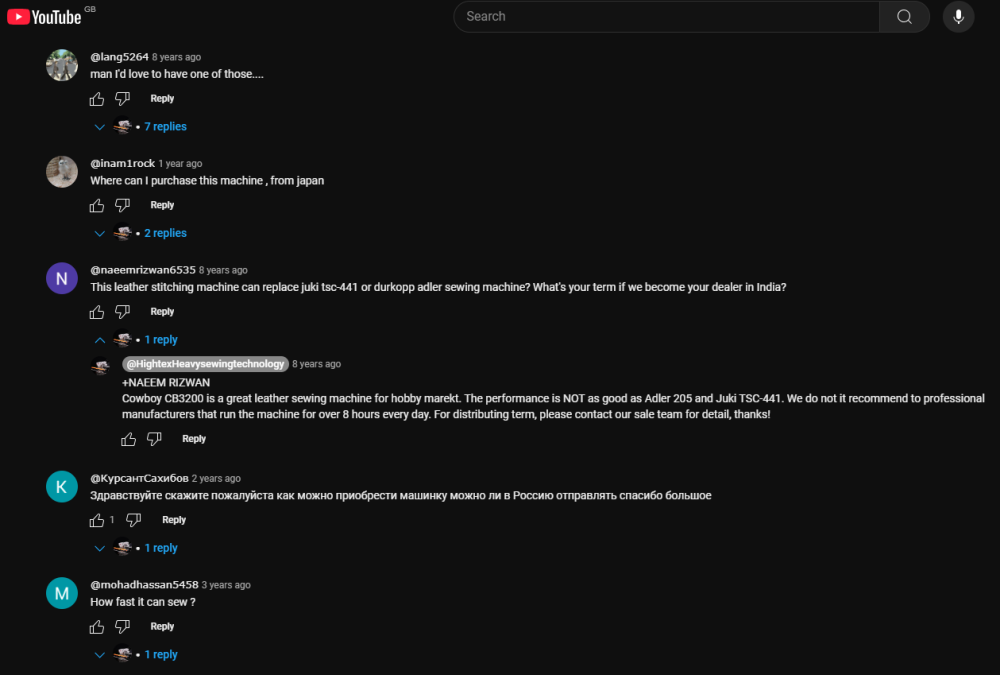

Cowboy CB3200 and its "performance"

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

old story actually, but anyway you right - with my semi-hobbyist usage it shouldn't be an issue, but... -

digging the net for some info, found this phrase from hightex guy: "Cowboy CB3200 is a great leather sewing machine for hobby marekt. The performance is NOT as good as Adler 205 and Juki TSC-441. We do not it recommend to professional manufacturers that run the machine for over 8 hours every day." for some unknown reason I'm hearing behind these words - it is weak semi-domestic machine with some alu or plastic inner parts which can't run for a long. CB3200 owners - can you prove or disprove it? I'm not running my machine even for 2 hrs per a day anyway, but after this have to think twice. otherwise - what performance he is talking about? and BTW - can you recognise CB3200 seams? DA205? 441? is there any visible difference on the final results?

-

Singer 45K online - weak points and what to avoid?

TonyGreen3455 replied to TonyGreen3455's topic in Leather Sewing Machines

first of ALL - thank you for your reply You right - Adler 205 clone. cylinder arm. https://www.ebay.co.uk/itm/355819813297 no responses from the seller at all. IMO - low price. Sinfer 45K. https://www.ebay.co.uk/itm/186763222897?mkevt=1&mkpid=0&emsid=e11051.m43.l1123&mkcid=26&ch=osgood&euid=1401378251254ee6ab69110b35ab10d0&bu=42983703480&osub=-1~1&crd=20241105122732&segname=11051 got a message from the seller - selling machine for his father and has no clue about it. vas very tuff in communication. this one a bit closer to me to see it first - should I go to see them and to which one? second - once arriving - what to look for? yes, I'll take my lightest and heavieast leather/threads to try and a my common stuff as well, but from the mechanical side - where the weakest places (especially for S 45k)? I have DA669 already. trying to find a machine for heavier leather up to 15oz and/or for leather edge binding. have to make a decision, but need some advices.