newfieboy

Members-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by newfieboy

-

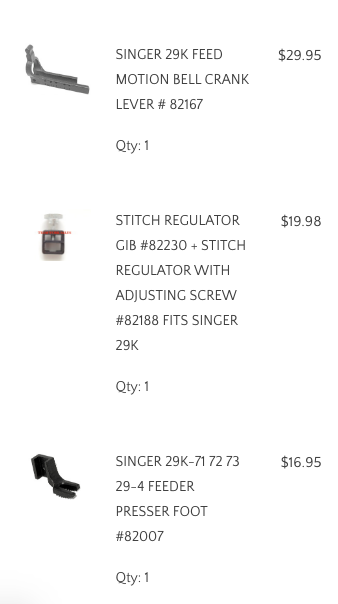

Hello, So I purchased motion bell crank lever, stitch regulator assembly, a new feeder foot along with some other parts (take up lever, lifter, bobbon wheel, ect) and it seems as if the stitch length got worse. The only thing I could change is the feed motion ring slide bar but it doesn't look to be worn all that much. I followed the instructions of a fellow sewer on here for stripping the head down to which I gave a good cleaning and re oiled. Everything looks to be in good shape with little to no wear other than the motion bell crank lever. I brazed the old motion bell lever to see if it would fix some of the stitch length problem i've been having before I ordered the parts and invested any more money and time and it seemed to increase the stitch length from 7-8 SPI to 6~SPI so I went ahead and ordered the parts but when they arrived and I reassembled it seems worse than before? The presser foot seems to haul the leather in a circle which did not happen before. Ive checked the gib and stitch regulator to make sure it was facing the right directions to no avail. The only way to receive any extra stitch length is to move the lifting lever shaft to the H position to where I get a little bit of distance but no where 5SPI. I have searched all over the web for tips to remedy this problem but im at a brick wall. ANY and ALL info would help! Thanks to all that helped so far!

-

This is my foot with the worn stitch regulator. IMG_2352.mov

-

do you guys (and girls?) think that buying these parts would help with my stitching length problem? I have noticed that my stitch regulator is really worn and leaves the foot with to much play. With a new stitch regulator and gib along with a new feed motion bell crank(for the price its easier) Im thinking it will improve drastically. Also a new foot will help with my feed problem? Thoughts?

-

Restoring OEM Stitch Length on Singer 29K70

newfieboy replied to Snakeoil's topic in Leather Sewing Machines

What were you sewing to achieve you best SPI? -

I fixed my upper threading like you suggested and turned down the foot pressure and believe it or not its a lot better! I used the skin side up at first and it feed it through a lot better. Im going to sharpen my teeth a bit and see if that helps anymore. I would say my 29k71 is feeding at 6/10. Are there any more tips you guys could let me in on? Ill try anything!

-

Sorry if quality sucks with these pics and video. The size limit is so small, I did my best! Thanks for your help BTW!! Much appreciated. Its nice to see the internet being used for some good instead of bad! Im new to the sewing world with this being my first machine. I have the PDF version of the manual but nothing else but the help from you fine people! Im use to needle and thread and 2 hands!!haha but this machine feels right in my hands and I know it can be sewing just as good as the day it was sold! Anyways thanks again ! Much love!

-

IMG_2349 .mov

-

IMG_2348 (2).mov

-

IMG_2348 (2).mov

-

The stitch on the left is me pushing a little and the stitch on the right is me hauling a little. You can see where I stopped applying pressure on the leather in the stitch on the right at the very end. It just staying in the last hole it made and makes a birds nest with the thread. It almost feels like it doesn't have enough power to pull the heavy leather through as apposed to light material. With that said there seems to be enough down force on the leather judging by the ability to see the marks from the foot. Also the stitch isn't even as I apply different amounts of force each stitch. Almost unusable on final product for this reason. Im sure im not getting the recommended stitches per inch but one problem at a time! lol and with my research thats a job for the torch and some brazing rod.

-

could wear be a factor?

-

Singer 29K58, 29K62, 29K71 Instruction Manual

newfieboy replied to Constabulary's topic in Leather Sewing Machines

could you sent the manuals to steve_warren03@outlook.com Thanks! -

Thanks for the help jimi but that doesnt work either. It starts feeding the leather in about 2-3 stitches then it just get suck in the hole that it just made. I have tired messing around with the material pressure via the large spring with no luck. I have the 71.72.73 manuals but unless im missing something the manuals do no provide a fix. im as a loss!